Cache96

NAXJA Forum User

- Location

- holtville Ca

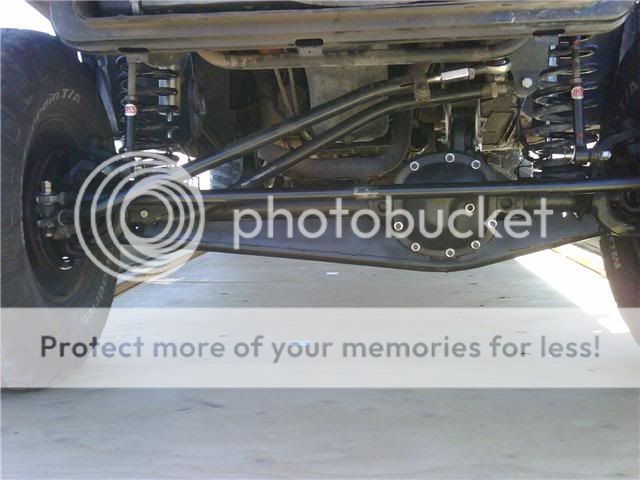

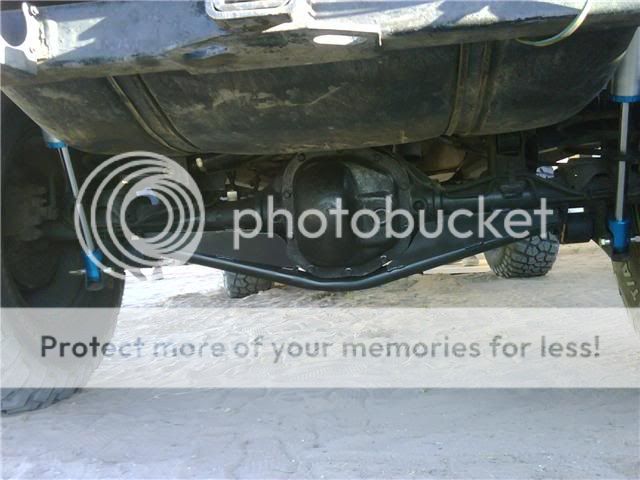

Whats up fellas, thought i would share some pics with you guys. trussed front and rear axles (HP30)-(D44a) with 4.56 gears. finished rear shock cage.

Finished up the front and rear diffs, the pic of the front diff was taking from behind, thats why it looks a little weird.it pretty much looks like the rear.

Starting

R&P with master install kits (not shown)

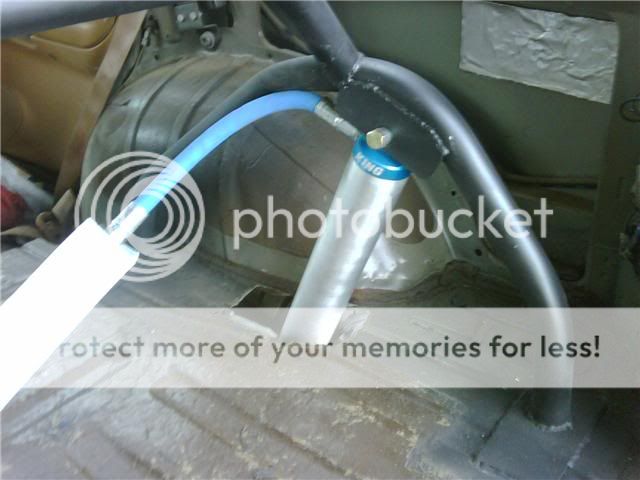

here is the rear shock hoop, eventually i will tie in my cage onto it.

And the rear shocks ...they are 16" travel 2.5" King shocks

...they are 16" travel 2.5" King shocks

Finished up the front and rear diffs, the pic of the front diff was taking from behind, thats why it looks a little weird.it pretty much looks like the rear.

Starting

R&P with master install kits (not shown)

here is the rear shock hoop, eventually i will tie in my cage onto it.

And the rear shocks

Last edited: