Kingkong0192

NAXJA Forum User

- Location

- New Milford, CT

I know this is a bunch, but this is my first time ever pulling a transmission and i want to do it right so i don't have to pull it back out because i messed something up putting it back in.

Long story short, my driveshaft managed to bind, causing the T-case to be violently ripped out of my jeep and thrashing the transmission at the same time.

Just pulled the transmission out tonight.

My main concern it with all the wires/sensors that go to the Transmission and the torque convertor/flexplate area.

1. Do i prefill the torque converter with transmission fluid? Is there a way to test a torque converter?

2. How do i tell if my flexplate is boogered?

3. The NSS. When i undid the big nut i heard the thing ratchet and i saw the adjustment inside the transmission move (i had the pan off.) What does this adjust and how do i know where to set it?

I'm probably missing a bunch of questions, but i'm tired, and i'm going to bed. I'll update this tomorrow. Thanks.

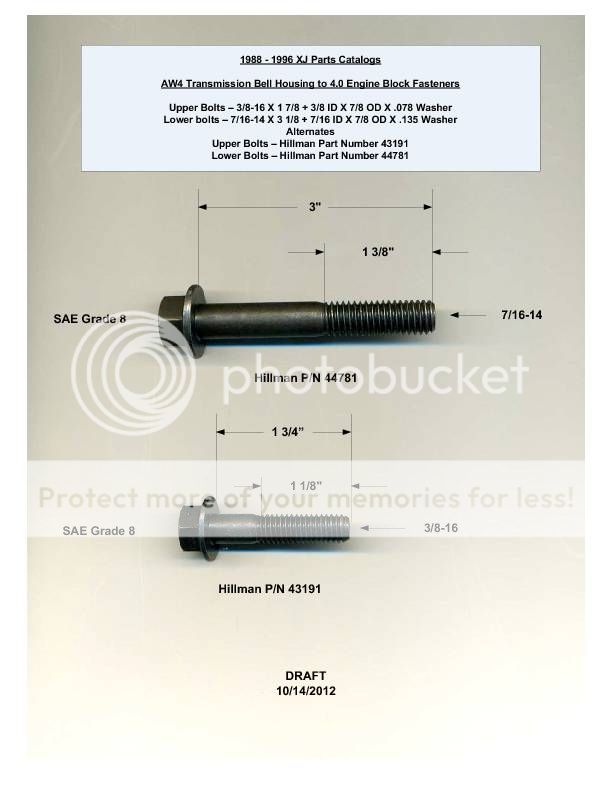

Oh, and some pictures. I didn't realize the entire transmission was cracked from the starter all the way over the bellhousing to the other side making about half the bolts holding it on useless.

Long story short, my driveshaft managed to bind, causing the T-case to be violently ripped out of my jeep and thrashing the transmission at the same time.

Just pulled the transmission out tonight.

My main concern it with all the wires/sensors that go to the Transmission and the torque convertor/flexplate area.

1. Do i prefill the torque converter with transmission fluid? Is there a way to test a torque converter?

2. How do i tell if my flexplate is boogered?

3. The NSS. When i undid the big nut i heard the thing ratchet and i saw the adjustment inside the transmission move (i had the pan off.) What does this adjust and how do i know where to set it?

I'm probably missing a bunch of questions, but i'm tired, and i'm going to bed. I'll update this tomorrow. Thanks.

Oh, and some pictures. I didn't realize the entire transmission was cracked from the starter all the way over the bellhousing to the other side making about half the bolts holding it on useless.