Timmay

NAXJA Forum User

- Location

- Marlton, NJ

My buddy from Philly (Colin) was expected to come over at 1pm to get started on setting up his 8.8 for his ZJ. In the meantime I installed my YJ front lines to give me some extra droop room.

Comparison Pic... about 3" longer than the stock line.

Old line, relocated down farther.

New line, also in the relocated spot.

Semi Closeup.

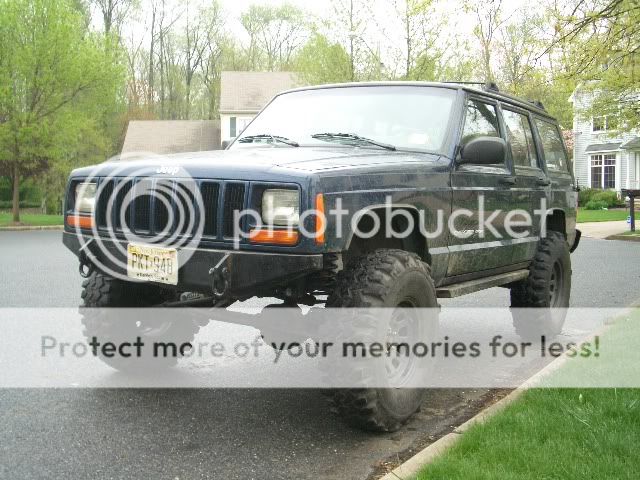

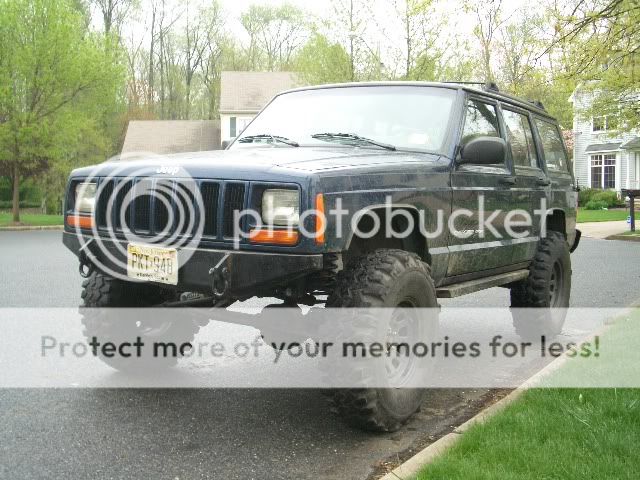

Here's what I was waiting for. Colin brought me his 34" LTBs to use until his ZJ was trail ready in exchange for welding all his mounts on the 8.8.

Me and Deke with Colin parked in the driveway ready to get started on the 8.8.

Workin through the rainy night...

This is where I got to tonight. I pulled the shafts and backing plates to make sure I can get the MIG gun in there to get a nice weld.

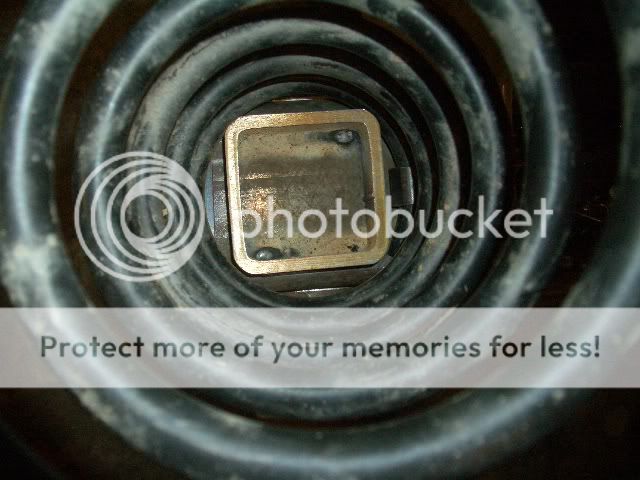

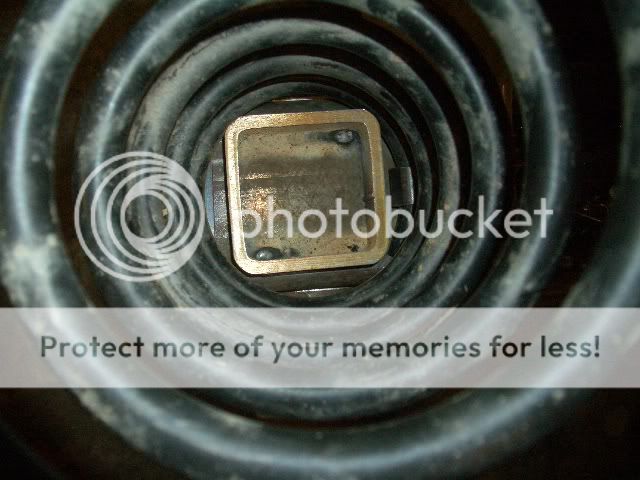

The fairly ghetto coil pads. The 1/2" plate is just to support the coil so it sits even. The 3x3 tube centers the coil and the small peice of 3/4" tube is the retainer.

That's all the pics I took. I figured i'd post an update on our progress. Colin is thinking by later May he will be ready to wheel. Throughout this week we will be tacking various pieces onto the axle and i'm going to sandblast and finish weld it at school. Should turn out real well. :wave:

Comparison Pic... about 3" longer than the stock line.

Old line, relocated down farther.

New line, also in the relocated spot.

Semi Closeup.

Here's what I was waiting for. Colin brought me his 34" LTBs to use until his ZJ was trail ready in exchange for welding all his mounts on the 8.8.

Me and Deke with Colin parked in the driveway ready to get started on the 8.8.

Workin through the rainy night...

This is where I got to tonight. I pulled the shafts and backing plates to make sure I can get the MIG gun in there to get a nice weld.

The fairly ghetto coil pads. The 1/2" plate is just to support the coil so it sits even. The 3x3 tube centers the coil and the small peice of 3/4" tube is the retainer.

That's all the pics I took. I figured i'd post an update on our progress. Colin is thinking by later May he will be ready to wheel. Throughout this week we will be tacking various pieces onto the axle and i'm going to sandblast and finish weld it at school. Should turn out real well. :wave: