thebluebuffalo

NAXJA Forum User

- Location

- Kentucky

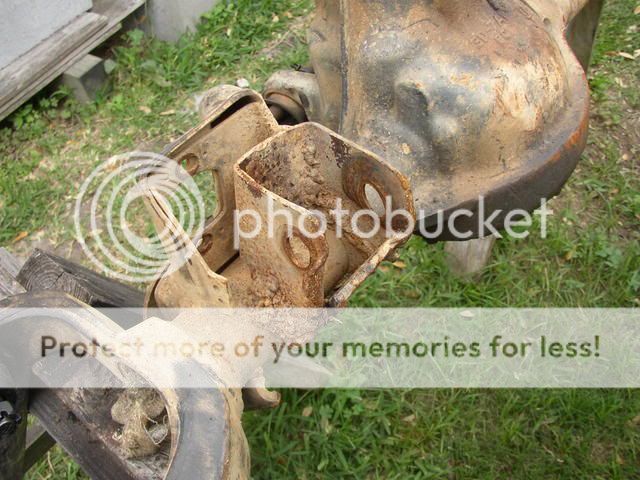

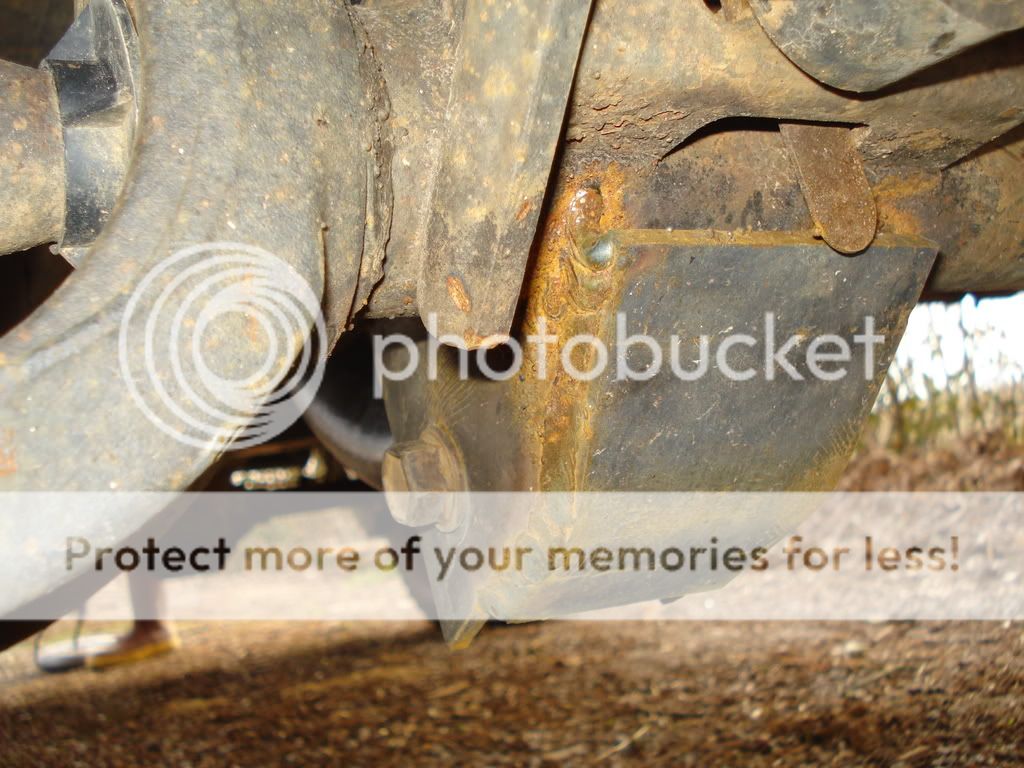

i damn near ripped off the bracket for my lower control arm on the passenger side of the axle. it's still attached for the time being. has this every happened to someone on here? how did you beef up the brackets so it wouldn't happed again? i've got pics, as soon as i can find my usb i'll post. thanks.