Jerms

NAXJA Forum User

- Location

- Northern utah

well let me start off with the specs so you'll have an idea what i've got.

88' xj limited 4.0 auto

custom longarm/radius arm front supsension, around 8" of lift

Dana 44 front axle out 78 F-250 full width,

custom draglink and trackbar, that uses the rock krawler frame mount.

Drop pitman arm,

36" swamppers

Here is my delima,

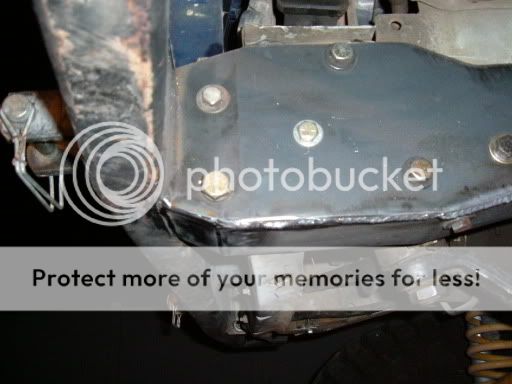

The frame where the steering gear bolts to cracked badly, the bottom 2 bolts have nearly pulled through the frame on the out side. The botom of the frame "rail" is cracked from the oustide of the forward most steering gear bolt to the other side of the frame. and the frame now appears to be about 3/4" wider than it used to be on the bottom.

What i have done so far,

I bought some 3/16"plate steel, and drilled the holes to match the steering gear pattern, i put one plate on both sides of the frame and squished the frame back to the width it was suposed to be and welded the frame crack along the botom of the rail back together. Then i removed the plates welded all the cracks that i could find, then put plates back on and welded the outside plate to the frame. i don't intend to weld the inner plate it is there to aid in support.

now that i think i'm done when i steer there is still some frame flex at the bottom two bolts i would say it is minnor (about 1/8" at the most) but there is still some twisting, should i be concered and do further reinforcing or is some felxing acceptable?

Future Plans,

hydraulic assist ram and steering gear brace. will be completed before any serious wheeling.

also while i was in the middle of all of this i rebulit the steering gear, while i was in the process of the bleeding the system the pitman arm shaft seals blew out and are now sitting on top of the pitman arm. can anybody tell me what i did wrong? it was working and i was about to go for a drive when it happened i had put the weight on the front wheels and was doing a few more lock to lock turns to help bleed and it blew right as it hit lock on right turn.

thanks in advance.

Jerm S.

88' xj limited 4.0 auto

custom longarm/radius arm front supsension, around 8" of lift

Dana 44 front axle out 78 F-250 full width,

custom draglink and trackbar, that uses the rock krawler frame mount.

Drop pitman arm,

36" swamppers

Here is my delima,

The frame where the steering gear bolts to cracked badly, the bottom 2 bolts have nearly pulled through the frame on the out side. The botom of the frame "rail" is cracked from the oustide of the forward most steering gear bolt to the other side of the frame. and the frame now appears to be about 3/4" wider than it used to be on the bottom.

What i have done so far,

I bought some 3/16"plate steel, and drilled the holes to match the steering gear pattern, i put one plate on both sides of the frame and squished the frame back to the width it was suposed to be and welded the frame crack along the botom of the rail back together. Then i removed the plates welded all the cracks that i could find, then put plates back on and welded the outside plate to the frame. i don't intend to weld the inner plate it is there to aid in support.

now that i think i'm done when i steer there is still some frame flex at the bottom two bolts i would say it is minnor (about 1/8" at the most) but there is still some twisting, should i be concered and do further reinforcing or is some felxing acceptable?

Future Plans,

hydraulic assist ram and steering gear brace. will be completed before any serious wheeling.

also while i was in the middle of all of this i rebulit the steering gear, while i was in the process of the bleeding the system the pitman arm shaft seals blew out and are now sitting on top of the pitman arm. can anybody tell me what i did wrong? it was working and i was about to go for a drive when it happened i had put the weight on the front wheels and was doing a few more lock to lock turns to help bleed and it blew right as it hit lock on right turn.

thanks in advance.

Jerm S.