mk153smaw

NAXJA Forum User

- Location

- Fort Lee, Va

Ok Gentleman, Ladies

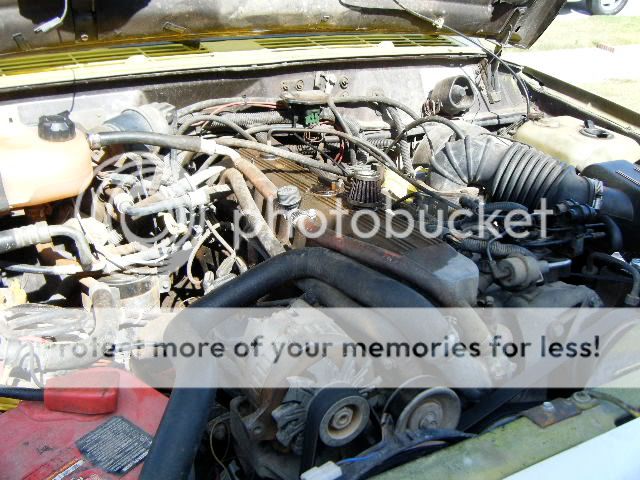

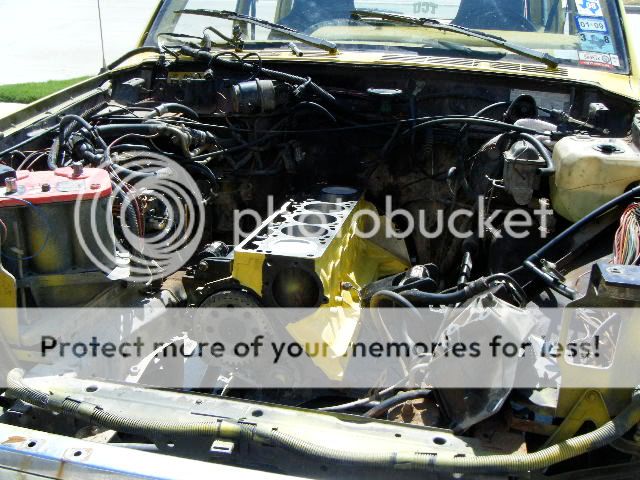

Project 5.0 (it really is an 5.0ish might be 5.1) gets installed beginning today. It is well before orginall plan due to the my core dying on me recently this week.

I just finished painting the block and head Daytona Yellow in time luckily and some of the stuff got in from Hesco last night. With luck the water pump will make it today.

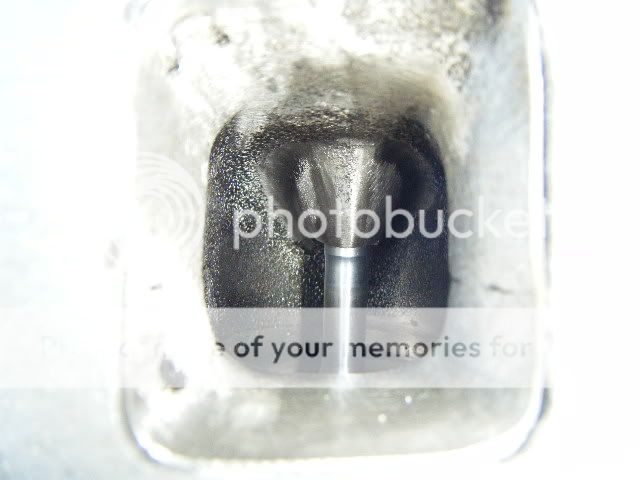

For those that don't know the motor. What makes it a 5.0? 4" pistons 4.06 crank (yes I paid for that, because I wanted to see the results) and I am using the long rod setup. We had to some very tricky adjustment of pin highth for quench, with the ideal CR to be around 8.8 to 9.2 in that zone. We want to be able to run pump gas. The math put us at 9.012, reality with gauges showed 8.9876 CR. We were very pleased with the result. We are using the Mopar performance .055 head gasket to open it up a bit which got our quench we needed.

the rest of the set-up is fairly strait forward:

Harland Sharp Adj Roller Rockers

Comp Cams Extreme 4X4 Cam for fuel inj extended duration to remove egr

Dbl Roller Time set

Stock Distibuter (I can adjust timing on my block)

OEM Oil Pump (no need for HV pump, don't want to walk the cam)

Using the '88 intake (I'll get into that later for why)

63mm TBI (Oletshot made this for me)

Hesco HiFlow water pump

Head Work:

2.02 Manley Titanium INT Valves

1.60 Manley Titanium EXT Valves

Pontiac Springs (Had to use those to fit the valves and seats properly)

Ported and Polished the bowls and runners for flow. To include shaving down the valve guides aerodynamicly.

Increased and reshaped cylinderhead combustion chamber area for better burn.

Gasket matched ports to the intake to lessen restrictive flows.

Machine work and parts just at the shop = $5000 parts from me ..... dont even ask. How long has this taken to put together? Hmmm been a while really, I would say over 10 months and one military deployment to pay for it and source parts and research.

Pictures will be forthcoming starting in the next hour as I change into the overalls and Mike Gronholtz gets off work in a bit.

Anyone in the Fort Worth are is welcome to come on by this weekend and watch/help/drink beer/ BBQ at the house while we screw with this thing. The motor was not supposed to be ready and is missing some key stuff, but gotta do what ya gotta do when your in a jam.

Project 5.0 (it really is an 5.0ish might be 5.1) gets installed beginning today. It is well before orginall plan due to the my core dying on me recently this week.

I just finished painting the block and head Daytona Yellow in time luckily and some of the stuff got in from Hesco last night. With luck the water pump will make it today.

For those that don't know the motor. What makes it a 5.0? 4" pistons 4.06 crank (yes I paid for that, because I wanted to see the results) and I am using the long rod setup. We had to some very tricky adjustment of pin highth for quench, with the ideal CR to be around 8.8 to 9.2 in that zone. We want to be able to run pump gas. The math put us at 9.012, reality with gauges showed 8.9876 CR. We were very pleased with the result. We are using the Mopar performance .055 head gasket to open it up a bit which got our quench we needed.

the rest of the set-up is fairly strait forward:

Harland Sharp Adj Roller Rockers

Comp Cams Extreme 4X4 Cam for fuel inj extended duration to remove egr

Dbl Roller Time set

Stock Distibuter (I can adjust timing on my block)

OEM Oil Pump (no need for HV pump, don't want to walk the cam)

Using the '88 intake (I'll get into that later for why)

63mm TBI (Oletshot made this for me)

Hesco HiFlow water pump

Head Work:

2.02 Manley Titanium INT Valves

1.60 Manley Titanium EXT Valves

Pontiac Springs (Had to use those to fit the valves and seats properly)

Ported and Polished the bowls and runners for flow. To include shaving down the valve guides aerodynamicly.

Increased and reshaped cylinderhead combustion chamber area for better burn.

Gasket matched ports to the intake to lessen restrictive flows.

Machine work and parts just at the shop = $5000 parts from me ..... dont even ask. How long has this taken to put together? Hmmm been a while really, I would say over 10 months and one military deployment to pay for it and source parts and research.

Pictures will be forthcoming starting in the next hour as I change into the overalls and Mike Gronholtz gets off work in a bit.

Anyone in the Fort Worth are is welcome to come on by this weekend and watch/help/drink beer/ BBQ at the house while we screw with this thing. The motor was not supposed to be ready and is missing some key stuff, but gotta do what ya gotta do when your in a jam.