Just A WAG (wild arsed guess) as I've never set mine up wrong, either accidentally or on purpose, so I don't really know what will happen. A lot of the diagrams show the number one pole on the distributor at the six O'clock position (while standing on the passengers side of the motor lloking towards the drivers side), which is a bit misleading.

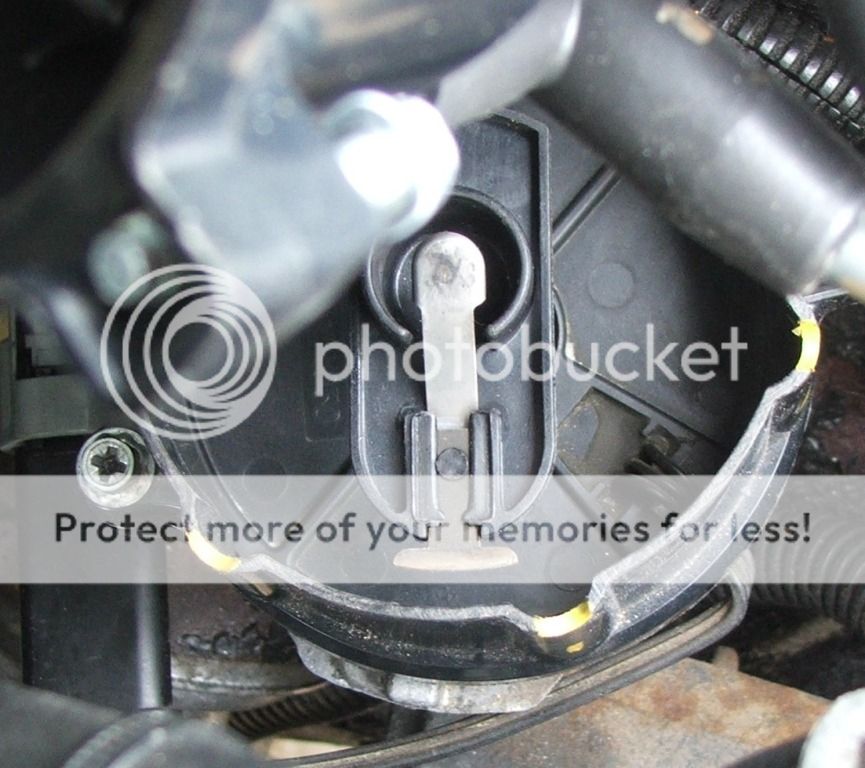

When the no.1 piston is at TDC at the end of the compression stroke, the rotor should be pointing in the direction shown (five o'clock position when standing on the passenger side looking towards the driver's side).

Picture here,

http://www.angelfire.com/my/fan/dist_index.html

Camshaft Position Sensor

The camshaft position sensor is located in distributor. This

Hall Effect type sensor works in conjunction with engine speed signal

of crankshaft position sensor providing PCM with inputs necessary to

establish and maintain proper fuel injector firing order.

When leading edge of pulse ring enters the sync signal

generator on the camshaft position sensor, the resulting change in the

magnetic field causes a 5-volt reference signal to be induced. On 4-

cylinder engines, this indicates to the PCM that piston No. 4 will be

the next piston at Top Dead Center (TDC). On 6-cylinder engine, it

indicates that piston No. 3 will be at TDC.

When trailing edge of pulse ring leaves the sync signal

generator on the camshaft position sensor, the resulting collapse of

the magnetic field causes reference signal to drop to zero volts. On

4-cylinder engines, this indicates that piston No. 1 will be the next

piston at TDC. On 6-cylinder engine, it indicates that piston No. 4

will be at TDC.

I really don't know what will happen if you plug number one into the number five pole on the distributor on the initial setup. But it will clock the cam position sensor wrong and is likely to send conflicting info to the PCM. Just a possibility that should be looked at closely.

It is also easy to mistake the top of the exhaust stroke for the top of the compression stroke. The main reason I don't use my finger and use a compression gauge when trying to find TDC. It can build a little pressure on the exhaust stroke and you may mistake it for compression.

You may have to pull off the valve cover and verify TDC. Compression stroke on number one, timing marks aligned with the last turn to the right facing the motor (don't back up or if you have to back way up and then try again). *Both of the number one valves closed, rockers a high as they go, you can usually wiggle both a rockers a little, they will be loose enough to have a bit of sideways play.* It's possible (I have to guess) to have the timing chain clocked wrong and this may be causing sensor to PCM conflicts. No telling how the PCM is going to react to really wrong sensor inputs, I doubt the engineers programmed for every possible failure mode..

The only time I've ever seen an ASD relay chatter it was a bad connection, at a splice in the harness. Mine was at/near the dealer installed anti theft module. My issue was on the power into the actuator coil inside the ASD relay and not on the ground side of the actuator coil going to the PCM or the PCM (because of faulty sensor inputs) pulsing the ground). But it is unlikely I've seen every possible permutation that would cause the ASD relay to chatter.

Just some ideas. When I get really stuck I back up and start over from the beginning and recheck my initial setup and the first thing to do is verify TDC. Don't skip any steps and assume anything, motor basics 101.

My hunch is you have a conflict between the Cam position sensor and the crank position sensor. Or maybe something simple like the CPS isn't reading the tone ring for whatever reason.

I'm old as dirt and my memory fails somewhat. But I seem to remember one guy going nuts because he used the wrong bolts for the CPS. I don't remember exactly what the issue was, he maybe used accidentally magnetized bolts or whatever. But a new set of OEM CPS bolts cured his issues. A long shot but if all else fails, something to try.