KSXJ

NAXJA Forum User

- Location

- Kansas City

My rear bumpstop bolts broke while trying to upgrade them. So instead of welding, since I don't know how, here is what I was thinking.

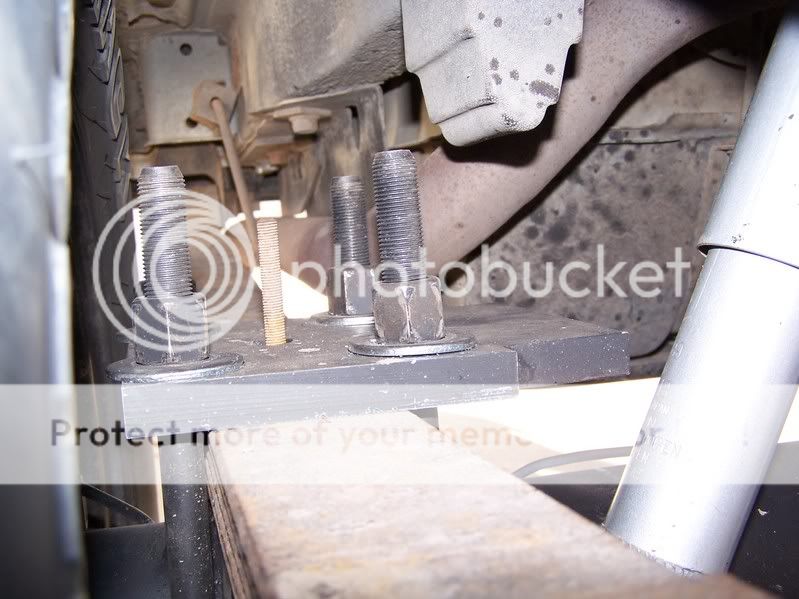

Making a plate like this

But making it bigger so I can attach the bump stop on the side of it(aka - side of the spring) Then putting a plate on the bottom of the unibody that the bump stop would hit. Basically reversing the way the bumpstops work.

any ideas, comments, suggestions????

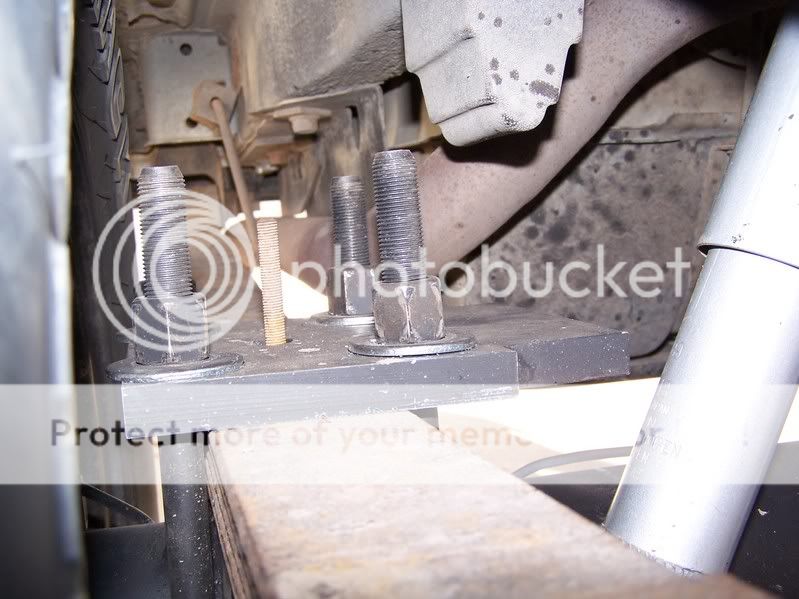

Making a plate like this

But making it bigger so I can attach the bump stop on the side of it(aka - side of the spring) Then putting a plate on the bottom of the unibody that the bump stop would hit. Basically reversing the way the bumpstops work.

any ideas, comments, suggestions????