-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

- Home

- Forums

- NAXJA Unibody Jeep Technical Forums

- Jeep Cherokee XJ (1984 - 2001)

- Modified Tech Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

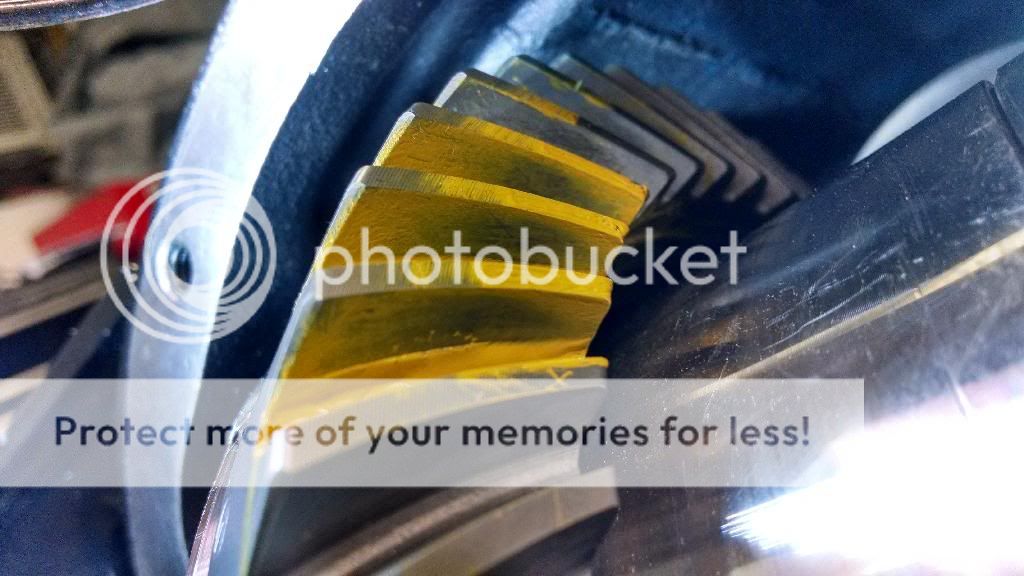

Comments on gear pattern please...

- Thread starter whitexj98

- Start date

Digger87xj

NAXJA Forum User

- Location

- Buffalo Creek/Lakewood CO

open the b/l to .008"

Digger87xj

NAXJA Forum User

- Location

- Buffalo Creek/Lakewood CO

Perfect.

jeeperjohn

NAXJA Forum User

- Location

- Temecula, CA

The pattern is too deep. I would take out about .005" of shim and see what it looks like then.

Digger87xj

NAXJA Forum User

- Location

- Buffalo Creek/Lakewood CO

yeah... now i see it on my desktop and not on phone, -.005 on the pinion and same b/l would be better

Last edited:

Digger87xj

NAXJA Forum User

- Location

- Buffalo Creek/Lakewood CO

- Location

- Rainy side of Washington

The last set of pics looks good to me, but I'm curious. What diff is this? d30? 8.25? 44? low or high pinion?

Digger87xj

NAXJA Forum User

- Location

- Buffalo Creek/Lakewood CO

HP D30

Digger87xj

NAXJA Forum User

- Location

- Buffalo Creek/Lakewood CO

well, that said.. It'll run 90% of it's life with the ring gear pushing the pinion, which is the coast side of the tooth. That side of the pattern is picture perfect.

bobnoxious

NAXJA Forum User

- Location

- Marion, MA

HP 30, and there is no shims under the pinion, only the baffle. So I can't really reduce..

Are you reusing the stock pinion baffle? Are there shims under the race in the housing? The aftermarket baffles are much thinner than the OEM ones, allowing for shims under the race.

Backlash adjustments are not for adjusting pattern.

MoparManiac

NAXJA Forum User

- Location

- Amherst, NH

^^^Listen to this man.

I'd say you're too deep and would pull .003 out from under the race/inner bearing (wherever the shims are).

I'd say you're too deep and would pull .003 out from under the race/inner bearing (wherever the shims are).

jeeperjohn

NAXJA Forum User

- Location

- Temecula, CA

HP 30, and there is no shims under the pinion, only the baffle. So I can't really reduce..

I have encountered this a few times. You will need to remove the baffle and add some thin shims. I have done this a few times and never had any oiling issues.

- Location

- Lakeside, CA

How thick is the baffle? You should have a slinger underneath the bearing at the pinion head, then baffle/shims under the race. Have you got the race seated all the way, are there any burrs?

RWKHausSupply

NAXJA Forum User

- Location

- yorba linda, Cali

I bet hes running the stock .057 ~ .063 slinger, and then some baffle under race. You should have replaced the stock slinger (how dana sets depth in OE app), with the one in the master kit, and when you do that, then you have to add shim under race.

There is NO Picture perfect there. Deep both sides. Close enough that you Might not have any issues ever, especially in a front D30, but not right.

There is NO Picture perfect there. Deep both sides. Close enough that you Might not have any issues ever, especially in a front D30, but not right.

- Location

- Rainy side of Washington

I bet hes running the stock .057 ~ .063 slinger, and then some baffle under race. You should have replaced the stock slinger (how dana sets depth in OE app), with the one in the master kit, and when you do that, then you have to add shim under race.

There is NO Picture perfect there. Deep both sides. Close enough that you Might not have any issues ever, especially in a front D30, but not right.

I have never seen a slinger setting the depth, always shims under the inner race, and I've torn down every single factory axle I have ever scrapped. Also there is a pinion depth+preload shim package in the parts catalog (8350 0192) and a single slinger part number with no thickness listed.

RWKHausSupply

NAXJA Forum User

- Location

- yorba linda, Cali

I have never seen a slinger setting the depth, always shims under the inner race, and I've torn down every single factory axle I have ever scrapped. Also there is a pinion depth+preload shim package in the parts catalog (8350 0192) and a single slinger part number with no thickness listed.

I have Never seen a Dana OE assembled D30, D30R, D44, D44JK, D44RS have any make up shim under the race or under the head. They assemble with the main pinion slinger as setting depth. On early D30R they also accounted for some of this with the baffle thickness. I assemble about 5 axles a week. Its poss if there was one or more that did have make up shims under the race that those customers only bought a mini kit, and I adjusted with under the head.

I Never remove the race unless needed. With the correct tools, removing the bearing is much better and easier. There are more damaged then not, D44R housings from the mix of removing the race and poor QC (early stuff so) that have the inner race fall out.

- Location

- sacramento

Similar threads

- Replies

- 2

- Views

- 3K

- Replies

- 0

- Views

- 125