91Heep

NAXJA Forum User

- Location

- North Louisiana

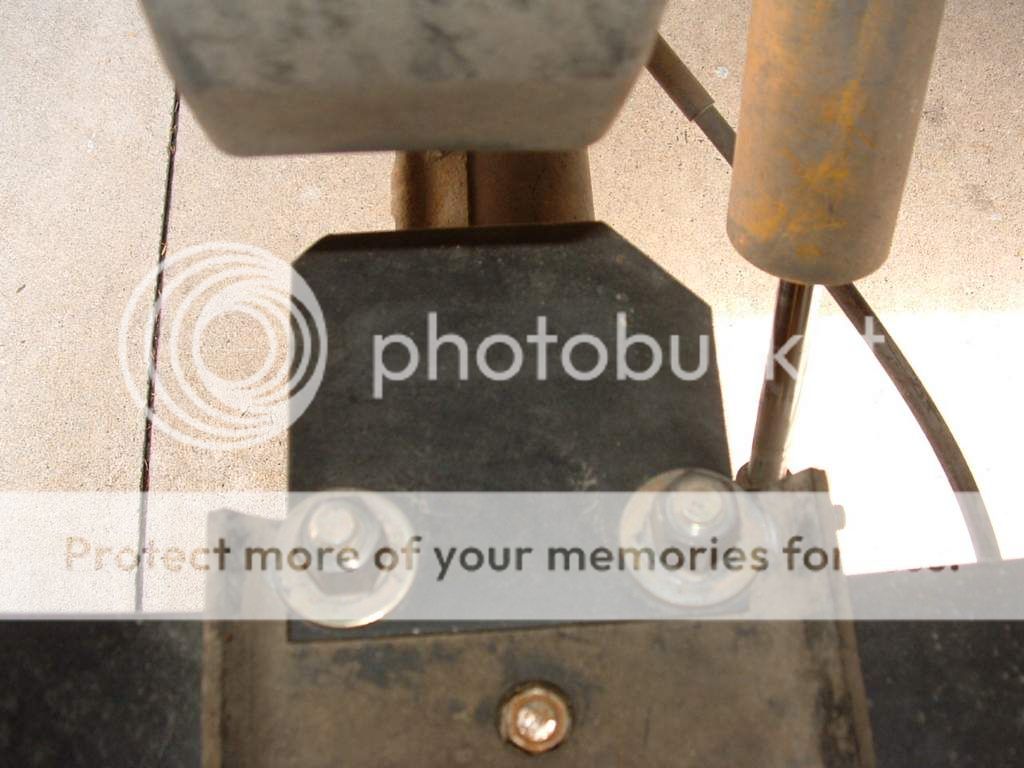

I'm thinking about using a set of the spring plates offered that have a spot for the bump stop to be mounted or for it to make contact.

Are there any issues with over stressing the u bolts or any other known failures while using them.

My setup will be 4" lift with shackle relocators and 33" tires.

91 2 door.

Are there any issues with over stressing the u bolts or any other known failures while using them.

My setup will be 4" lift with shackle relocators and 33" tires.

91 2 door.