-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

- Home

- Forums

- NAXJA Unibody Jeep Technical Forums

- Jeep Cherokee XJ (1984 - 2001)

- Modified Tech Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How long should my lower control arms be?

- Thread starter D sanchez

- Start date

builder

NAXJA Forum User

- Location

- Yucca Valley california

mbogosia

NAXJA Forum User

- Location

- Nashville, TN

Even with Yuccamans site, it just depends. You need to get your pinion angle as close to the driveshaft angle as you can to reduce vibrations. This of course effects caster.

builder

NAXJA Forum User

- Location

- Yucca Valley california

Yucca mans site get's you in the ball park. you may need to tweek a little either way! start there and adjust as needed.

mbogosia

NAXJA Forum User

- Location

- Nashville, TN

yeah, I went with the 16.33" and I need to shorten mine to around 16" Pinion angle is just too off and it is causing a vibration.

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

It makes no difference,what you built is a NIGHTMARE!

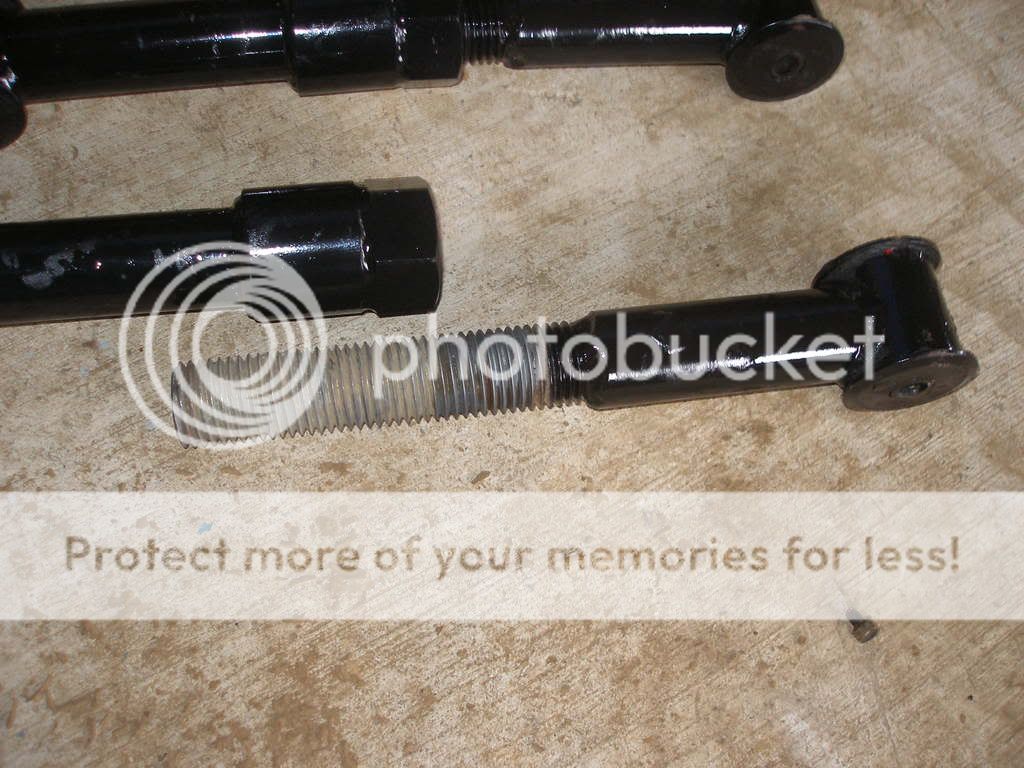

Critisism is somthing i have no problem with. Please tell me what problems you see with my lowers. And what i can do to correct the problem.

I am not atall looking for a fight, just some advise and input. I joind this site for just that. I figured allot of guys running XJs could help me out.

Thanks for the help.

I am not atall looking for a fight, just some advise and input. I joind this site for just that. I figured allot of guys running XJs could help me out.

Thanks for the help.

beakie

NAXJA Forum User

- Location

- Ontario, Canada

not sure why he criticised, but I would think you'd want some kind of locking nut on those.

a locking nut would keep the adjustable thread from twisting and such during articulation. not to mention with those large threads it would keep them from wearing out so quickly since the way you have them they will be pushing in/out with every bump on the road.

just IMO tho.

a locking nut would keep the adjustable thread from twisting and such during articulation. not to mention with those large threads it would keep them from wearing out so quickly since the way you have them they will be pushing in/out with every bump on the road.

just IMO tho.

I only have a nut on one side because the rotation of the bolt to the nut would eliminate tention aginst the bushing. If you have bushings on both ends, then when one side is low and the other side high, then your under a bind. This way one end can rotate, and relieve some of the bind.

Yes the threads are coarse, but i dont see a 1 1/2" thread wearing out any time soon.

Thanks for the input:roll:

Yes the threads are coarse, but i dont see a 1 1/2" thread wearing out any time soon.

Thanks for the input:roll:

beakie

NAXJA Forum User

- Location

- Ontario, Canada

there is a reason all manufacturers use a locking nut on their adjustable arms.

the rotation your talking about is meant to be loaded onto the bushings, whether they rubber, JJ, or what have you.

the purpose of the locking nut is from keeping the threads from moving around inside the large nut you seem to have welded on there. another nut which would lock down that threaded rod at the exact length you require would be very beneficial.

try those arms just the way they are for a few weeks and then try un-threading them. I expect it won't be easy.

the rotation your talking about is meant to be loaded onto the bushings, whether they rubber, JJ, or what have you.

the purpose of the locking nut is from keeping the threads from moving around inside the large nut you seem to have welded on there. another nut which would lock down that threaded rod at the exact length you require would be very beneficial.

