BrianJr

NAXJA Forum User

- Location

- Blacksburg Virginia

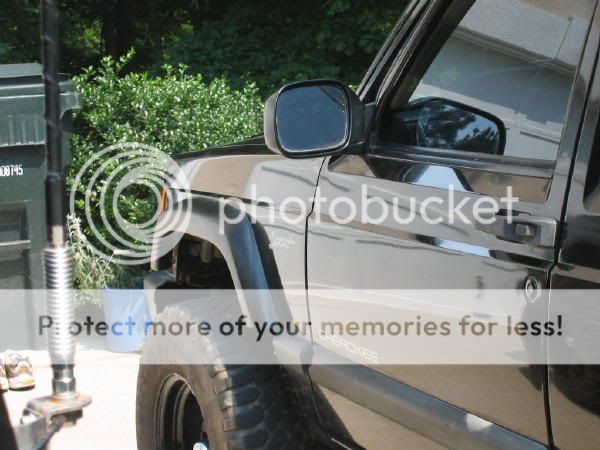

I have been running flareless for a few months and don't like it. So I was looking at ways to add flares again. As I have the stock flares I've been considering how to use those.

I had trimmed away the holes for the original brackets. I talked with a guy at a body shop and he suggested using 3M trim adhessive to attach the flares. I didn't think it would work but after a few weeks with one of the flares glued on as a test it looks like it will. Have any of you used this stuff to hold flares on for any length of time?

The stock flares are quite a bit above the seam that runs around the wheel wells. It seems that I could trim a lot more metal if I ran this type of setup. So it looks like I could get rid of some bumpstop height too. I am not eager to cut my fenders above the seam for the flares without knowing if anyone else has used this 3M adhessive successfully.

Anyway, just curious if anyone here had tried this

Thanks,

-Brian

I had trimmed away the holes for the original brackets. I talked with a guy at a body shop and he suggested using 3M trim adhessive to attach the flares. I didn't think it would work but after a few weeks with one of the flares glued on as a test it looks like it will. Have any of you used this stuff to hold flares on for any length of time?

The stock flares are quite a bit above the seam that runs around the wheel wells. It seems that I could trim a lot more metal if I ran this type of setup. So it looks like I could get rid of some bumpstop height too. I am not eager to cut my fenders above the seam for the flares without knowing if anyone else has used this 3M adhessive successfully.

Anyway, just curious if anyone here had tried this

Thanks,

-Brian