- Location

- Thornton, CO

Alright, so this is the second incarnation of this type of axle to go under the rig. Little backstory here, I'll show you version one.

Here is the start of the first one.

I set is up with Superior 4.88s, Detroit TruTrac, Alloy USA Alloys, and TeraFlex Discs.

The Tera kit didn't last long. I don't have the pics handy at the moment. But basically the spacers deformed, pushed the backing plates in to the rotors and just destroyed the kit. I sold the backing plates and alloys to a friend at that point and just threw the stock drums and shaft back on.

A couple months later I hit the road for Colorado Fest 2007 at the end of July that year. We were about 10 miles out of Montrose headin' down the highway when the back starts poppin bad. My first thought is I spit a joint on the shaft. Just as I start to tap the brakes and move right, off the road, the rearend locks up. Did a 180º spin off the highway at 70 mph. Slid right into someone's driveway between a 6' deep drainage ditch on either side of it. Had my angel with me that day.

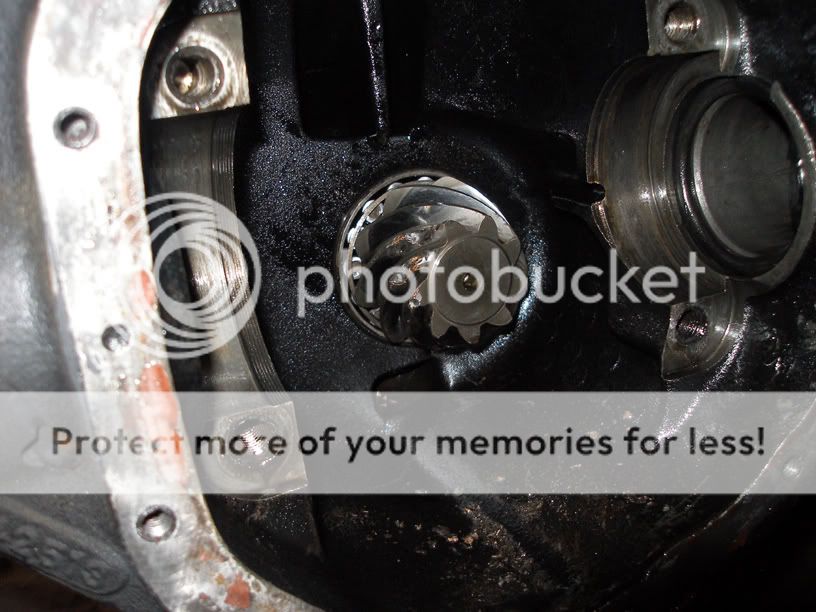

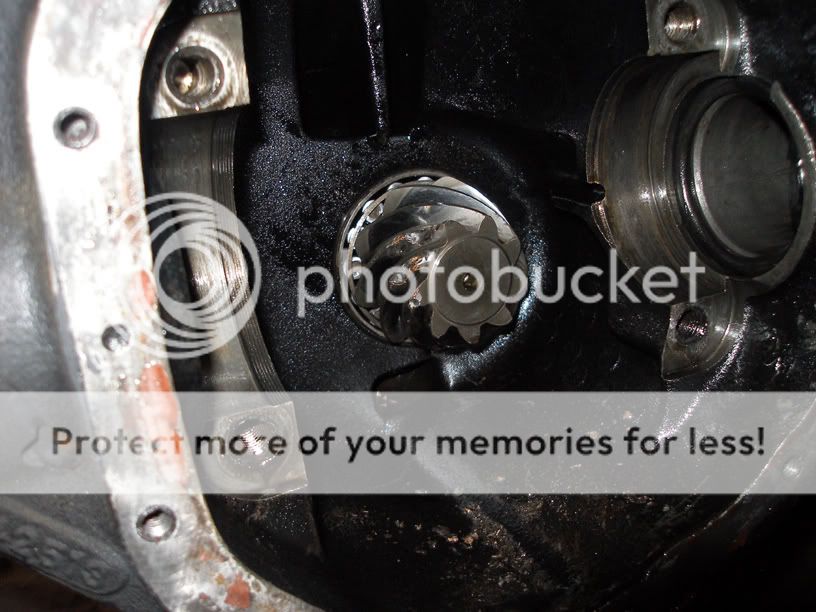

Basically the TT has a block that serves as a centerpin. It just bolts in to the TT. When my installer setup the gears, he (speculating here) saw the block was already bolted in and didn't check the torque spec on it. So after time it worked it's way loose. Until right outside of Montrose it let go and sent that chunk of steel bouncing around in the diff. Chewed teeth off of both gears, twisted the splines, and took out a chunk of the inner webbing. The drivers side end flange also had an incurable leak, so I just scraped it.

Well my XJ was my DD at the time and I needed to be mobile asap. So after we got back from the trip we swapped a D35 under. I drove this way, without 4x4 for a little more than a year. In the meantime I acquired another stock 44 and started over.

End result is as follows:

Powder Coated Semi-Gloss Black

33 Spline Alloy USAs

ARB

Precision 4.88s

Yukon U-Bolt Yoke

Crane Cover

Wilwood Disc Brakes

Custom Stainless Braided Lines

M.O.R.E. Ebrake Cables

:guitar:

Here is the start of the first one.

I set is up with Superior 4.88s, Detroit TruTrac, Alloy USA Alloys, and TeraFlex Discs.

The Tera kit didn't last long. I don't have the pics handy at the moment. But basically the spacers deformed, pushed the backing plates in to the rotors and just destroyed the kit. I sold the backing plates and alloys to a friend at that point and just threw the stock drums and shaft back on.

A couple months later I hit the road for Colorado Fest 2007 at the end of July that year. We were about 10 miles out of Montrose headin' down the highway when the back starts poppin bad. My first thought is I spit a joint on the shaft. Just as I start to tap the brakes and move right, off the road, the rearend locks up. Did a 180º spin off the highway at 70 mph. Slid right into someone's driveway between a 6' deep drainage ditch on either side of it. Had my angel with me that day.

Basically the TT has a block that serves as a centerpin. It just bolts in to the TT. When my installer setup the gears, he (speculating here) saw the block was already bolted in and didn't check the torque spec on it. So after time it worked it's way loose. Until right outside of Montrose it let go and sent that chunk of steel bouncing around in the diff. Chewed teeth off of both gears, twisted the splines, and took out a chunk of the inner webbing. The drivers side end flange also had an incurable leak, so I just scraped it.

Well my XJ was my DD at the time and I needed to be mobile asap. So after we got back from the trip we swapped a D35 under. I drove this way, without 4x4 for a little more than a year. In the meantime I acquired another stock 44 and started over.

End result is as follows:

Powder Coated Semi-Gloss Black

33 Spline Alloy USAs

ARB

Precision 4.88s

Yukon U-Bolt Yoke

Crane Cover

Wilwood Disc Brakes

Custom Stainless Braided Lines

M.O.R.E. Ebrake Cables

:guitar: