a7273chargerguy

NAXJA Forum User

- Location

- tulsa ok

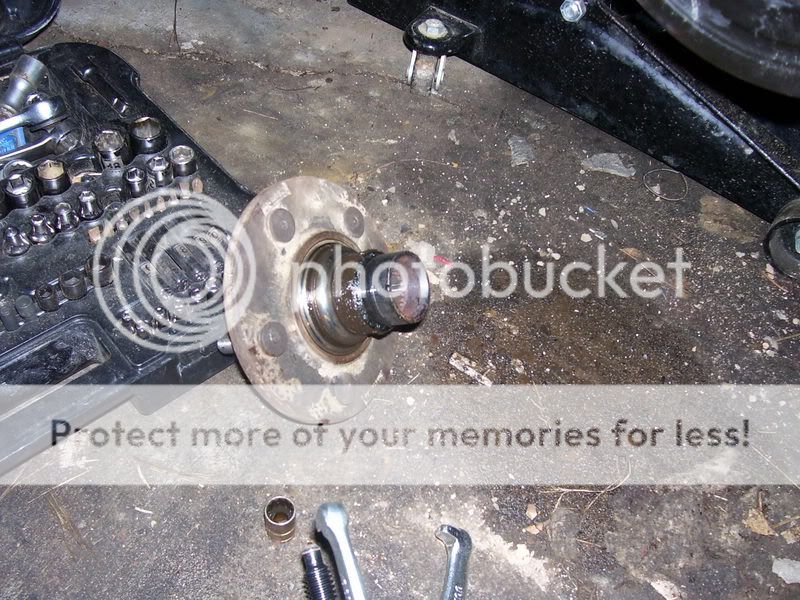

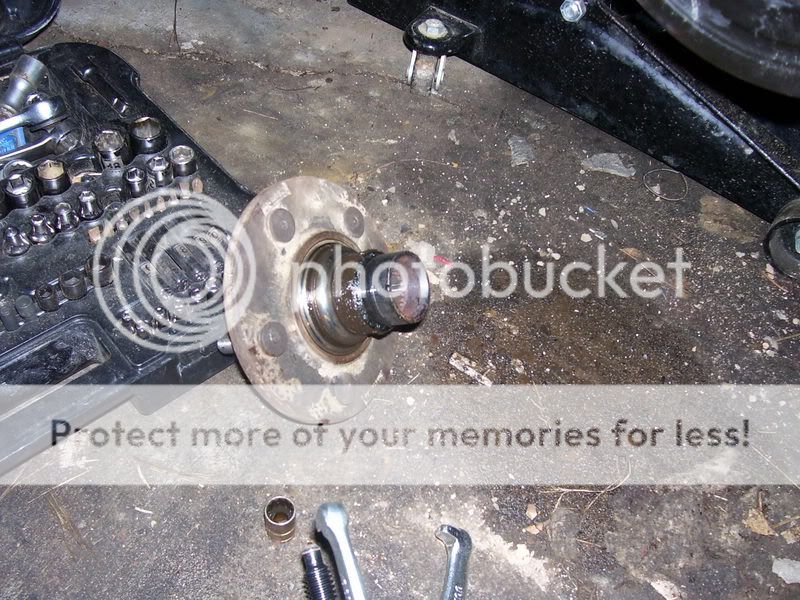

so i am changing the wheel bearings(edit changing hubs) on my 95 cherokee,got the axle nut off(that was a bitch)went and bought a 3 jaw gear puller and took off my bearing,or so i thought.now i have half of it on there still.it is in 4 hi with one tire off the ground.how do i remove the rest of it?it looks like the knuckle is still attached but i removed the three bolts from behind with a 12 point 13mm

Last edited: