Got this nov. of 05:

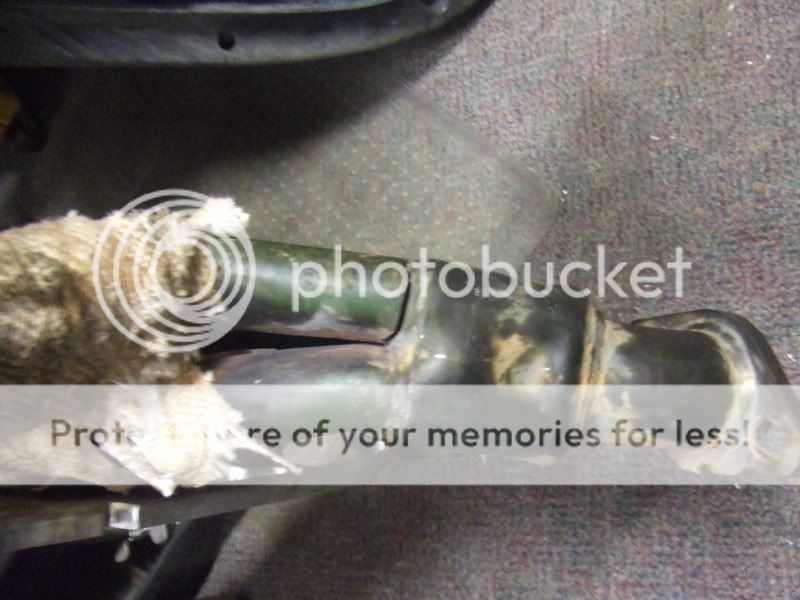

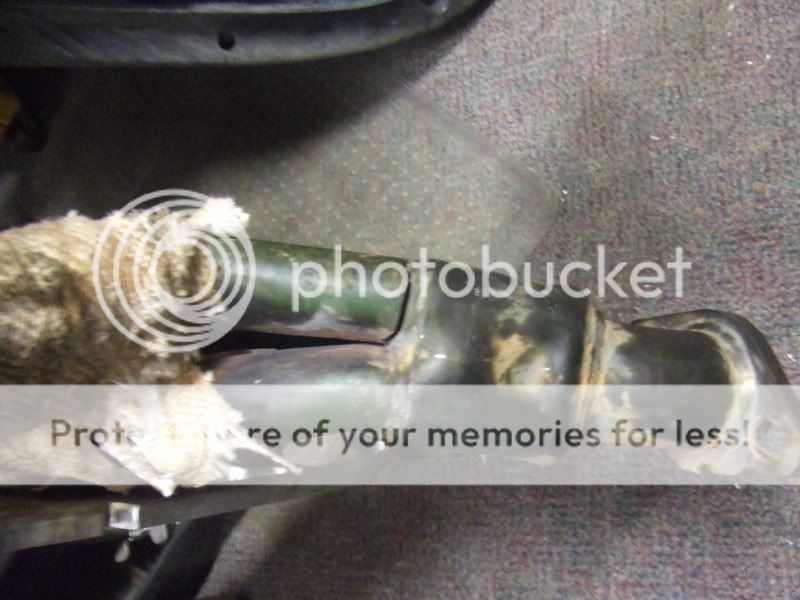

Gibson GP400 - steel material w/ chrome nickel plating. Got it on ebay for close to $300, came w/ warranty and all that jazz. Friend wrapped it up in hdr. wrap, here it is w/ old manifold:

I didn't take an up close pic of the stock manifold's crack, but it's at pretty much the same spot everyone else's is at.

