shizza-my-nizza

NAXJA Member #671

- Location

- Westminster, MD

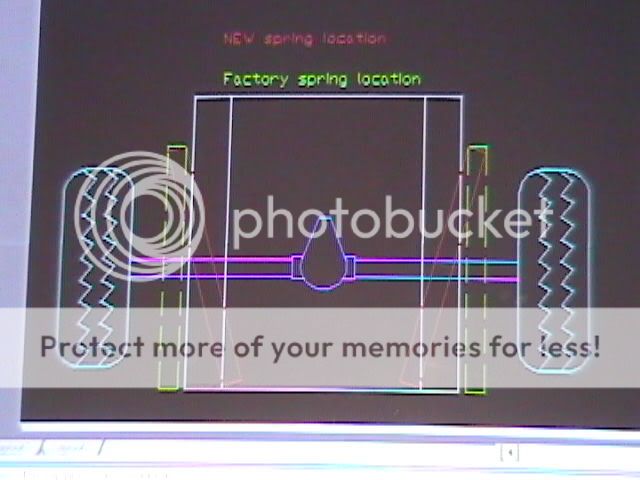

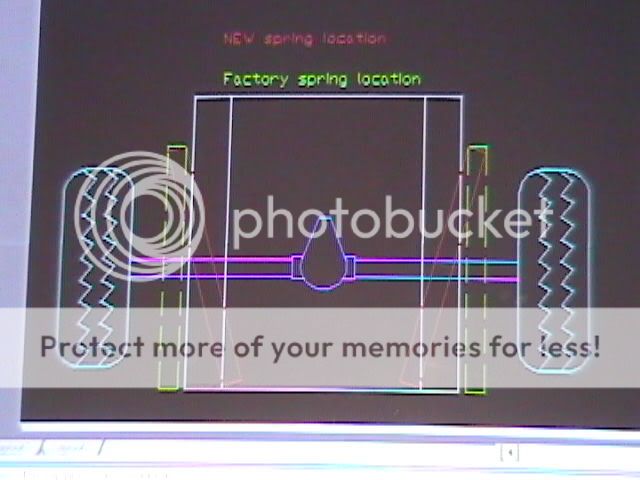

I like the idea of getting more articulation by mounting the rear leafs farther inboard but I don't like the idea of the loss of stability that is associated with doing so. So I was wondering if you guys think would happen if the rear leafs were mounted with rear eyes inboard and the front eyes in aprox the stock location. Do you think a system like this could give me more flex in the rear suspention with less loss of stability?

or am I just asking for trouble?

or am I just asking for trouble?