willsmysticcobra

NAXJA Forum User

- Location

- Lake Zurich IL

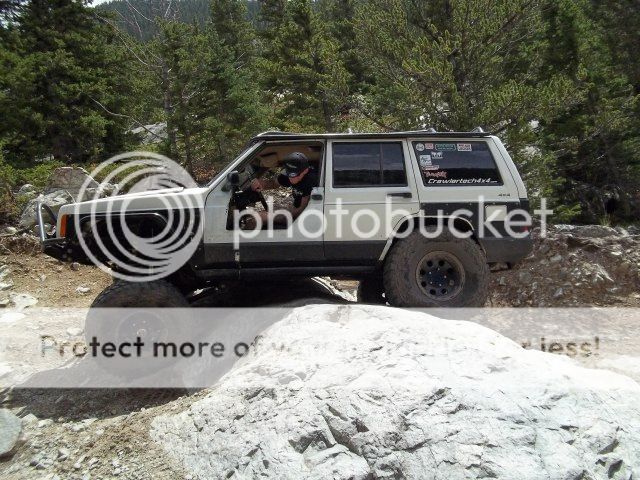

This is breaking my heart. It clearly separated at the body seam.... thoughts?

Dont forget, doubled up or differant thickness sheetmetal will show up on black vehicles in the sun, due to varied rates of expansion/contraction.

The good news is, its only a jeep, AND half of that will be covered by the flair.

Regular ole great stuff is open cell, it will attract and hold moisture.... not exactly what your looking for.

If your talking to body shops, be up front with them, let em know you basically DGAF, but just want it covered and sealed... You might just run into somebody who will hustle that shit on the side.