glamisdunin

NAXJA Forum User

- Location

- the paradise city

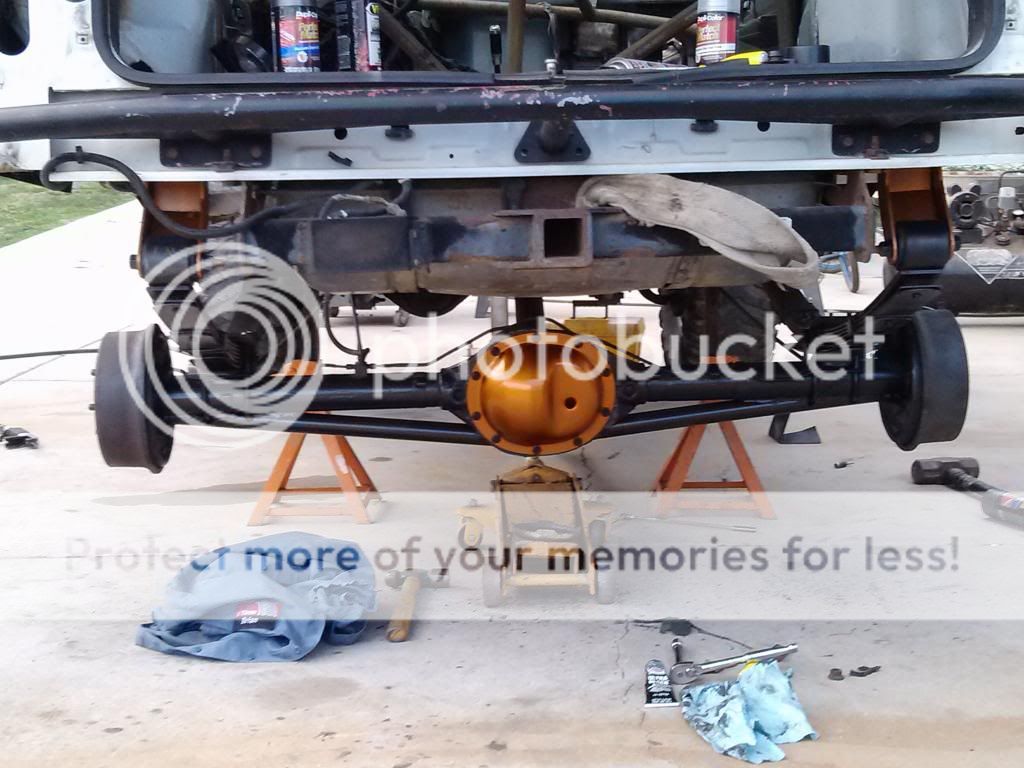

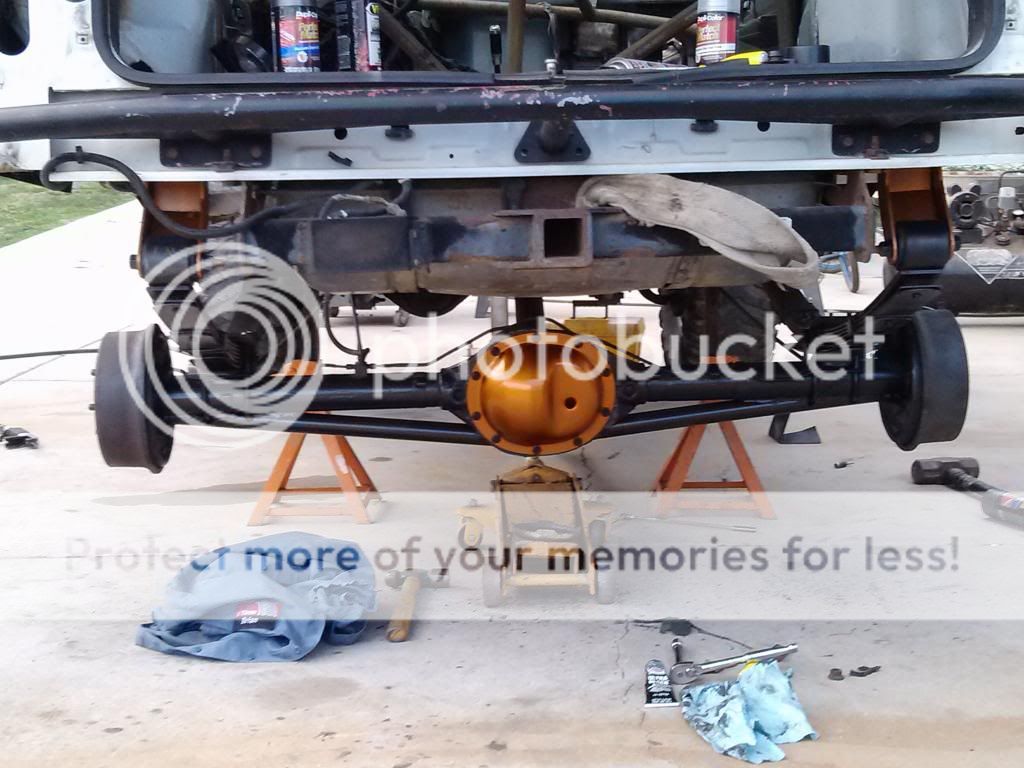

So we built some rear fenders on one of my xj's recently and they were designed for a stretched wheel base for when we make our mild 4 link kit. Untill i have enough funding however i have decided to venture into a leaf spring flip. To put the tire closer to center of wheel well. Its not finished yet i still need to finish the cage for shock locations and design a traction bar to prevent an axle wrap issue from having the soft side of the spring forward. Before i recieve any comments on how you woyld not recommend this this is only temporary. This xj is an amc model 1990 4.0 with 242 t case. In the past i had an issue for not converting to an sye kit and this spring flip has helped with this issue. My wheel base is now105.5 inches i have stock leaf pack with add a leafs we built our shackles and shackle mount will tie into d pillar of the cage when completed. I used a stock driveline from an 86 4 cyl. 4 wheel drive manual which was about 5 inches longer and magically fit perfectly in its new home. Hope you guys like the build so far. This jeep is only one of 5 that we are currently building.