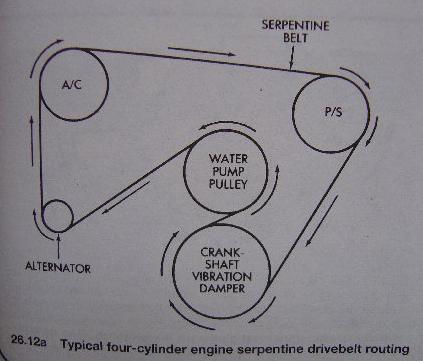

I am getting ready to install an electric fan and I am wondering if anyone besides gojeep has completly removed the pully and rerouted the belt. I am thinking of doing so, so I can put in a larger 14in fan. Either a perma-cool or a zirgo and they have 3.5 inch depths. I only have a 3 inch depth so if I completly remove the pully I will have no problems. Here is very poor pic of how I am thinking of routing it (almost like the 4 cyl belt routing) What do you guys think?

I am pretty sure because I change the routing the original belt would fit to. Let me know what you think.

Thanks

Chris

I am pretty sure because I change the routing the original belt would fit to. Let me know what you think.

Thanks

Chris