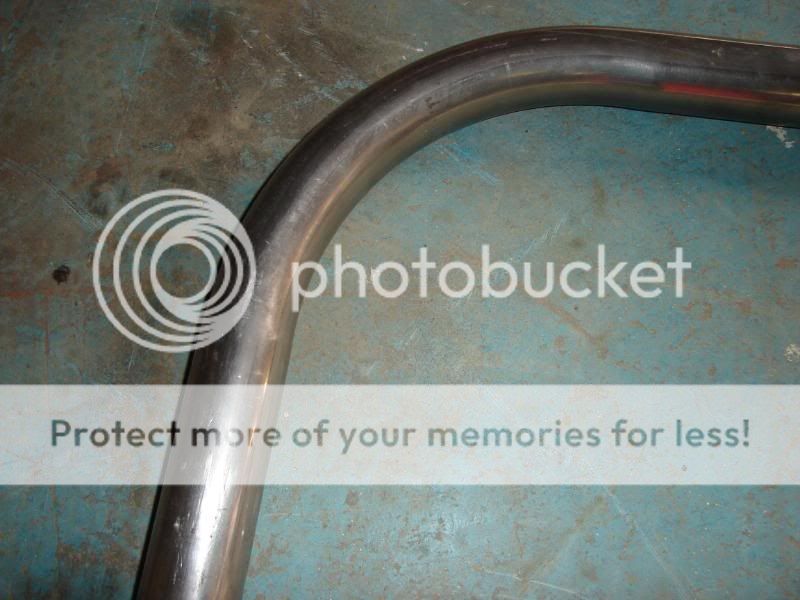

I started building my Pro-tools HMP-200 with the plans I got from them some time ago. I needed a bender that I could use to make bumpers, cages, and what not for my vehicles(jeep,prerunner,bronco).

Here it goes.

I had the side plates made from 3/8" steel rather then the 3/4" or whatever aluminum that pro-tools uses because steel is easier to come by. I had the guys at my dads work program it in and burn them out.

I got an HF air/hyrdo 12ton ram instead of the 20 ton pump jack the plans call for. I saved some money and I figure if it does'nt work I have a use for it. I can always buy the 20ton later. One thing to not is that the return springs for the ram are pretty close to what the bender plans call for and they come with some nice eyelets that I will use too.

I used 1/2" black pipe for the stabilizer tubes. The 9" long .5" bolts fit through the pipe nicely.

I cut the stabilizer tubes at the specified 7"

I went to a nut and bolt supply and got the 9" long 1" bolt for the die pivot.

I am waiting on some pieces for my roller, roller block,roller pin, and base plate.

I need to source some 1.5"x.25wall dom for my die pivot.

I will have a working total of my budget bender tomorrow.

Here it goes.

I had the side plates made from 3/8" steel rather then the 3/4" or whatever aluminum that pro-tools uses because steel is easier to come by. I had the guys at my dads work program it in and burn them out.

I got an HF air/hyrdo 12ton ram instead of the 20 ton pump jack the plans call for. I saved some money and I figure if it does'nt work I have a use for it. I can always buy the 20ton later. One thing to not is that the return springs for the ram are pretty close to what the bender plans call for and they come with some nice eyelets that I will use too.

I used 1/2" black pipe for the stabilizer tubes. The 9" long .5" bolts fit through the pipe nicely.

I cut the stabilizer tubes at the specified 7"

I went to a nut and bolt supply and got the 9" long 1" bolt for the die pivot.

I am waiting on some pieces for my roller, roller block,roller pin, and base plate.

I need to source some 1.5"x.25wall dom for my die pivot.

I will have a working total of my budget bender tomorrow.