Yes the threads are coarse, but i dont see a 1 1/2" thread wearing out any time soon.

try those arms just the way they are for a few weeks and then try un-threading them. I expect it won't be easy.

Why would you think the threads will be tougher in the future?

The movement of the suspension will wear the threads out in no time. I considered doing the samething that you did. Search for adjustable control arms and look at the threads. They are very fine and with a lock nut.

gorman

NAXJA Forum User

- Location

- South Africa

You will definately have a noisy ride with lots of cluncks without a locknut. The JKS control arms work like that without a lock nut but they have untrafine threads, a bush on the inside and they are pumped full of grease absorb some movement and noise. I'd suggest you fit a locknut and then loosen it when you go offroad, but keep it locked on the road.

In term of the adjusting lengths. I recently installed adjustable short arms in the stock locations with a 6" lift. At first I set everything according to Yucca-Man's website which says it should be 17" for the lowers and 15.5" for the uppers. That combination gave me caster of 11 degrees with the pinion pointing downward from horisontal (I didn't have a driveshaft fitted at the time, but it would have been horrible vibrations). I liked how the lower control arms positioned the wheels nicely in the centre of the wheel wells, so I kept their lengths as they were at 17" and extended the top ones as far as I safely could. On an alignment machine afterwards this gave me a caster of 5.30 degrees and the pinion/driveshaft angle at around or just under 5 degrees. This works well in terms of handling and I have no noticable vibrations. Now, to remember what the lengths of the upper control arms were???? I'm under correction, but I think they turned out to be also set at about 17" - somehow I have the figure of 430mm stuck in my mind, I'll measure and if it is something completely different I'll post back here..

What I can say is that at 6" lift with short arms in the stock position one would ideally want drop brackets or long arms.

This what the angle look like!

In term of the adjusting lengths. I recently installed adjustable short arms in the stock locations with a 6" lift. At first I set everything according to Yucca-Man's website which says it should be 17" for the lowers and 15.5" for the uppers. That combination gave me caster of 11 degrees with the pinion pointing downward from horisontal (I didn't have a driveshaft fitted at the time, but it would have been horrible vibrations). I liked how the lower control arms positioned the wheels nicely in the centre of the wheel wells, so I kept their lengths as they were at 17" and extended the top ones as far as I safely could. On an alignment machine afterwards this gave me a caster of 5.30 degrees and the pinion/driveshaft angle at around or just under 5 degrees. This works well in terms of handling and I have no noticable vibrations. Now, to remember what the lengths of the upper control arms were???? I'm under correction, but I think they turned out to be also set at about 17" - somehow I have the figure of 430mm stuck in my mind, I'll measure and if it is something completely different I'll post back here..

What I can say is that at 6" lift with short arms in the stock position one would ideally want drop brackets or long arms.

This what the angle look like!

beakie

NAXJA Forum User

- Location

- Ontario, Canada

This what the angle look like!

off topic, but that zerk work last long there. any chance that bushing can be flipped so the zerk is at the top, or the whole arm flipped maybe?

on topic,

I mentioned the threads becoming hard to turn because when I let the locking nut go loose on my RE adjustable upper it required a 4' breaker bar to remove the adj piece. not sure how long it was loose, but it couldn't have been long.

your getting it, take it in.Thank you for your input. Im not looking to argue, but good input is what im after. Cheers.

gorman

NAXJA Forum User

- Location

- South Africa

I wondered about the zerk being in that spot - but I wanted to be able to reach it while installed. Maybe I should just turn the control arm around so that the JJ sits on the body end and the OE rubber bushing on the axle end?

beakie

NAXJA Forum User

- Location

- Ontario, Canada

Maybe I should just turn the control arm around so that the JJ sits on the body end and the OE rubber bushing on the axle end?

yes, yes you do want to do that.

muddeprived

NAXJA Forum User

- Location

- PA

You will definately have a noisy ride with lots of cluncks without a locknut. The JKS control arms work like that without a lock nut but they have untrafine threads, a bush on the inside and they are pumped full of grease absorb some movement and noise. I'd suggest you fit a locknut and then loosen it when you go offroad, but keep it locked on the road.

In term of the adjusting lengths. I recently installed adjustable short arms in the stock locations with a 6" lift. At first I set everything according to Yucca-Man's website which says it should be 17" for the lowers and 15.5" for the uppers. That combination gave me caster of 11 degrees with the pinion pointing downward from horisontal (I didn't have a driveshaft fitted at the time, but it would have been horrible vibrations). I liked how the lower control arms positioned the wheels nicely in the centre of the wheel wells, so I kept their lengths as they were at 17" and extended the top ones as far as I safely could. On an alignment machine afterwards this gave me a caster of 5.30 degrees and the pinion/driveshaft angle at around or just under 5 degrees. This works well in terms of handling and I have no noticable vibrations. Now, to remember what the lengths of the upper control arms were???? I'm under correction, but I think they turned out to be also set at about 17" - somehow I have the figure of 430mm stuck in my mind, I'll measure and if it is something completely different I'll post back here..

What I can say is that at 6" lift with short arms in the stock position one would ideally want drop brackets or long arms.

This what the angle look like!

Are those Rough County's arms? I just got a set today and that's what they look like. The new arms are sweet. Another thing, i thought the flex joint was supposed to be on the frame side? At least that's what the instructions say. (it really shouldn't matter right?)

Similar threads

- Replies

- 24

- Views

- 425

- Replies

- 28

- Views

- 1K

- Replies

- 8

- Views

- 171