jjmat3

NAXJA Forum User

- Location

- Big Bear & Lancaster

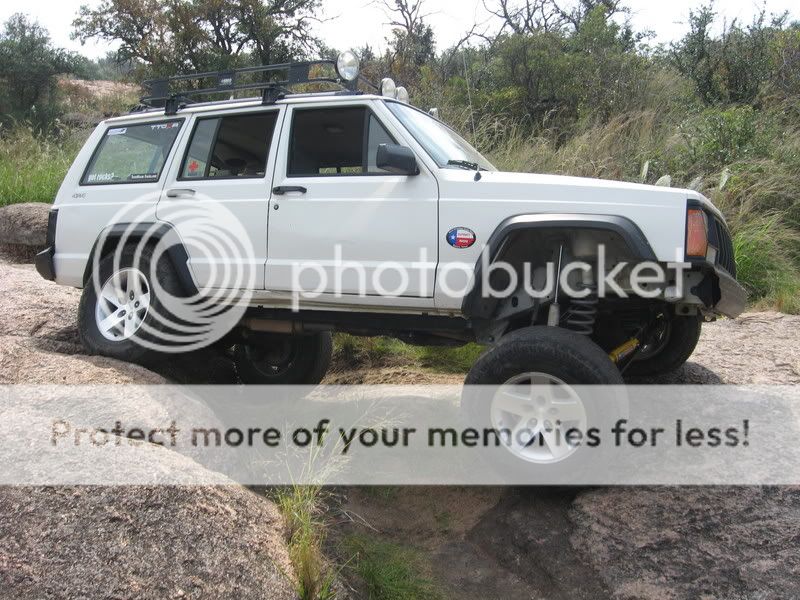

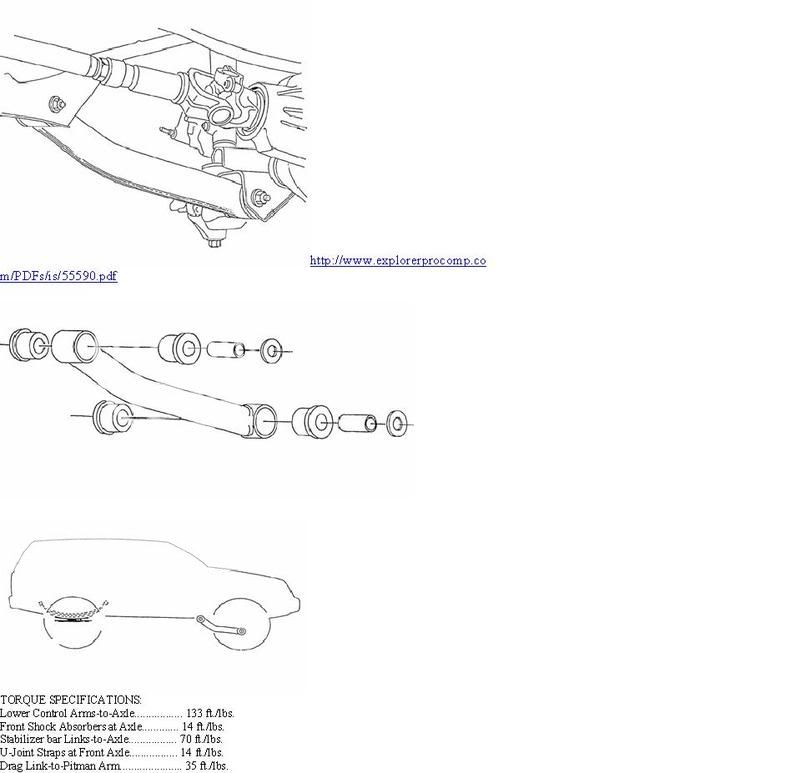

Can anyone identify what brand arms these are AND can you please tell me which way they should mount?

Bent end toward axle or longer side toward axle? I am assuming the bend goes downward as that appears how they were previously installed on the Jeep they came from due to the scratches on that side.

Any help would be appreciated. Thanks.

Bent end toward axle or longer side toward axle? I am assuming the bend goes downward as that appears how they were previously installed on the Jeep they came from due to the scratches on that side.

Any help would be appreciated. Thanks.