Incredible Hulk

NAXJA Forum User

- Location

- Burnsville, Minnesota

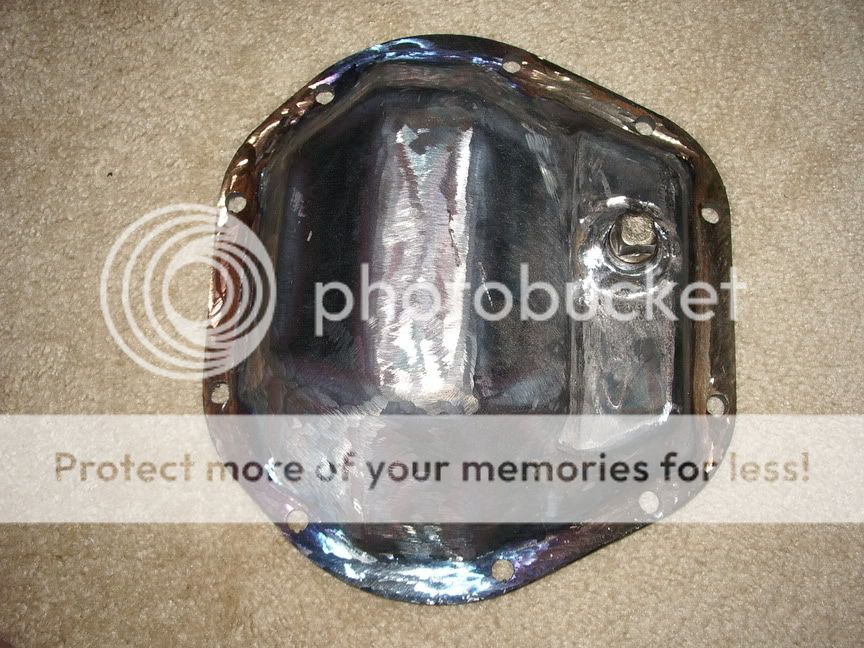

Well, I finally finished half of one of my projects. Here is a pic of my new diff protection. This one is for the front 44, hence the portion on the top inside edge ground out to clear my RE bracket. The rear will get the same treatment. Made from one of the rings provided by a fella on pirate, and a bunch of 1/4" stuff. Should be much more beefy than my warn guard I have on there now.

This one was a learning experience for many reasons. I mounted it all WAY too close to teh diff, so when it moved around during welding- I ended up having to grind a lot out of the inside edges to get it to fit! Should be good now though- heres hopin at least! Anyways, the rear one should be easier!

Many other projects to follow....

j

This one was a learning experience for many reasons. I mounted it all WAY too close to teh diff, so when it moved around during welding- I ended up having to grind a lot out of the inside edges to get it to fit! Should be good now though- heres hopin at least! Anyways, the rear one should be easier!

Many other projects to follow....

j