You shouldn't need to - once you can get your fingers behind it, it's yours.

One other thing I forgot to mention this time (I've covered this process extensively before...) is that you should, really, have a bag handy that's big enough to stick both hands in. Once you take the case half screws out, put the switch and both hands in the bag, and THEN separate the case halves. There are two contacts on a wiper arm in there, and both contacts are spring-loaded (and I don't recall the dims, I need to take another one apart and measure everything again...) Having to make one of those contacts because you lost it - or replace a spring because it went airborne - is a HUGE pain in the arse! Don't ask how I know, I shall leave that as an exercise for the apt pupil...

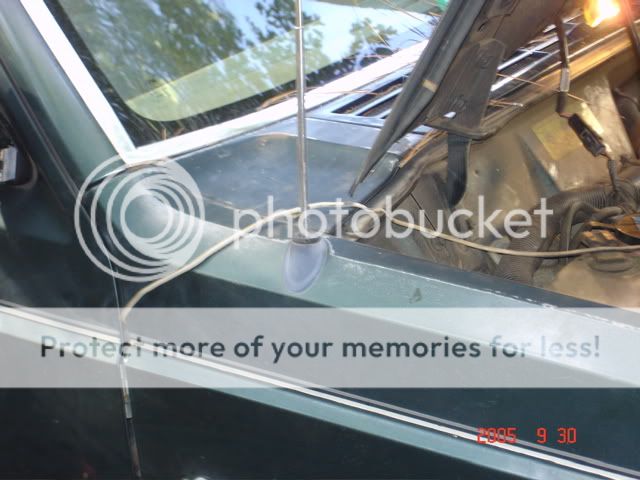

You're not really "shimming" the switch out, you're just prying on alternate sides, and using something wide enough and flexible enough that you shouldn't damage the switch assembly. DO NOT beat on it - just gently pry, it WILL come loose. It just may take time. However, you DO NOT want to break the thing, since it will cost you upwards of $300US to replace!

5-90

(Edit - OK, I didn't need to bother with "$US." I guess I got crossed up - last time I went through this, the other guy was in England...)