xjcjfreek

NAXJA Forum User

- Location

- Northern BC Canada

Started the swap the other day. Its a 1986 cherokee, 2.8L, 904 auto transmission, np228, dana 30 front, dana 35 rear. I am swaping in a 1970 Chevy 250 inline 6 and turbo 350 auto tranny.

My jeep as stock.

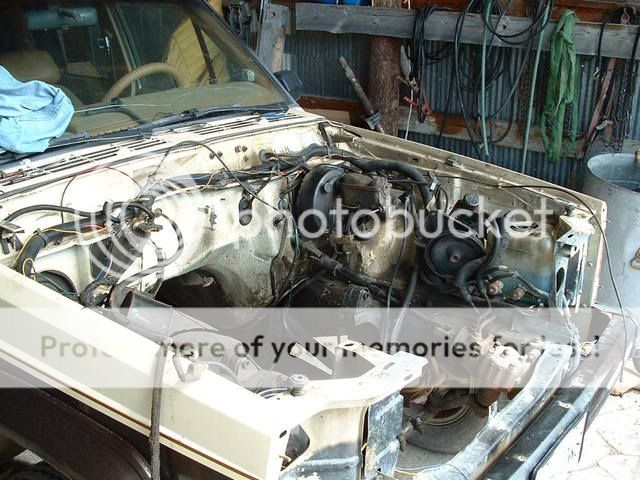

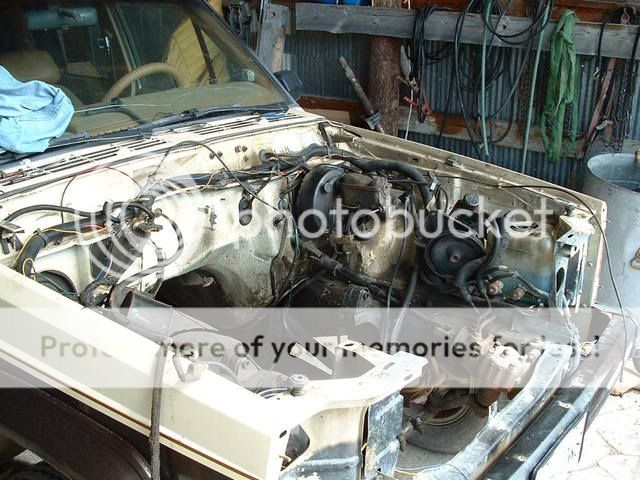

Motor, tranny and tranfer case pulled.

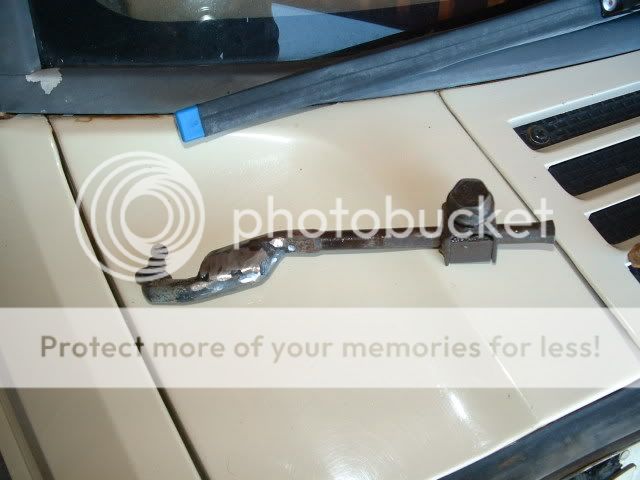

Got the stock tranny and TC cleaned up

As well as the engine compartment

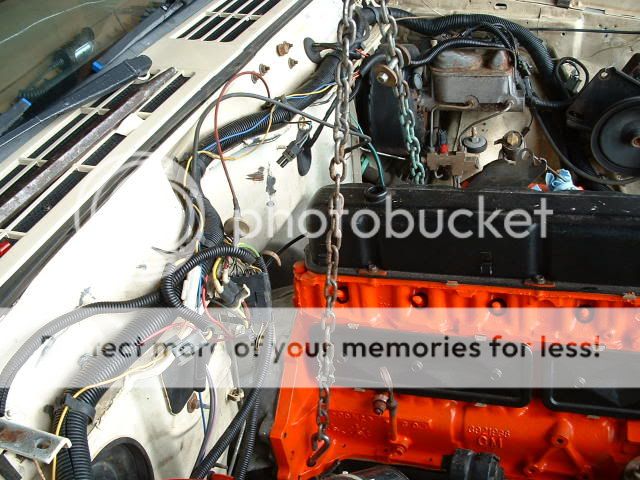

Here is my donor engine and tranny. Yes I relize the tranny is a 2 wheel drive but bear with me.

And thats as far as I have got so far. I will post more as the swap continues.

By the way, I am using an adapter from Novak to mate the turbo 350 and the np228.

My jeep as stock.

Motor, tranny and tranfer case pulled.

Got the stock tranny and TC cleaned up

As well as the engine compartment

Here is my donor engine and tranny. Yes I relize the tranny is a 2 wheel drive but bear with me.

And thats as far as I have got so far. I will post more as the swap continues.

By the way, I am using an adapter from Novak to mate the turbo 350 and the np228.