- Location

- MilkyWay Galaxy

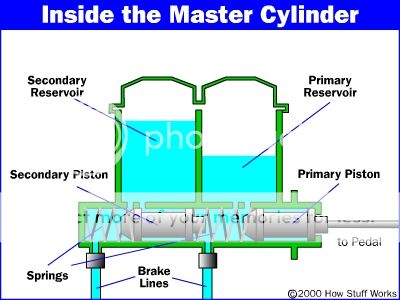

I have been trying to solve the unsolvable problem of a mushy peddle when the engine is running and hard peddle when the engine is off. The MC is new (Autozone). I have a looong debugging thread that has been a work in progress for a very long time, but here is the short part of the current story, question today:

I have heard rumors that MCs should be bench bleed (like in a bench vise?) before mounting, but I have bleed mine while mounted on the vacuum booster the last 8 years or so with the little tubing kits and plastic holder that comes with the MC before I connected the brake lines. Bench bleeding and transport and mounting....a filled and bled MC seemed messier and more problematic than doing it mounted on the VacBoster to me.

Has anyone else had a problem doing this on a Renix jeep era MCs (or similar ones) and found air trapped in the MC by not bench bleeding first, versus bleeding while mounted on the VacBooster, and found the air bubble in the MC would stay there forever, with out a dismounted bench bleed? And old timer is telling me to pull it and bench bleed it, but I find it hard to believe that is the problem. I am thinking of re-bleeding at the MC using the vehicle tube fittings on the side of the MC. But if it is a rod travel distance issue will that work?

If that is not the issue, then my second question is has any one had a brand new MC that bleed fine and had a super hard peddle, normal feel with the engine off, and then the peddle turned to mush and nearly goes to the floor with the engine on at full vacuum in idle - park? The booster is only a year or two old and working very well, maybe too well, LOL.

My old thread is here showing that we have done every other conceivable thing multiple times!!!!

http://www.naxja.org/forum/showthread.php?t=1019972

My second question, is could the new MC have good enough seals, piston cups, to seal and hold pressure with no vacuum boost, but be leaking internally under the higher boost pressure? There are no external leaks, I have put 3000 miles on it with no loss of fluid.

I have heard rumors that MCs should be bench bleed (like in a bench vise?) before mounting, but I have bleed mine while mounted on the vacuum booster the last 8 years or so with the little tubing kits and plastic holder that comes with the MC before I connected the brake lines. Bench bleeding and transport and mounting....a filled and bled MC seemed messier and more problematic than doing it mounted on the VacBoster to me.

Has anyone else had a problem doing this on a Renix jeep era MCs (or similar ones) and found air trapped in the MC by not bench bleeding first, versus bleeding while mounted on the VacBooster, and found the air bubble in the MC would stay there forever, with out a dismounted bench bleed? And old timer is telling me to pull it and bench bleed it, but I find it hard to believe that is the problem. I am thinking of re-bleeding at the MC using the vehicle tube fittings on the side of the MC. But if it is a rod travel distance issue will that work?

If that is not the issue, then my second question is has any one had a brand new MC that bleed fine and had a super hard peddle, normal feel with the engine off, and then the peddle turned to mush and nearly goes to the floor with the engine on at full vacuum in idle - park? The booster is only a year or two old and working very well, maybe too well, LOL.

My old thread is here showing that we have done every other conceivable thing multiple times!!!!

http://www.naxja.org/forum/showthread.php?t=1019972

My second question, is could the new MC have good enough seals, piston cups, to seal and hold pressure with no vacuum boost, but be leaking internally under the higher boost pressure? There are no external leaks, I have put 3000 miles on it with no loss of fluid.