MrShoeBoy

NAXJA Forum User

- Location

- Cincinnati, OH

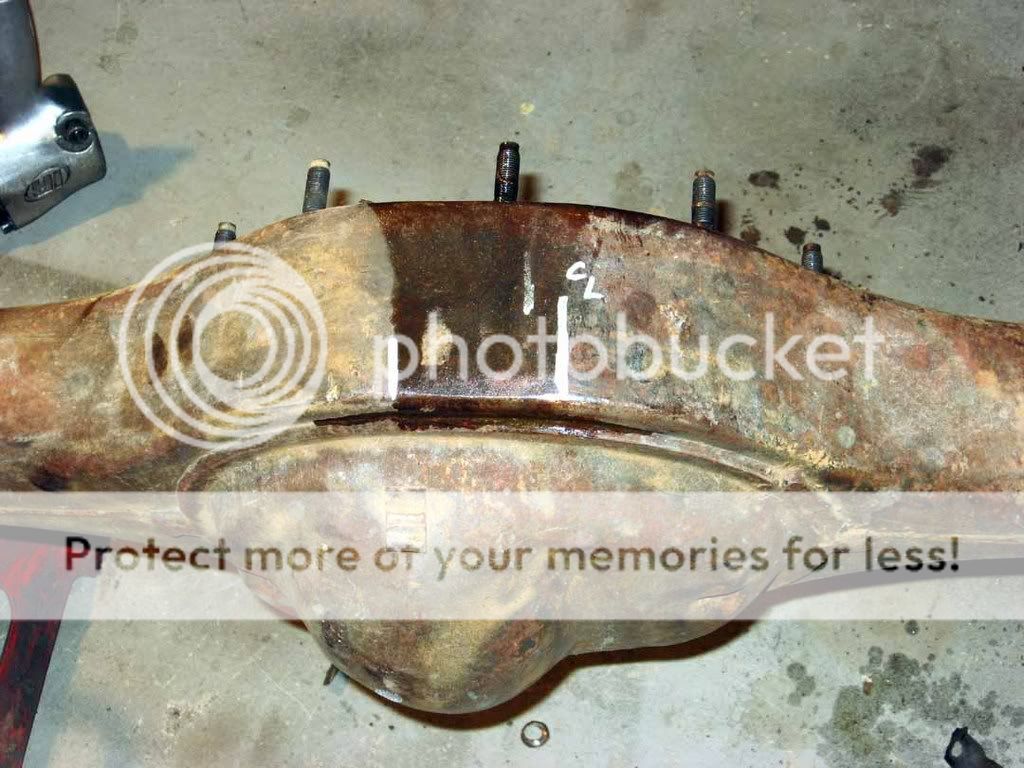

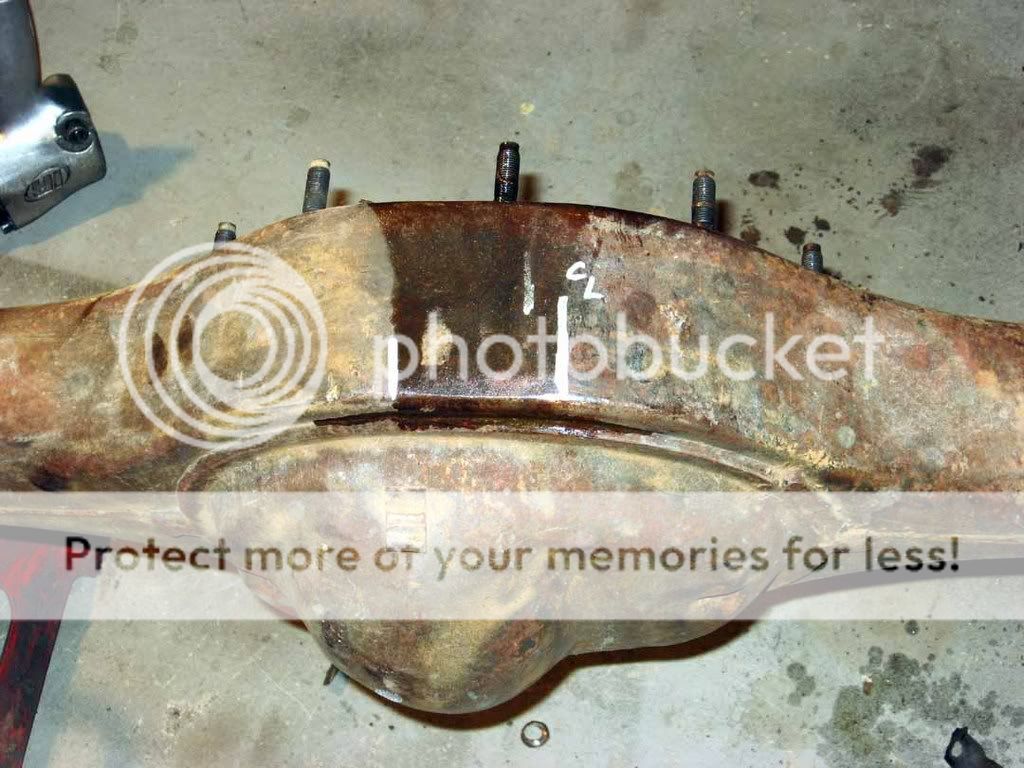

So after the ring gear bolts backed out/ sheared off as well as the ARB blowing up in my Ford 8.8 I decided it was time to build something bigger/stronger like a Ford 9" but it was the wrong width. So that means its time to start cutting!

First determine the axle centerline. Choose a width you want the axle to be. I decided on 61wms to wms to match my front HP44. I also centered the pinion so I cut down 1" on the passenger side and 3" on the driver side. This puts the pinion pretty close to center as well as gave me the desired width. Remember to measure twice cut once!

AARON

First determine the axle centerline. Choose a width you want the axle to be. I decided on 61wms to wms to match my front HP44. I also centered the pinion so I cut down 1" on the passenger side and 3" on the driver side. This puts the pinion pretty close to center as well as gave me the desired width. Remember to measure twice cut once!

AARON