Hello everyone I need help from anyone with XJ experience. Here is my story: 300K miles on her, My distributor shaft bearings went and she left me having to get towed. I replaced the distributor with a new one and set it at TDC. She was off by a tooth but it was set correctly. my check engine light comes on and the code reader states crank sensor error. I replaced the crank sensor but the same error continues. I took it to a mechanic who is a chrysler tech"yeah right". He states I have a short in my ignition harness and my ECM is going. Ok I get a short specialist to look into the problem 300$ later its your plugs to your ECM. Replace your ignition harness. Could'nt find one I found one for a 98 in kansas ok I had to swap all the plugs for everything. And At the same time I figured let me install a remanufactured ECM, And all my sensors IAC, TPS, crank, speed, temp ect. my check engine light continues and the crank sensor error still the same. She starts every now and then with a miss resulting in me having to restart her again with the miss disapearing and she idles fine. As I drive she has a few sputters as I reach 55 and 60. But they go away. when I stop and turn her off and go about my business and I return to start her to leave she cranks and cranks And I have to press on the gas pedal for her to restart. My fuel pressure is fine my fuel pump is fine also. What can be my problem she runs good still can anyone give me some advice. I'm begging you please!!!!!!

-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1997 Xj Help

- Thread starter clark40

- Start date

mcnamaag

NAXJA Forum User

- Location

- Red Lion, PA

If you haven't already pull you distributor and clock it back one tooth. I have a feeling that's your issue.

Runnin'OnEmpty

NAXJA Forum User

- Location

- Southeast USA

I believe the distributor is set 360 engine degrees off, meaning the TDC was set while on the exhaust stroke instead of the compression stroke.

If true, this might account for the erratic running upon

subsequent startups.

It's easy to check. Just turn the engine by hand to confirm

TDC on compression, and observe where the rotor is

pointing. It should be pointing just to the side of the

number one terminal on the cap.

If true, this might account for the erratic running upon

subsequent startups.

It's easy to check. Just turn the engine by hand to confirm

TDC on compression, and observe where the rotor is

pointing. It should be pointing just to the side of the

number one terminal on the cap.

ok the last mechanic set it according to him correctly. He gave up because he said he can't figure out the constant crank sensor errors. When she is cold she starts right up. but when she's hot while trying to start her she cranks and cranks until I step on the gas then she starts. BUT!!! some times she starts up with a tremble and you can feel the miss while holding your hand on the rear exhaust. So I then have to shut her down and restart her and she runs so normal. I've had 3 mechanics set the distributor and I'm still not satisfied. I know if I took my truck to jeep they would some how come up with various ways to rob me blind. You good folks may dissagree with me but dealerships are crooks!!! I was thinking maybe there is a way to synchronize all the sensors with the ECM? :gee:

- Location

- Minneapolis, MN

......thinking maybe there is a way to synchronize all the sensors with the ECM?

The DRB-III Scan Tool is used to sync the Distributor to fine tune the timing. The Dealership and some larger independent repair shops have one.

TDC is usually close enough, but it seems in your case, close enough really isn't.

CharlesS

NAXJA Forum User

- Location

- Quezon Province, Philippines

This may be a stupid question, but when the distributor is installed you are supposed to put an alignment tool (I use a toothpick) thru a hole in the plate where the CPS attaches then thru the distributor housing to ensure they are synchronized properly and then align the slot on the distributor shaft with the oil pump drive. This is all assuming the engine is at TDC.

I have swapped out several Jeep distributors over the years and this is the process I use. Also make sure you install a new gasket between the distributor mount and the engine block to sure no oil leakage.

I have swapped out several Jeep distributors over the years and this is the process I use. Also make sure you install a new gasket between the distributor mount and the engine block to sure no oil leakage.

Yes & sometimes you'll get a 4.0L distributor with a 2.5L drive gear so you have to drive out the roll pin holding the gear on and swap on your old drive gear. There are no bearings in the distributor, just two metal bushings. While the 2.5L/4.0L drive gears "look" the same, they are offset differently so you will never get a 2.5L drive gear to line up properly on a 4.0L.

