jeepfreak1020

NAXJA Forum User

- Location

- Thornton

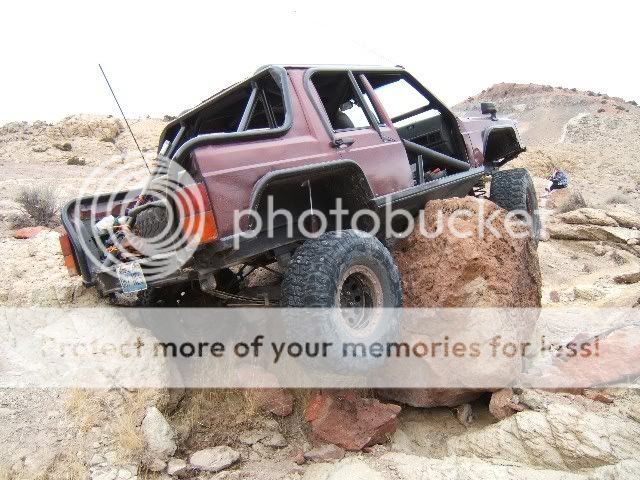

Never really done a build thread before but a few people have asked me to so figured I would. Second Cherokee I have owned and this will be phase three for this one. Picked it up back in December 2012 bone stock from a older couple who only used it to go grocery shopping. Had never seen a dirt road before. Bad ball joints, destroyed tires and death wobble like no other. Started collecting parts to build a 44/9 combo on 37s and stretched to 105. It wheeled awesome and kept adding parts, cromo shafts, beadlocks blah blah all that good stuff. Decided It was time to build tons and join that group, but wanted something different than every other Cherokee on tons and 40s chopped up, but wanted to see what kind of budget I could keep it under. So my budget was 5k not including wheels and tires. Sourced a king pin 60, geared to 5.38 and used a old Spartan locker we had laying around my shop, trussed it and used a crane cover. I knew I needed to address the knuckles, since the factory knuckles are weak, so I decided to plate them and call it a day. Picked up crane high steer arms, Yukon 35 spline stubs and warn slugs we had laying around. 14 got 5.38 and what I call the orb of traction. The plan was 4 link front and rear with 2" 7075 aluminum links and full hydro. But I wanted everything behind the axle, so single ended ram and a tie rod it was. A double 231/300 combo was to be used. I'll let the pictures do more talking! Hope you guys all enjoy!

[/[URL=http://s162.photobucket.com/user/Jeepfreak1020/media/4BD9FC22-3436-48B7-8AE1-4B07336FECB6_zpszk67yuio.jpg.html]

[/[URL=http://s162.photobucket.com/user/Jeepfreak1020/media/4BD9FC22-3436-48B7-8AE1-4B07336FECB6_zpszk67yuio.jpg.html]

[/[URL=http://s162.photobucket.com/user/Jeepfreak1020/media/4BD9FC22-3436-48B7-8AE1-4B07336FECB6_zpszk67yuio.jpg.html]

[/[URL=http://s162.photobucket.com/user/Jeepfreak1020/media/4BD9FC22-3436-48B7-8AE1-4B07336FECB6_zpszk67yuio.jpg.html]