spikyhair87

NAXJA Forum User

- Location

- IL

ok i have searched and only found one thread that has some info and im

looking for more info on the way people have mounted their winches to the

front crossmember area/behind their bumper...

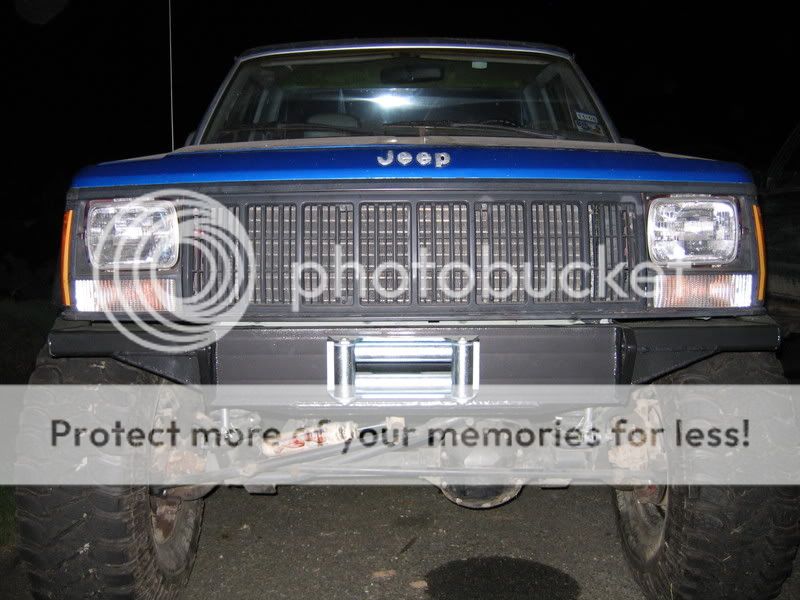

currently i have a jcr stage 3 front bumper and am thinking that i can cut out the front cross member and reinforce it with some 1/8-1/4 plate with gussets or something.. and mount the winch directly to the back of the bumper after i "poke"a hole through (have sort of a rectangle shape hole) for the winch cable and mount the fairlead directly to the front of the bumper...the fairlead "covers" up the hole... etc..

sort of hard to explain... its all up top here... (Mechanical Engineer by trade)... but im looking for pictures/ideas/possible problems...

btw its a xrc8 winch and i do have ample welding skills etc..

Thanks!

looking for more info on the way people have mounted their winches to the

front crossmember area/behind their bumper...

currently i have a jcr stage 3 front bumper and am thinking that i can cut out the front cross member and reinforce it with some 1/8-1/4 plate with gussets or something.. and mount the winch directly to the back of the bumper after i "poke"a hole through (have sort of a rectangle shape hole) for the winch cable and mount the fairlead directly to the front of the bumper...the fairlead "covers" up the hole... etc..

sort of hard to explain... its all up top here... (Mechanical Engineer by trade)... but im looking for pictures/ideas/possible problems...

btw its a xrc8 winch and i do have ample welding skills etc..

Thanks!