Yes this is where I'm leaning towards:idea:The DRB-III Scan Tool is used to sync the Distributor to fine tune the timing. The Dealership and some larger independent repair shops have one.

TDC is usually close enough, but it seems in your case, close enough really isn't.

I said bearings out of gest. But when my distributor shaft went I took the cap off and the rotor was in pieces. The shaft itself moved north and south while in place. :gee:Yes & sometimes you'll get a 4.0L distributor with a 2.5L drive gear so you have to drive out the roll pin holding the gear on and swap on your old drive gear. There are no bearings in the distributor, just two metal bushings. While the 2.5L/4.0L drive gears "look" the same, they are offset differently so you will never get a 2.5L drive gear to line up properly on a 4.0L.

your right but I was towed off the highway to a local parking lot. I returned the next day in a panic because I faced being towed again at my expence due to town ordinances. The police kept coming by to make sure I was going to get my vehicle out that same day. So I did what I could intalling the new distributor and got her started and I manage to get home. It's been downhill ever since. thanks:gee:This may be a stupid question, but when the distributor is installed you are supposed to put an alignment tool (I use a toothpick) thru a hole in the plate where the CPS attaches then thru the distributor housing to ensure they are synchronized properly and then align the slot on the distributor shaft with the oil pump drive. This is all assuming the engine is at TDC.

I have swapped out several Jeep distributors over the years and this is the process I use. Also make sure you install a new gasket between the distributor mount and the engine block to sure no oil leakage.

mcnamaag

NAXJA Forum User

- Location

- Red Lion, PA

CharlesS hit the nail on the head. Close enough isn't good enough. Try his suggestion.

CharlesS hit the nail on the head. Close enough isn't good enough. Try his suggestion.

I would give the suggestion from Charles & I a shot before you take it to the dealer.

I'll 3rd that. It is easy to be a tooth advanced or retarded.

Sidewinder CC

NAXJA Forum User

- Location

- Canton, Michigan

I said bearings out of gest. But when my distributor shaft went I took the cap off and the rotor was in pieces. The shaft itself moved north and south while in place. :gee:

My guess is that if the rotor was that damaged from the distributor shaft movement that the Camshaft Position Sensor may have been damaged as well. And if you reused this Cam Sensor when you replaced the distributor it may be the root cause of your problem.

~~~~~~~

You can check the distributor timing relatively easily by doing the following:

Remove the radiator electric fan so you can get a direct view of the crankshaft damper timing slot on it.

Remove the distributor cap, rotor, and Cam Sensor.

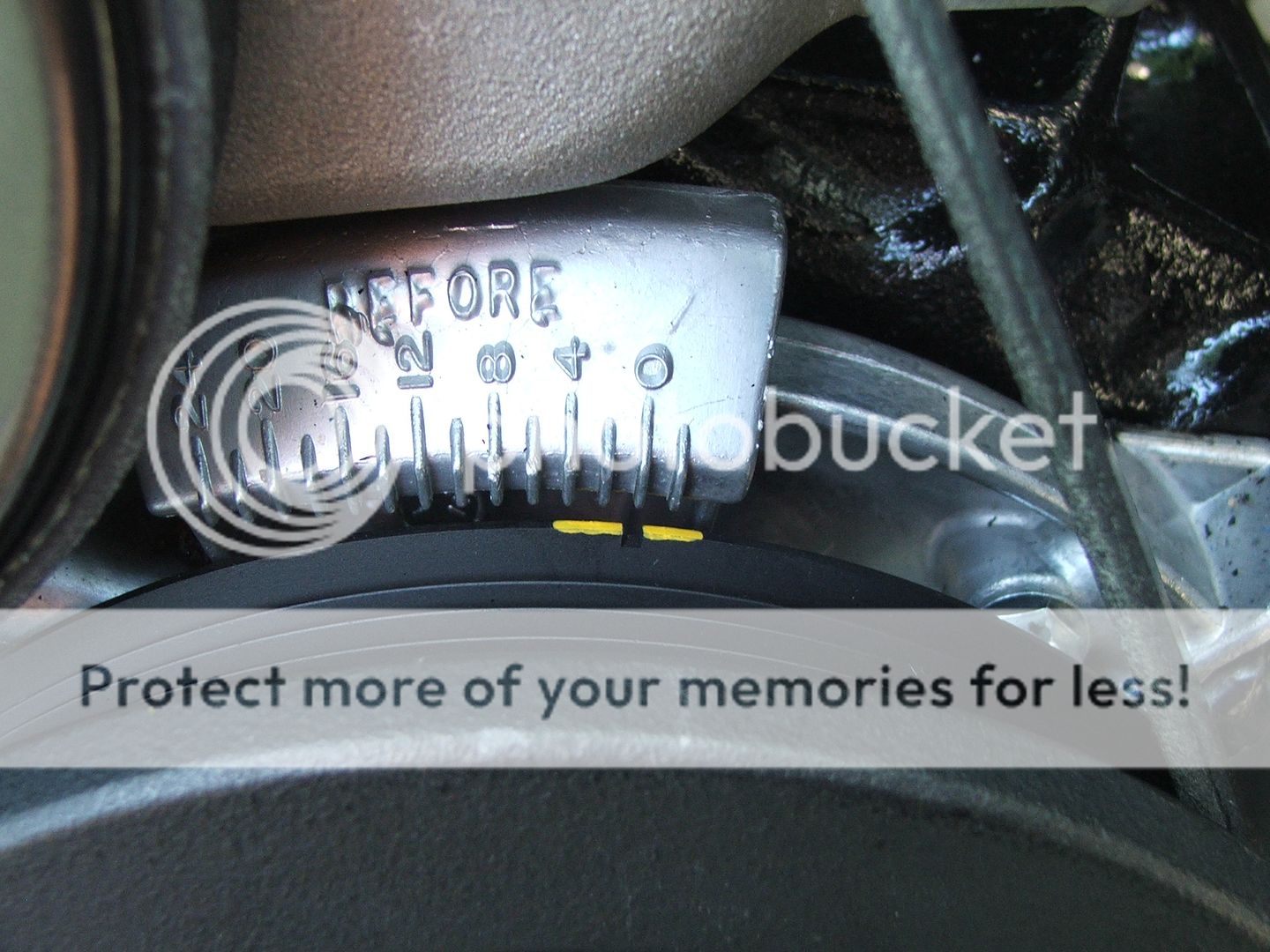

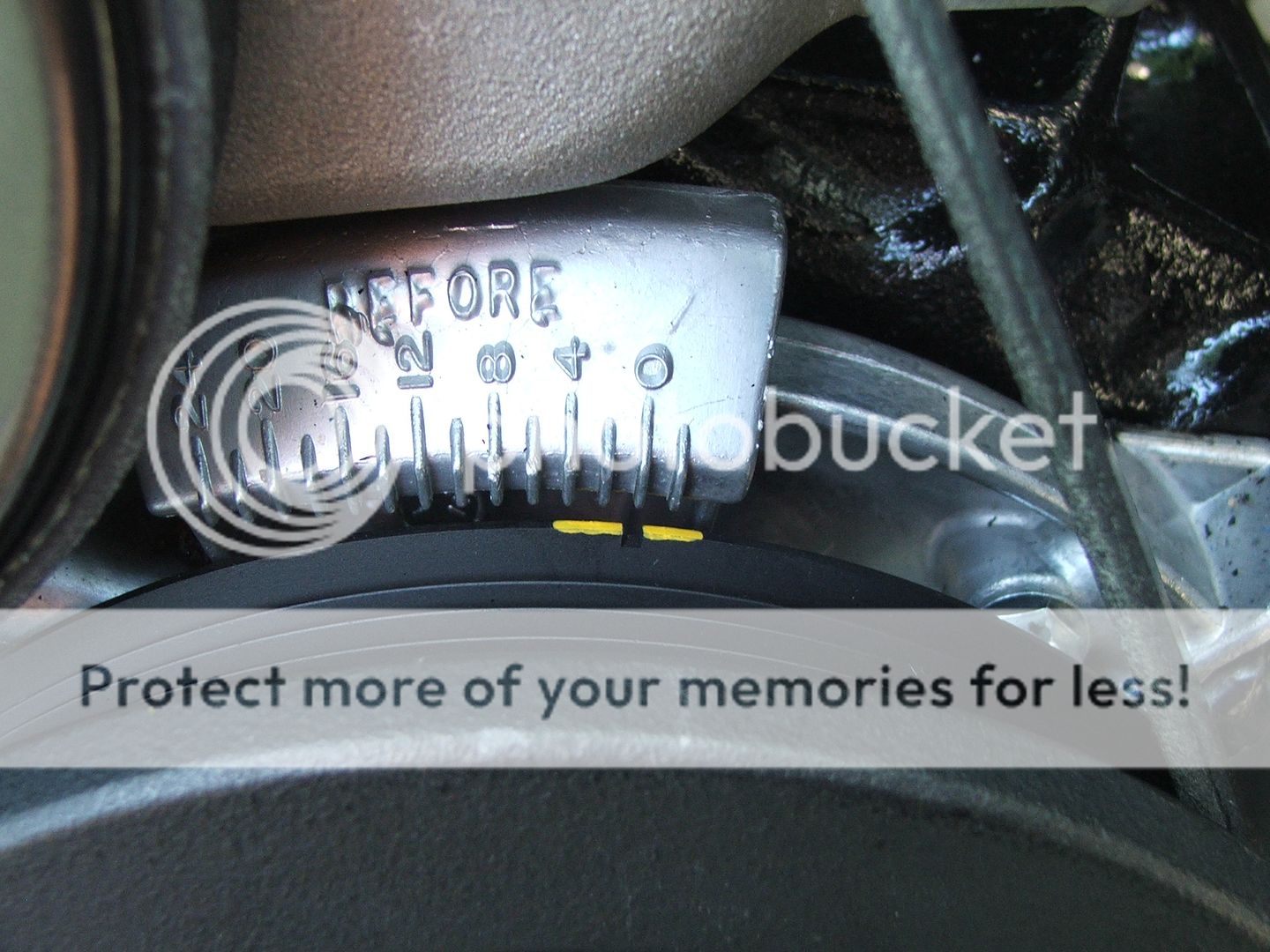

Rotate the crank damper in a clockwise direction until the timing slot on the damper aligns with the zero (0) timing mark on the timing chain cover timing mark. See pic.

Reinstall the rotor only.

The rotor should be pointing just past the #1 spark plug terminal Not the #6 terminal. See pic.

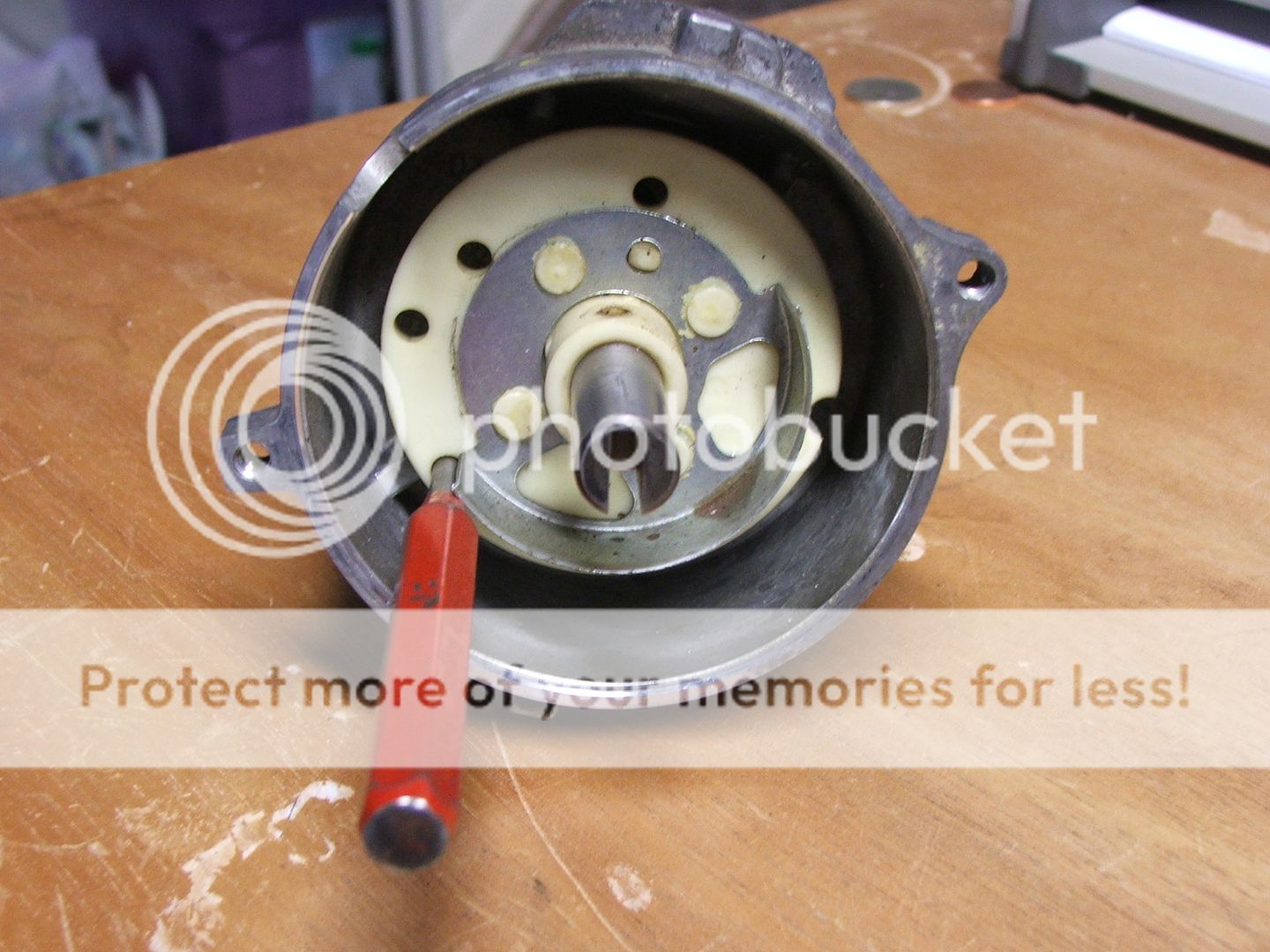

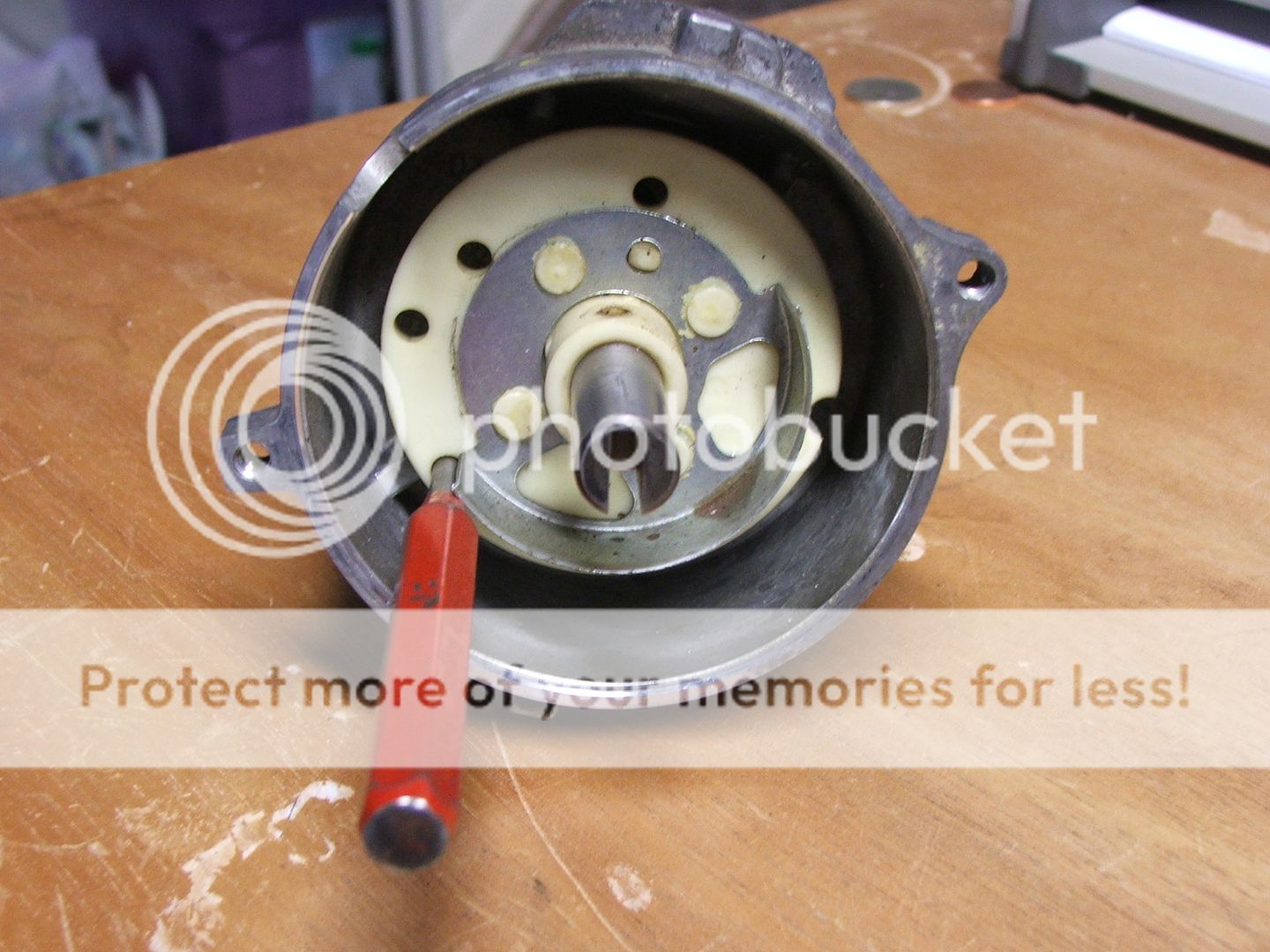

Using a 3/16" pin punch or drill bit, you should be able to insert the punch through the alignment hole in the plastic ring in the distributor and down thru the alignment hole in the distributor base. If it won't pass thru the hole in the distributor base the distributor is improperly installed. See pics.

Timing marks:

Pin punch installed in plastic ring:

Pin punch installed (on engine). Note the modified distributor cap and location of rotor pointing just past #1 terminal.

Ok I did set it a 0 but I didn't do the screwdriver in the slot to hold it in place. I turned the bottom harmonic wheel to till the rotor was alittle past 6oclock and my oil pump was at 11 oclock. Lets just say I remove it with your method wont it still be set at the same position? I'm just an old let me try weekend mechanic. But when I broke down on the highway and got towed off I tried my best.lol I'm gonna give your method a shot. I really appreciate your advice so much. You know I've gone to several diagnostic shops with so much equipment and lit signs and BUT! it doesn't mean they a real mechanics working there. thank you I will try your way this weekend.:idea:My guess is that if the rotor was that damaged from the distributor shaft movement that the Camshaft Position Sensor may have been damaged as well. And if you reused this Cam Sensor when you replaced the distributor it may be the root cause of your problem.

