Jeepstah

NAXJA Forum User

- Location

- Central Cali

Hey guys,

Here are some pictures of a project I have been working on to complete my senior mechanical engineering degree. It is your basic spare tire carrier but with the option of two mounting positions for the tire. One will be up high for optimum departure angles off-road and then another position down low to help improve visibility on road. A prototype is in the works but I was wondering what the forum users thoughts are. Part of the project is trying to see what interest their is in the market for a product like this so I figured the best place to get feedback from the off-roading Cherokee market was to go the website that I look at on a daily basis for all my info. Thanks for all your thoughts good or bad.

forum users thoughts are. Part of the project is trying to see what interest their is in the market for a product like this so I figured the best place to get feedback from the off-roading Cherokee market was to go the website that I look at on a daily basis for all my info. Thanks for all your thoughts good or bad.

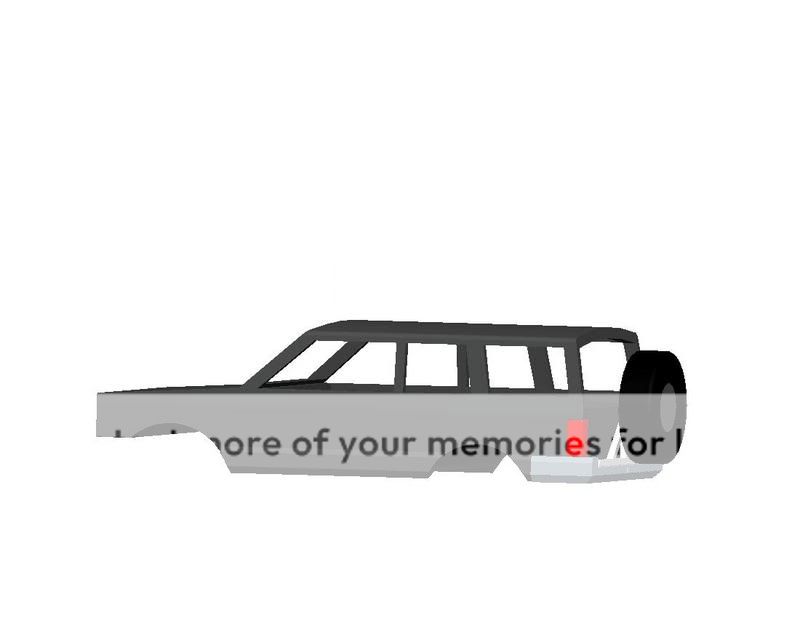

Side shot of the low position and a view out the back window

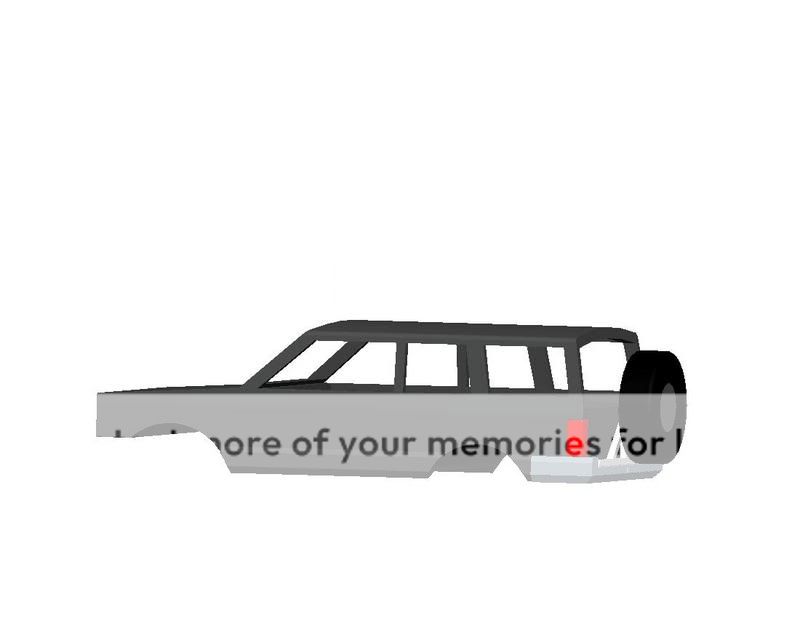

Side shot of the high position

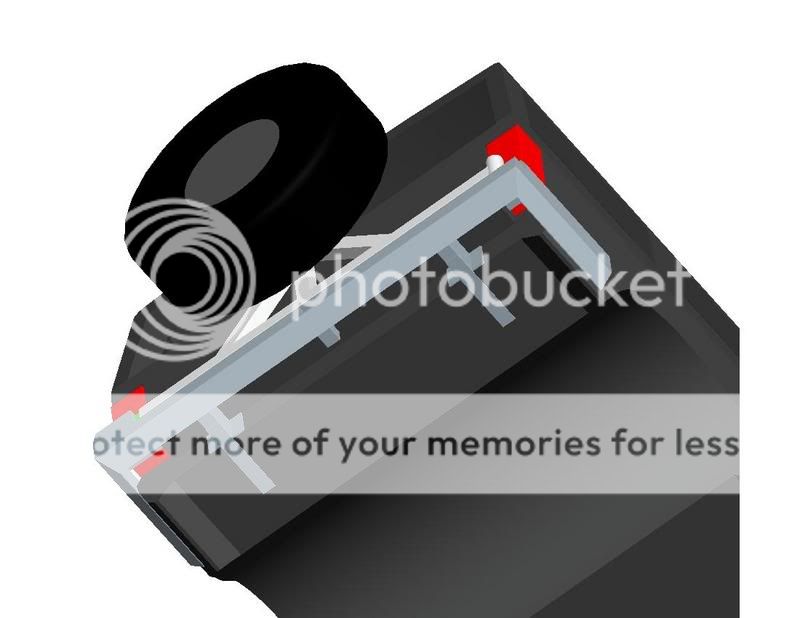

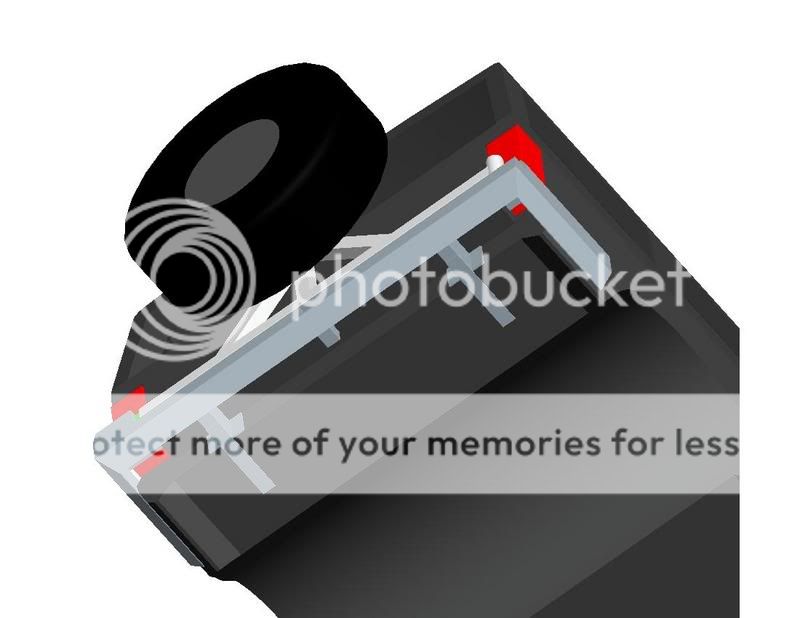

Mounting setup with the stock bolt locations being used as well as a strip down the frame rail much like a hitch would bolt on.

A few shots of it opened

View of the rotary latch setup I would like to use

Full view

The gap where you can see the mounting setup from the top will be covered most likely by some thin metal or plastic just so you can't see through. I also plan to mount some D-ring tabs on the bumper in front of where the mounts weld to the main cross-member. Thanks for looking.

Here are some pictures of a project I have been working on to complete my senior mechanical engineering degree. It is your basic spare tire carrier but with the option of two mounting positions for the tire. One will be up high for optimum departure angles off-road and then another position down low to help improve visibility on road. A prototype is in the works but I was wondering what the

forum users thoughts are. Part of the project is trying to see what interest their is in the market for a product like this so I figured the best place to get feedback from the off-roading Cherokee market was to go the website that I look at on a daily basis for all my info. Thanks for all your thoughts good or bad.

forum users thoughts are. Part of the project is trying to see what interest their is in the market for a product like this so I figured the best place to get feedback from the off-roading Cherokee market was to go the website that I look at on a daily basis for all my info. Thanks for all your thoughts good or bad.

Side shot of the low position and a view out the back window

Side shot of the high position

Mounting setup with the stock bolt locations being used as well as a strip down the frame rail much like a hitch would bolt on.

A few shots of it opened

View of the rotary latch setup I would like to use

Full view

The gap where you can see the mounting setup from the top will be covered most likely by some thin metal or plastic just so you can't see through. I also plan to mount some D-ring tabs on the bumper in front of where the mounts weld to the main cross-member. Thanks for looking.