billyjp2

NAXJA Forum User

- Location

- Indian Orchard MA

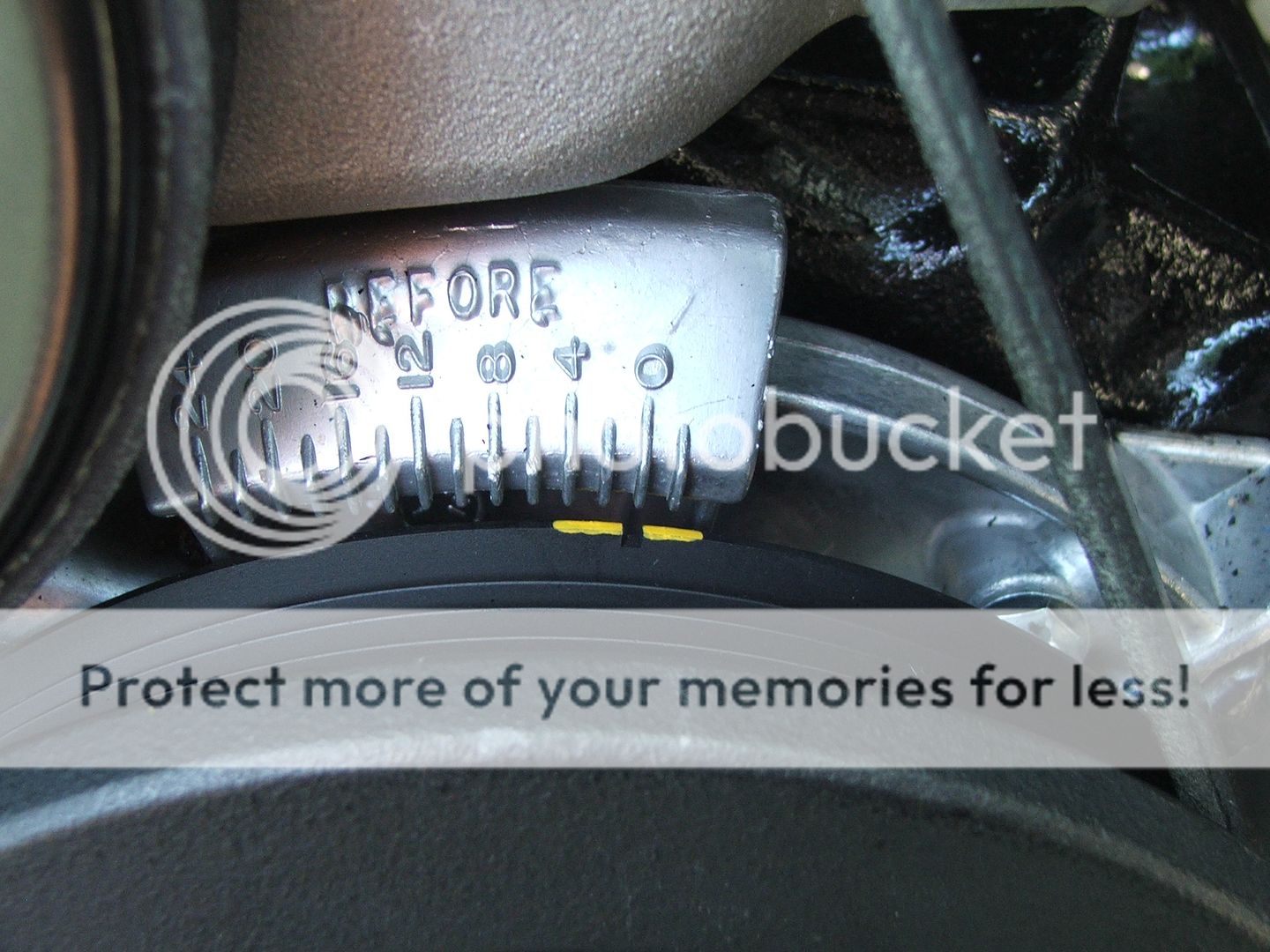

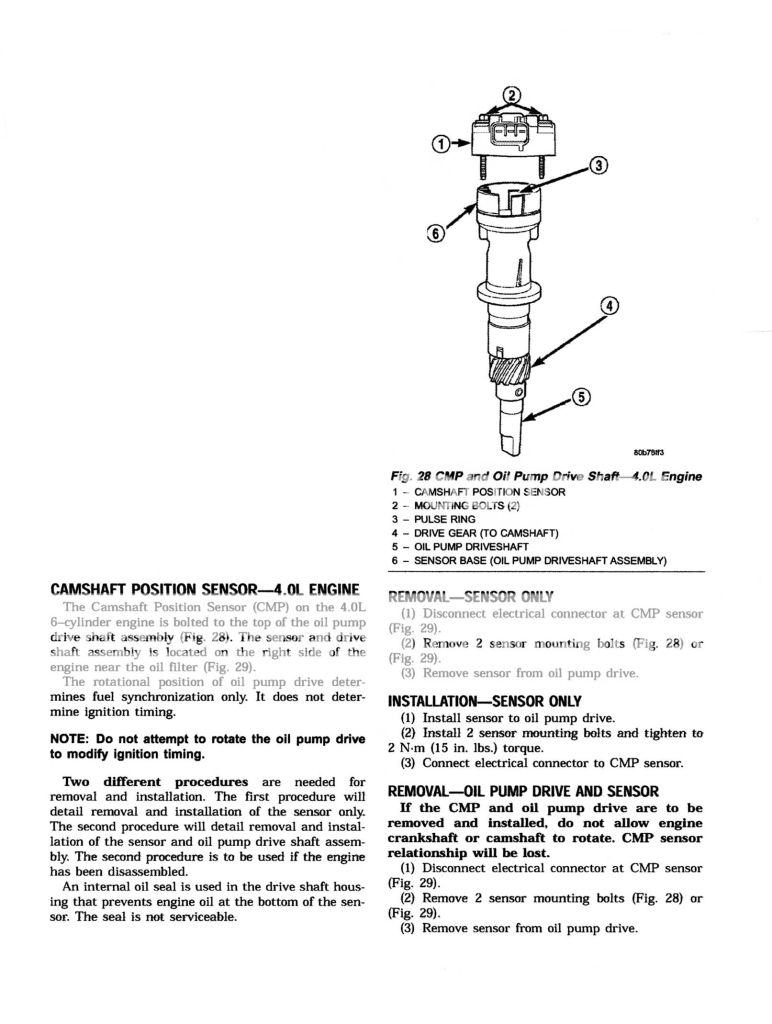

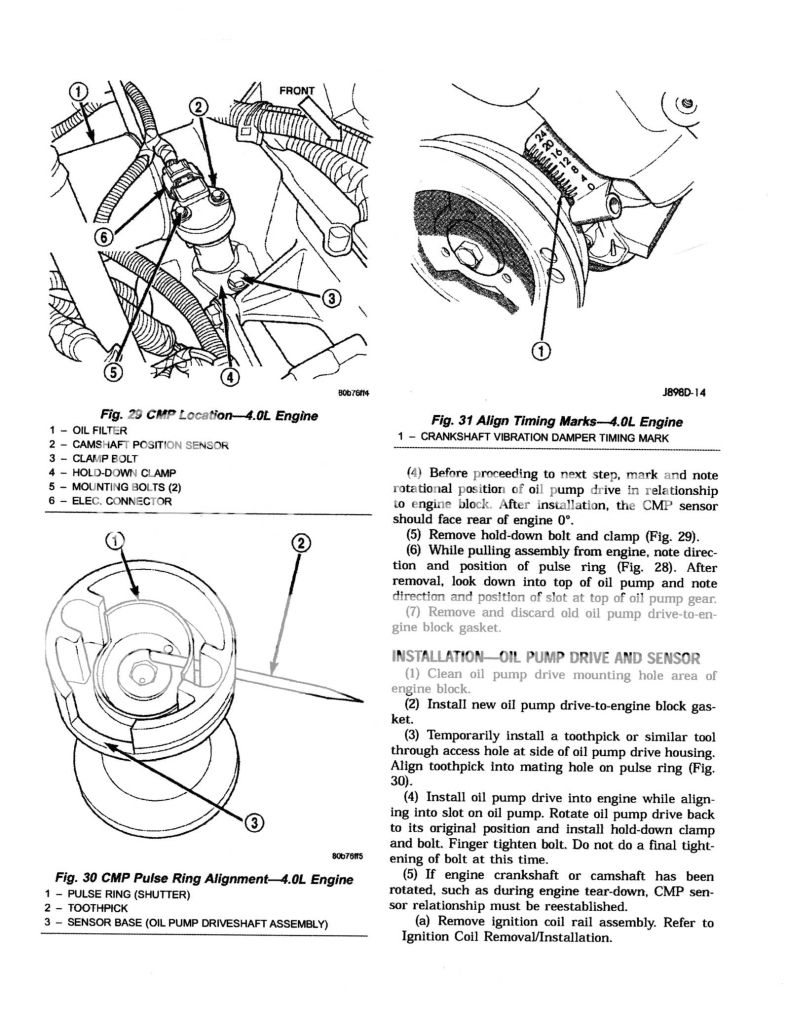

I recently swapped a 98 4.0L into a 2000 XJ. After doing some reading and researching I know I have the cam sensor installed properly in place of the distributor. When I went to start the engine it will crank but not start. It only backfires out of the intake. I know this points to clocking the cam sensor wrong but I've aligned it multiple times with the same result, even trying 180 degrees off to make sure I wasn't crazy. I also popped in a new cam sensor off a different jeep.

What else could my problem be? Any chance I'm missing a ground somewhere? I've checked fuel pressure and it's within spec.

What else could my problem be? Any chance I'm missing a ground somewhere? I've checked fuel pressure and it's within spec.