XJ Stryker

WHO DAT!

- Location

- Smiths Station, Al

So here we go.

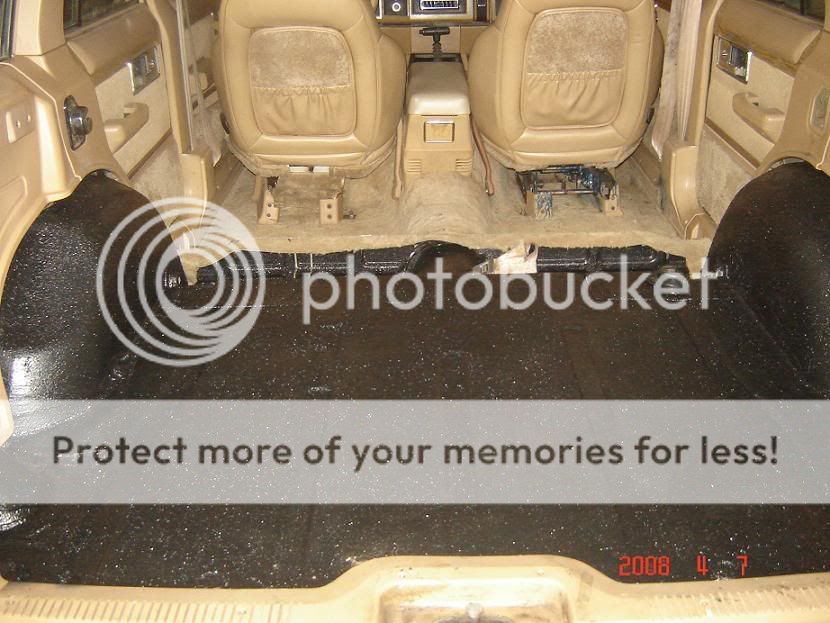

Installing a 3in RC lift and Having Problems with the Pass Front Leaf Spring mount. THe weld nut broke. SO I cut a hole.

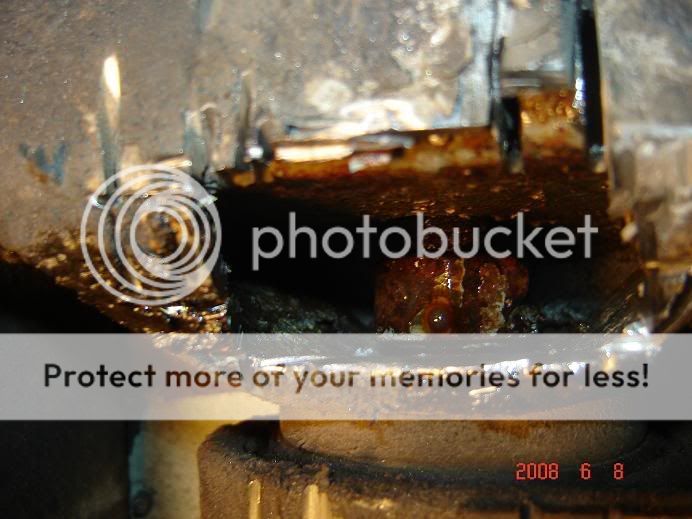

Easy no prob now I can Access the Weld nut. FYI it is NOT a 21mm on the other side. I was able to put a 15/16 on it pretty snug so it is close to that.

Ok the problem comes after I loosen it up. Seems that the bolt will not start coming out of the sleeve AT ALL. I mean it is backed up all the way against the housing. from the pic.

I cut a hole in the Frame to get a look from the other side of it.

I have turned it about 10 more threads since i took those pics and it hasnt changed any so I can safely say that the nut is no longer holding the bolt on.

I can't get a hammer or punch in there to tap it from the side with the last pic. So I cut a notch in the head of the bolt to try and PRY on it. No luck

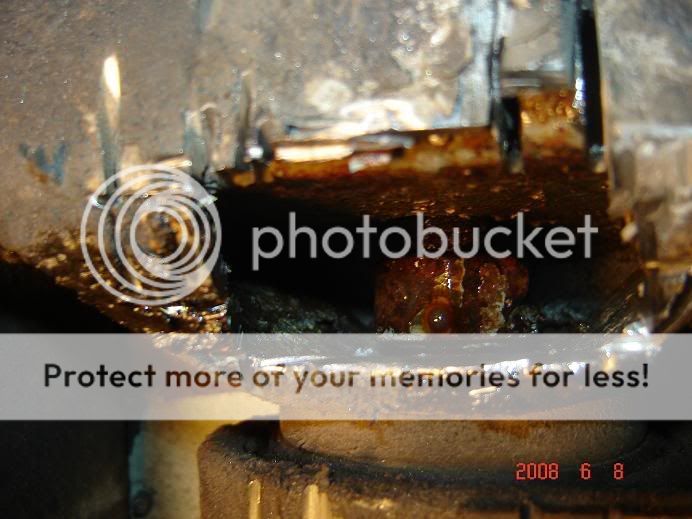

I am thinking about cutting it here.

I have no clue WHY or what to do to get this out. I cant get anything in there to cut the WELD NUT side off. If i cut it there I am thinking PRY the HELL out of the top of the spring back till I can slide it off the bolt then maybe cut it again and pull it out of the hole i cut. I dont know.

I need help.

All Idea's are welcome

NOTE: I HAVE NO WELDER

Installing a 3in RC lift and Having Problems with the Pass Front Leaf Spring mount. THe weld nut broke. SO I cut a hole.

Easy no prob now I can Access the Weld nut. FYI it is NOT a 21mm on the other side. I was able to put a 15/16 on it pretty snug so it is close to that.

Ok the problem comes after I loosen it up. Seems that the bolt will not start coming out of the sleeve AT ALL. I mean it is backed up all the way against the housing. from the pic.

I cut a hole in the Frame to get a look from the other side of it.

I have turned it about 10 more threads since i took those pics and it hasnt changed any so I can safely say that the nut is no longer holding the bolt on.

I can't get a hammer or punch in there to tap it from the side with the last pic. So I cut a notch in the head of the bolt to try and PRY on it. No luck

I am thinking about cutting it here.

I have no clue WHY or what to do to get this out. I cant get anything in there to cut the WELD NUT side off. If i cut it there I am thinking PRY the HELL out of the top of the spring back till I can slide it off the bolt then maybe cut it again and pull it out of the hole i cut. I dont know.

I need help.

All Idea's are welcome

NOTE: I HAVE NO WELDER