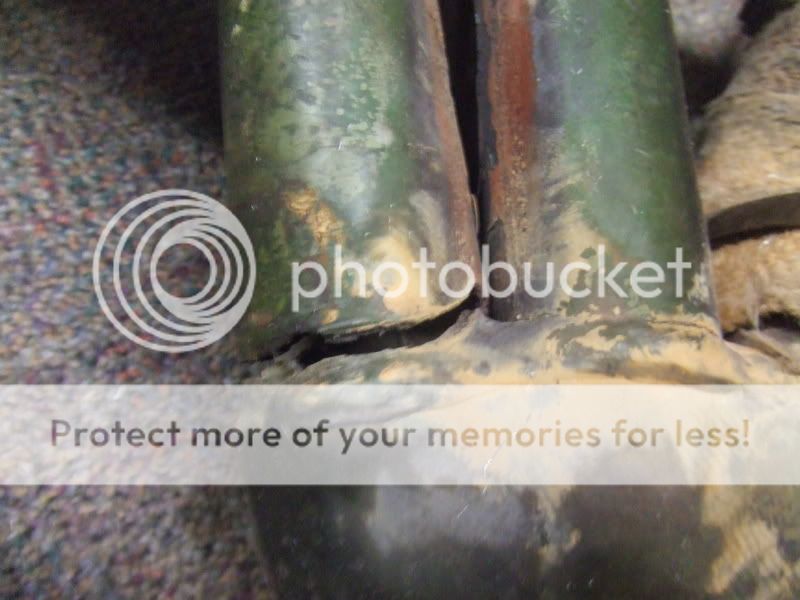

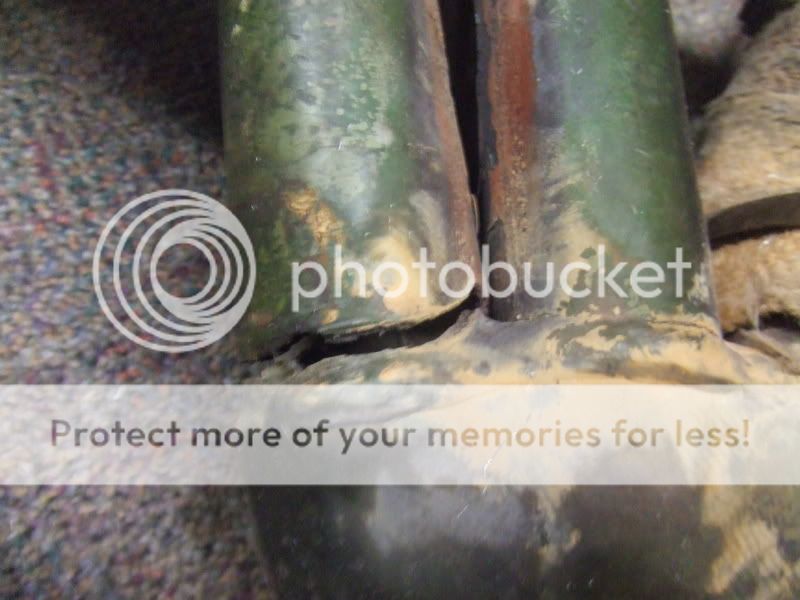

I developed an exaust leak in june of 06, bought the apn manifold couple of months ago and I just haven't gotten around to it. I finally did and when I cut some of the wrapping off, this is what I found:

I thought I just had a hairline crack in the collector pipe.... goes to show I was wrong!!!! The jeep ran way worse w/ the stock manifold crack, it would almost die at idle. I think the hdr. wrap was the only thing keep most of the exhaust flowing... could be wrong.

At first I attributed this to hdr. wrap and inproper torquing (sp?) of bolts (didn't have a torque wrench at the time so we tightened up to what "felt" right, did the re-torque after 100+ miles too). Even w/ those two categories, I believe that is just a defective product. I've actually done less driving the past several months then I did before I got it, so I can't say my driving habits caused this....

I'd like some thoughts on what in the world went wrong w/ this.... I personally think it's funny... but I'm gonna send some pics to gibson... this hdr. maybe has over 15K miles.... I'm not really even mad, just more tired of the whole thing and annoyed.

I posted here as well to get some more tech thoughts on the matter of what could've/did go wrong w/ this and how was my vehicle still running and not throwing codes?!?

If it looks interesting I'll post more pics after I further unwrap and install the apn manifold...

Gibson GP400 - steel material w/ chrome nickel plating. Got it on ebay for close to $300, came w/ warranty and all that jazz. Friend wrapped it up in hdr. wrap, here it is w/ old manifold:

I didn't take an up close pic of the stock manifold's crack, but it's at pretty much the same spot everyone else's is at.

I developed an exaust leak in june of 06, bought the apn manifold couple of months ago and I just haven't gotten around to it. I finally did and when I cut some of the wrapping off, this is what I found:

I thought I just had a hairline crack in the collector pipe.... goes to show I was wrong!!!! The jeep ran way worse w/ the stock manifold crack, it would almost die at idle. I think the hdr. wrap was the only thing keep most of the exhaust flowing... could be wrong.

At first I attributed this to hdr. wrap and inproper torquing (sp?) of bolts (didn't have a torque wrench at the time so we tightened up to what "felt" right, did the re-torque after 100+ miles too). Even w/ those two categories, I believe that is just a defective product. I've actually done less driving the past several months then I did before I got it, so I can't say my driving habits caused this....

I'd like some thoughts on what in the world went wrong w/ this.... I personally think it's funny... but I'm gonna send some pics to gibson... this hdr. maybe has over 15K miles.... I'm not really even mad, just more tired of the whole thing and annoyed.

I posted here as well to get some more tech thoughts on the matter of what could've/did go wrong w/ this and how was my vehicle still running and not throwing codes?!?

If it looks interesting I'll post more pics after I further unwrap and install the apn manifold...