2000 xj 4.0L automatic.

265,000 kms

In canada, no cali or fed emissions

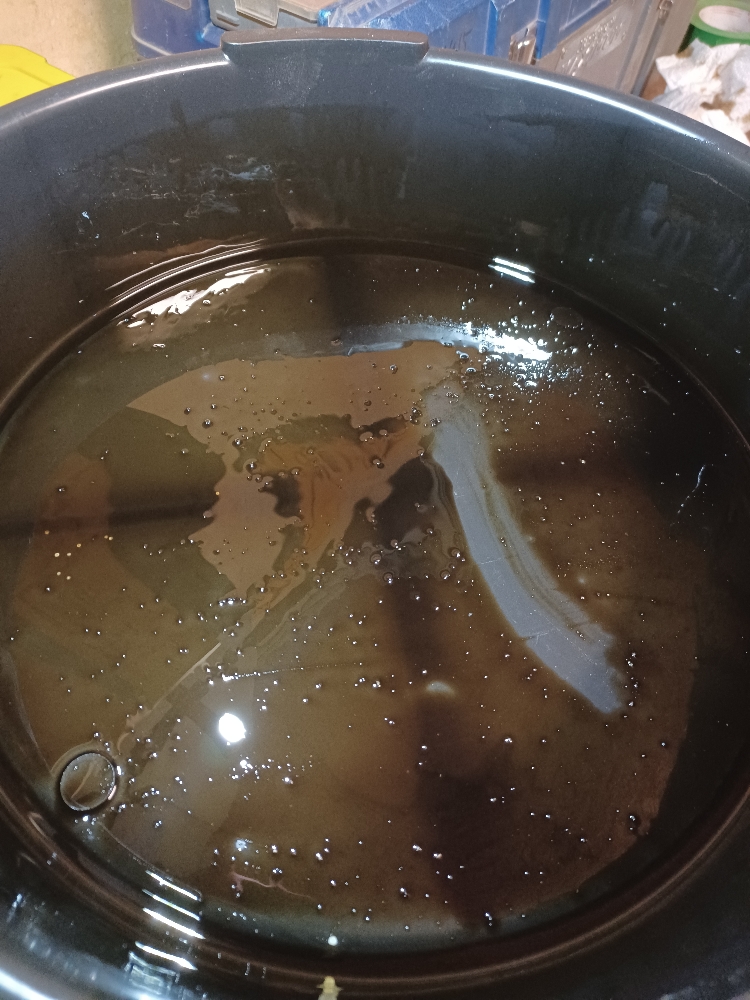

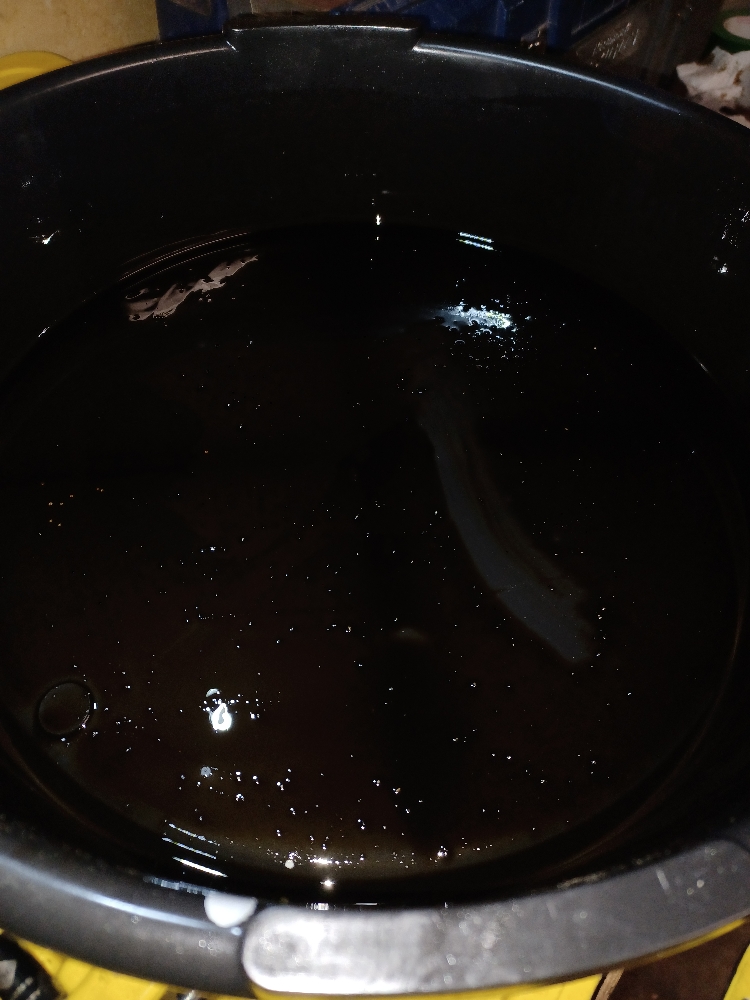

Ive through the threads on here and i still have a few questions. I changed my oil last week and found significant metal chunkys in the bottom of my oil tray. I have owned the jeep for less than 50,000 kms. I do not know its history. There was always a light knock in the engine, i assumed it was a lifter tick and didnt really examine it. After i found the metal i listened closely and it is coming from bottom end. I cut the filter open and it had no chunks in it. I always add lucas stabilizer when i change my oil (every 5,000-8000kms)

Based on this i am planning on buying a used replacement engine, preparing it as best i can before it needs to go in, and when my engine goes ill have a motor ready and i wont be in a panic.

I have swapped motors before but it has been on older models and they have always been standard transmissions.

I can find both an engine from 97-99 and a tupy head at a local jeep junk yard.

My questions are these:

1) any other compatibility issues that may creep up with these newer engines?

2) anything i should know when disconnecting an auto trans, and if the replacement engine is from a standard is there anything i need to transfer over? (Iirc there is a flex plate in addition to the flywheel)

3) since ill have the engine on a stand for a while (hopefully) what can i do to it while its out to make it last longer. As in gaskets, timing chain etc? Budget is tight but if there is something that should definitely be done while the motor is out id like to do it.

4) any other tips, tricks, advice or youtube videos i should watch?

Sent from my SM-A326W using Tapatalk

265,000 kms

In canada, no cali or fed emissions

Ive through the threads on here and i still have a few questions. I changed my oil last week and found significant metal chunkys in the bottom of my oil tray. I have owned the jeep for less than 50,000 kms. I do not know its history. There was always a light knock in the engine, i assumed it was a lifter tick and didnt really examine it. After i found the metal i listened closely and it is coming from bottom end. I cut the filter open and it had no chunks in it. I always add lucas stabilizer when i change my oil (every 5,000-8000kms)

Based on this i am planning on buying a used replacement engine, preparing it as best i can before it needs to go in, and when my engine goes ill have a motor ready and i wont be in a panic.

I have swapped motors before but it has been on older models and they have always been standard transmissions.

I can find both an engine from 97-99 and a tupy head at a local jeep junk yard.

My questions are these:

1) any other compatibility issues that may creep up with these newer engines?

2) anything i should know when disconnecting an auto trans, and if the replacement engine is from a standard is there anything i need to transfer over? (Iirc there is a flex plate in addition to the flywheel)

3) since ill have the engine on a stand for a while (hopefully) what can i do to it while its out to make it last longer. As in gaskets, timing chain etc? Budget is tight but if there is something that should definitely be done while the motor is out id like to do it.

4) any other tips, tricks, advice or youtube videos i should watch?

Sent from my SM-A326W using Tapatalk