hot_rod_hooligans

NAXJA Forum User

- Location

- Indianapolis

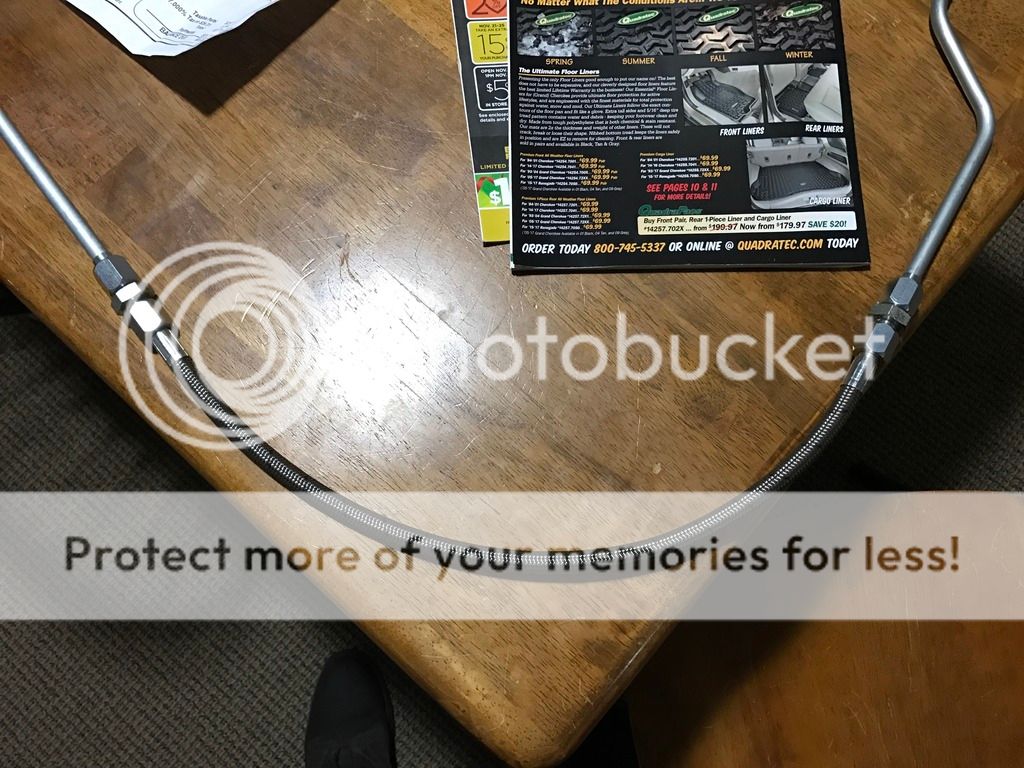

So I had to replace the upper trans cooler line when I replaced the water pump this weekend, it kinked when I tried to remove it from the radiator, replaced with new Dorman lines. On the way to work yesterday(about half way/45 min from work/home), the quick connect right by the harmonic balancer failed and dumped my transmission fluid all over the road. Hauled it back to my house, replaced the line again, started it up, and immediately started dumping tranny fluid from the same, new connection(both male and female lines of the connection are new). Now I'm done with trying Dorman, I'm thinking either Mopar replacement or going down by the Speedway and having a braided stainless line made up. Anyone have any other options? I'm perfectly fine replacing with one line from trans to radiator instead of one with the quick connect, just eliminates a potential leak in the future.