Sneaky

NAXJA Forum User

- Location

- Kelso, Washington

I got my flares the other day and was stressing about the instal of the rear so that's where I started today. I thought it out pretty well and was really concerned about sealing up all of the radius cuts. Ill explain what I did step by step.

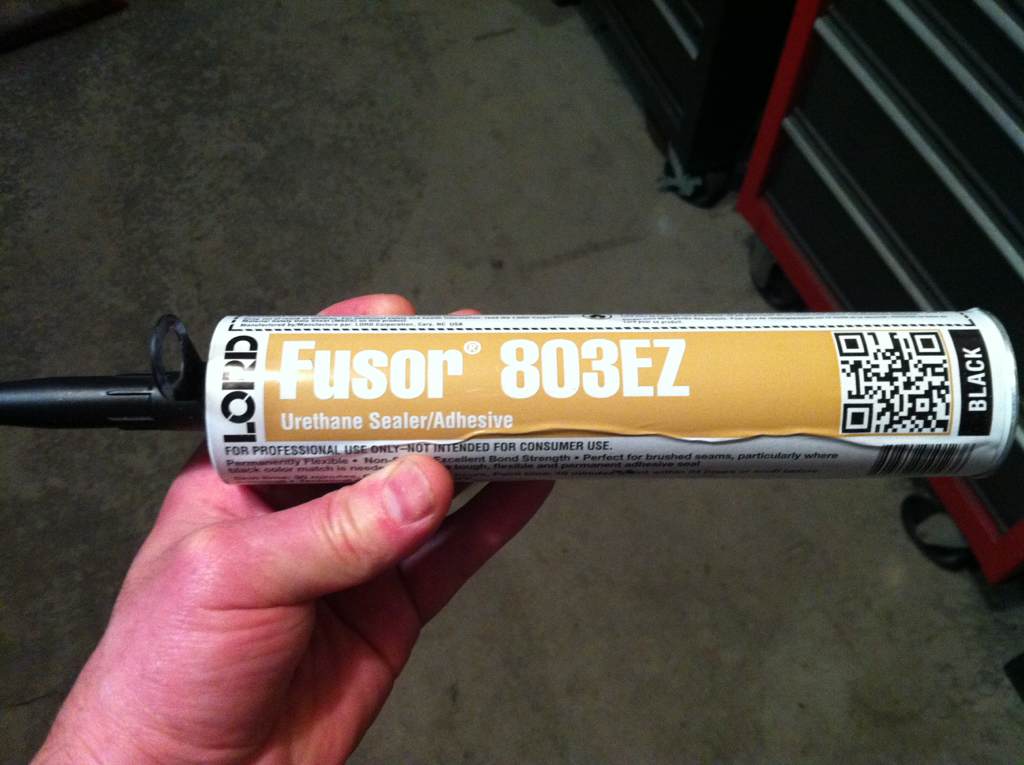

First I got all my tools/materials gathered.

Then started out by getting the right side of the Jeep off of the ground.

Then took the wheels off

Not too eventful yet, I know...

Had to remove the flare and bumper cap.

Then I removed the door trim so I can trim it down when done and reinstall.

Then I tried to place the flares on the jeep to get my reference lines... Pretty difficult in my opinion so I just started cutting. With some research I had a pretty good idea of how far for the first cut and where to do the radius cuts.

After the first cut I followed it up with a paddle wheel.

After that I had marked all of the spot welds and my cuts I was going to make.

Notice I hadn't marked my cuts in the photo...

To make sure I had a clean surface on the back side for primer and my urethane sealer I wire wheeled the back lip.

Once that was done I sealed it with some self etching primer.

Here's my cut lines.

Then I cut all radius cuts with the air hacksaw. Then followed up with sealer on the back side so that it would be sealed really well once I folded the metal back.

After that I folded back the metal and then did some more sealer and fully capped all the bent back tabs.

First I got all my tools/materials gathered.

Then started out by getting the right side of the Jeep off of the ground.

Then took the wheels off

Not too eventful yet, I know...

Had to remove the flare and bumper cap.

Then I removed the door trim so I can trim it down when done and reinstall.

Then I tried to place the flares on the jeep to get my reference lines... Pretty difficult in my opinion so I just started cutting. With some research I had a pretty good idea of how far for the first cut and where to do the radius cuts.

After the first cut I followed it up with a paddle wheel.

After that I had marked all of the spot welds and my cuts I was going to make.

Notice I hadn't marked my cuts in the photo...

To make sure I had a clean surface on the back side for primer and my urethane sealer I wire wheeled the back lip.

Once that was done I sealed it with some self etching primer.

Here's my cut lines.

Then I cut all radius cuts with the air hacksaw. Then followed up with sealer on the back side so that it would be sealed really well once I folded the metal back.

After that I folded back the metal and then did some more sealer and fully capped all the bent back tabs.