againstherwill

NAXJA Forum User

- Location

- Indianapolis

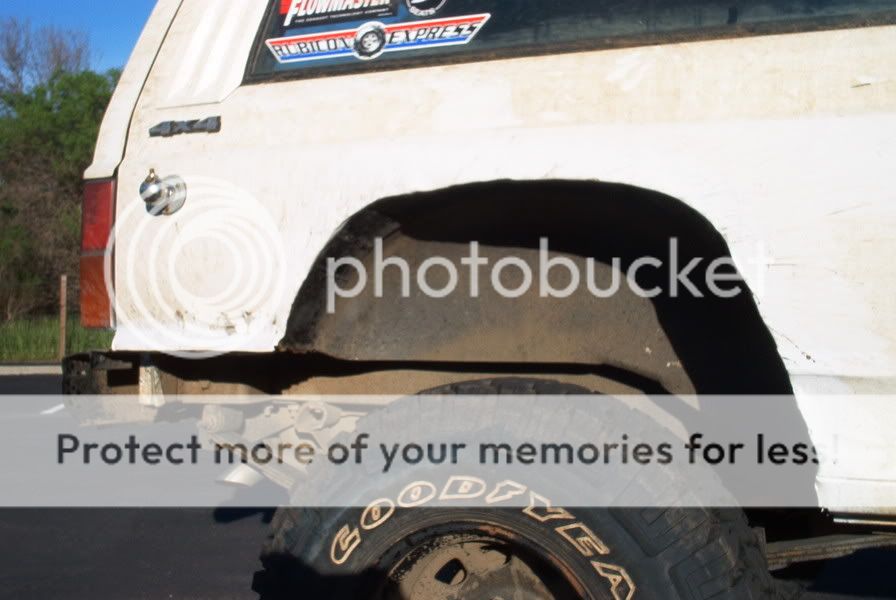

So I my dad is bringing me a welder to use for a while. And a cutting wheel. We are going to do some cutting this weekend WOOHOO. We are going to mark where the flares are now and cut there. In the back we are only going to cut the outside fenderwall and then cut the innerwall to size and weld it back together.

So what you say. Lots of people have done this.

My question is this. this cut seems to take 4" off. what it the biggest tire you think I can get in there at stock height with 4"BS wheels? I am going for a LOC wheeler with lift to come later. I only what to cut once. Will this fit 32's at stock or do I have to trim more?

Oh, btw it is a 89 laredo with new stock spings front and back

Thanx

So what you say. Lots of people have done this.

My question is this. this cut seems to take 4" off. what it the biggest tire you think I can get in there at stock height with 4"BS wheels? I am going for a LOC wheeler with lift to come later. I only what to cut once. Will this fit 32's at stock or do I have to trim more?

Oh, btw it is a 89 laredo with new stock spings front and back

Thanx

Last edited: