UncleSarge58

NAXJA Forum User

Keep Getting : P1391- Intermittent Loss of CMP or CKP.

Tried 3 Different Crank Pos. Sensors. Get Same Reading.

Engine Runs ROUGH, MisFires & Stalls at Idle.

Also Shifts Erratically & won't Hold OD.

Tried Clearing Codes & Resetting ECM Memory.

Still getting Same Code.

To Try & Cure Misfire & Rough Idle, I Have Replaced:

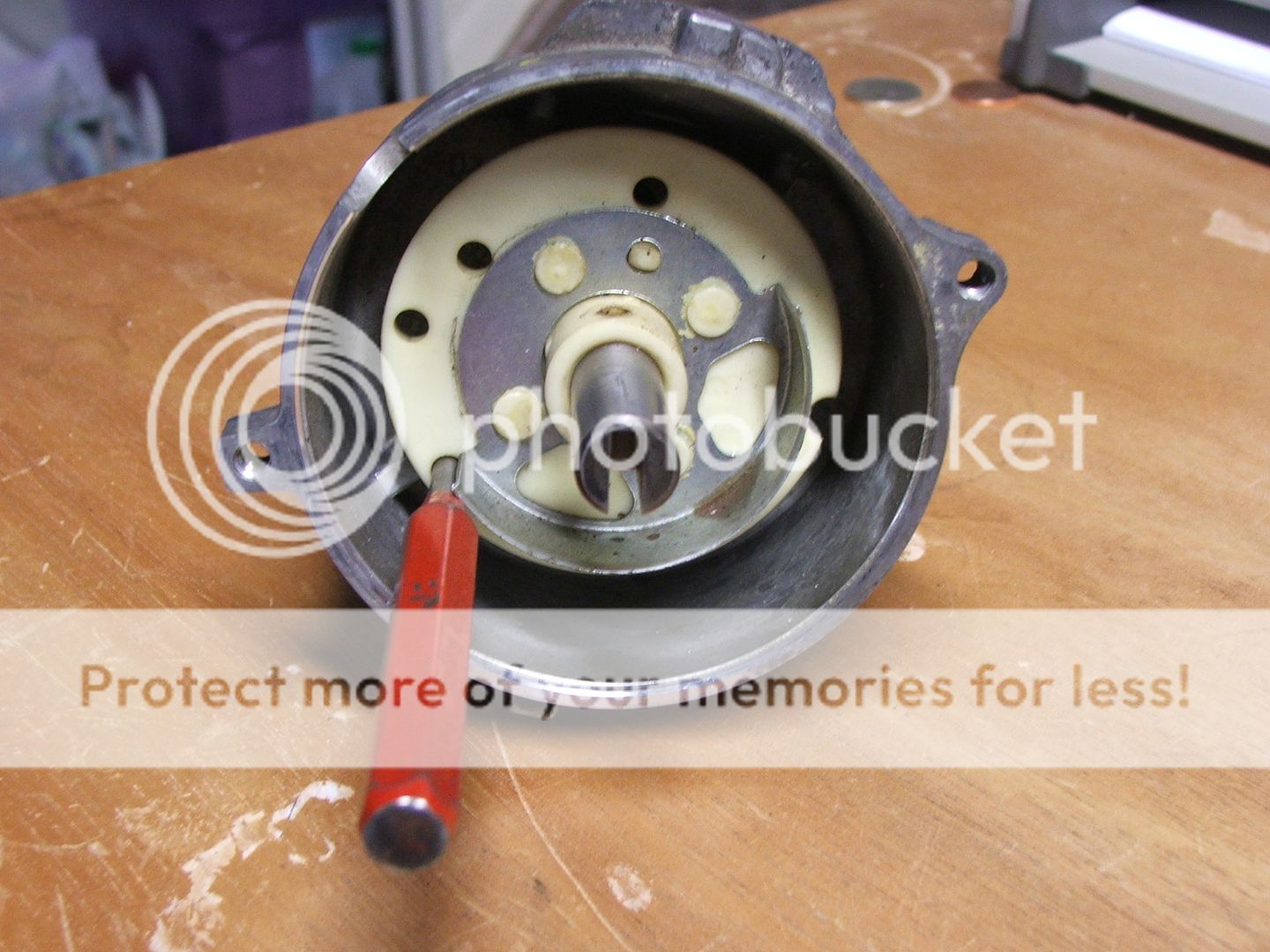

1) New Distributor w/ New Cam Pos. Sensor plate, Cap & Rotor.

2) New Copper Spark Plugs & 7mm Plug Wires.

3) New CPS, MAP & TPS Sensors. New Idle Control Unit.

4) New Coolant & Manifold Temp. Sensors & New T-Stat.

5) All New 4 Hole Injectors w/ New O-Rings.

6) New Neutral Safety Switch (NSS)

7) New Trans Shift Solenoids, Gasket, Filter & Fluid.

8) New Fuel Pump, Sock & Filter.

9) Antifreeze, Oil & Filter Changed Too.

After All This, Looks Like the Computer (ECM) is Failing.

Any Clues as to, How to Check or FIX the ECM?

Anything I'm Missing Here? Or, Should I just Replace the ECM?

HELP!!! This thing is Costing me a Fortune & Lots of Time.

UncleSarge58

Tried 3 Different Crank Pos. Sensors. Get Same Reading.

Engine Runs ROUGH, MisFires & Stalls at Idle.

Also Shifts Erratically & won't Hold OD.

Tried Clearing Codes & Resetting ECM Memory.

Still getting Same Code.

To Try & Cure Misfire & Rough Idle, I Have Replaced:

1) New Distributor w/ New Cam Pos. Sensor plate, Cap & Rotor.

2) New Copper Spark Plugs & 7mm Plug Wires.

3) New CPS, MAP & TPS Sensors. New Idle Control Unit.

4) New Coolant & Manifold Temp. Sensors & New T-Stat.

5) All New 4 Hole Injectors w/ New O-Rings.

6) New Neutral Safety Switch (NSS)

7) New Trans Shift Solenoids, Gasket, Filter & Fluid.

8) New Fuel Pump, Sock & Filter.

9) Antifreeze, Oil & Filter Changed Too.

After All This, Looks Like the Computer (ECM) is Failing.

Any Clues as to, How to Check or FIX the ECM?

Anything I'm Missing Here? Or, Should I just Replace the ECM?

HELP!!! This thing is Costing me a Fortune & Lots of Time.

UncleSarge58