~~~~~~~

You can check the distributor timing relatively easily by doing the following:

Remove the radiator electric fan so you can get a direct view of the crankshaft damper timing slot on it.

Remove the distributor cap, rotor, and Cam Sensor.

Rotate the crank damper in a clockwise direction until the timing slot on the damper aligns with the zero (0) timing mark on the timing chain cover timing mark. See pic.

Reinstall the rotor only.

The rotor should be pointing just past the #1 spark plug terminal Not the #6 terminal. See pic.

Using a 3/16" pin punch or drill bit, you should be able to insert the punch through the alignment hole in the plastic ring in the distributor and down thru the alignment hole in the distributor base. If it won't pass thru the hole in the distributor base the distributor is improperly installed. See pics.

Timing marks:

Pin punch installed in plastic ring:

Pin punch installed (on engine). Note the modified distributor cap and location of rotor pointing just past #1 terminal.

Sidewinder CC

NAXJA Forum User

- Location

- Canton, Michigan

Ok I did set it a 0 but I didn't do the screwdriver in the slot to hold it in place. I turned the bottom harmonic wheel to till the rotor was alittle past 6oclock and my oil pump was at 11 oclock. Lets just say I remove it with your method wont it still be set at the same position? I'm just an old let me try weekend mechanic. But when I broke down on the highway and got towed off I tried my best.lol I'm gonna give your method a shot. I really appreciate your advice so much. You know I've gone to several diagnostic shops with so much equipment and lit signs and BUT! it doesn't mean they a real mechanics working there. thank you I will try your way this weekend.:idea:

If you find that the rotor is pointing at #6 cylinder turn the damper 360 degrees to align the timing marks again. The rotor should be pointing at #1 now. If you go past the zero timing mark, back the damper up 90 degrees and go at it again slowly. Bump the ratchet or breaker bar you are using to turn the damper (3/4" socket) with the palm of your had the last few degrees when approaching zero.

When you get the rotor pointing near #1 you can remove the distributor, Install the 3/16" drift, do not move the damper from the zero timing mark, align the oil pump drive at about the 11:00 o'clock position and with the hold down fork at the 1:00 o'clock position (see pic), then install the distributor. It will rotate in to place with the hold down fork centered on the hold down bolt hole.

Good luck.

My fellow xj owner. Thank you so very much for the step by step instructions. So I did as you showed me. Getting the rotor to the presice mark is not easy. It's just a nitch off the mark. I tried and tried. But she starts. And runs well, But I'm getting the sputters on take off, They go away as I accelerate. And they return as I get onto the highway climbing higher speeds. The sputters start at 60 and 65 mph. Now though I'm getting the crank and cam sensor codes together. Do you think I should go OEM Mopar? Thanks again for all your help. :looney:

Sidewinder CC

NAXJA Forum User

- Location

- Canton, Michigan

My fellow xj owner. Thank you so very much for the step by step instructions. So I did as you showed me. Getting the rotor to the presice mark is not easy. It's just a nitch off the mark. I tried and tried. But she starts. And runs well, But I'm getting the sputters on take off, They go away as I accelerate. And they return as I get onto the highway climbing higher speeds. The sputters start at 60 and 65 mph. Now though I'm getting the crank and cam sensor codes together. Do you think I should go OEM Mopar? Thanks again for all your help. :looney:

I would suggest a Camshaft Position Sensor instead of a Crankshaft Position sensor at this point, in that you have a cam/crank code.

Mopar sensors are the best (if you can afford them).

I wouldn't rule out the TPS. There could be a dead spot in the TPS variable resistor at the spot where you cruise. There's a test you can do for this if you're interested.

Similar threads

- Replies

- 27

- Views

- 862

- Replies

- 8

- Views

- 171

- Replies

- 27

- Views

- 2K