Cherokeekid88

NAXJA Forum User

- Location

- North Carolina

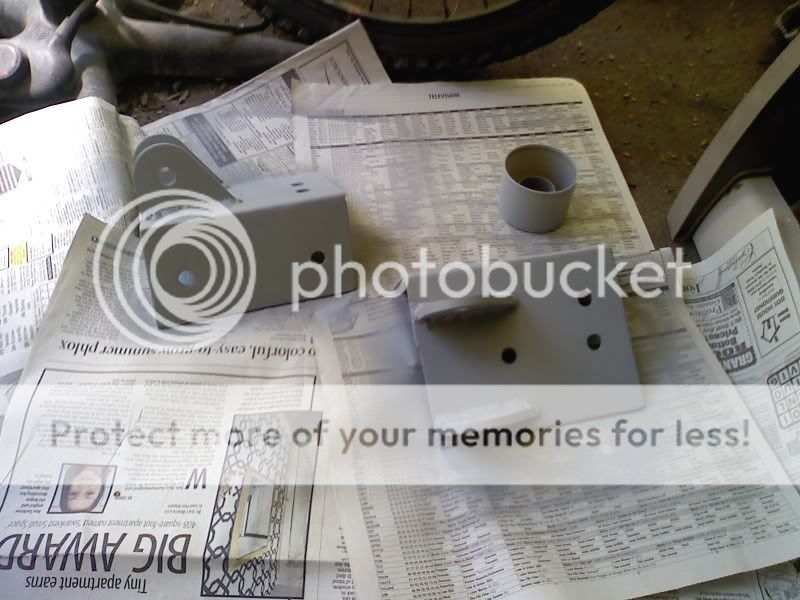

So im in the process of building some new mounts for my long arms. Currently I have basically a box welded on the bottom of the frame rail with the arm mounted inside it. Very strong, but was just temp. I have a design that is based off the Teraflex long arm mounts. which is basically a right angle mount with tabs welded on the bottom and bolted to the frame. NOW, here is my question for all of you. What is the best method for mounting this mount? I really don't want to weld it to the frame. I would like to just do some self tapping bolts, but it seems to me, that the bolts are not going to have much to bite to. (Im using 3/16" steel plate plus the thickness of the frame rail) I could also go the route of just drilling holes and then drilling access holes and using nuts with the bolts and bolt them in that way....

I know of people who run the teraflex upgrade with no problems, but just wondered if there was a way I could improve it.

I know of people who run the teraflex upgrade with no problems, but just wondered if there was a way I could improve it.