I've seen it mentioned already in this thread, and I'll second it. Test the TPS. Grab a few at the junk yard if you can. My '96 (yeah, I know, different ignition!) was acting the same, only the engine was joining in the fun sometimes. It was the TPS, randomly and intermittantly confusing the tranny into weird shifting, and dropping in and out of convertor lock-up. A new one didn't work, but a variety of previously loved ones yielded one that was just right. Cheap fix, and worth a try. Look up the part number on a website (Rock Auto, Advance, etc.), and Google the number, and you should come up with other vehicles it could cross-reference to, enlarging the pool of potential donors. Good luck!

87 to 90 4.0s with an auto trans. Here's how to test the TPS:

RENIX TPS ADJUSTMENT

Before attempting to adjust your TPS be sure the throttle body has been recently cleaned. It's especially important that the edges of the throttle butterfly are free of any carbon build-up.

IMPORTANT NOTE: With the Key OFF, and using the positive (red) lead of your ohmmeter, probe the B terminal of the flat 3 wire connector of the TPS. The letters are embossed on the connector itself. Touch the black lead of your meter to the negative battery post. Wiggle the wiring harness where it parallels the valve cover and also over near the MAP sensor on the firewall. If you see more than 1 ohm of resistance, or fluctuation in your ohms reading, some modifications to the sensor ground harness will be necessary. The harness repair must be performed before proceeding. I can provide an instruction sheet for that if needed.

MANUAL TRANSMISSION:

RENIX manual transmission equipped XJs have a three-wire TPS mounted on the throttle body. This manual transmission vehicle TPS provides data input to the ECU. The manual transmission TPS has three wires in the connector and they're clearly embossed with the letters A, B, and C. Wire "A" is positive. Wire "B" is ground. Key ON, measure voltage from "A" positive to "B" ground by back-probing the connectors. Note the voltage reading--this is your REFERENCE voltage. Key ON, back-probe the connector at wires "B" and "C". Measure the voltage. This is your OUTPUT voltage. Your OUTPUT voltage needs to be seventeen percent of your REFERENCE voltage. For example: 4.82 volts X .17=.82 volts. Adjust the TPS until you

have achieved this percentage. If you can't achieve the correct output voltage replace the TPS and start over.

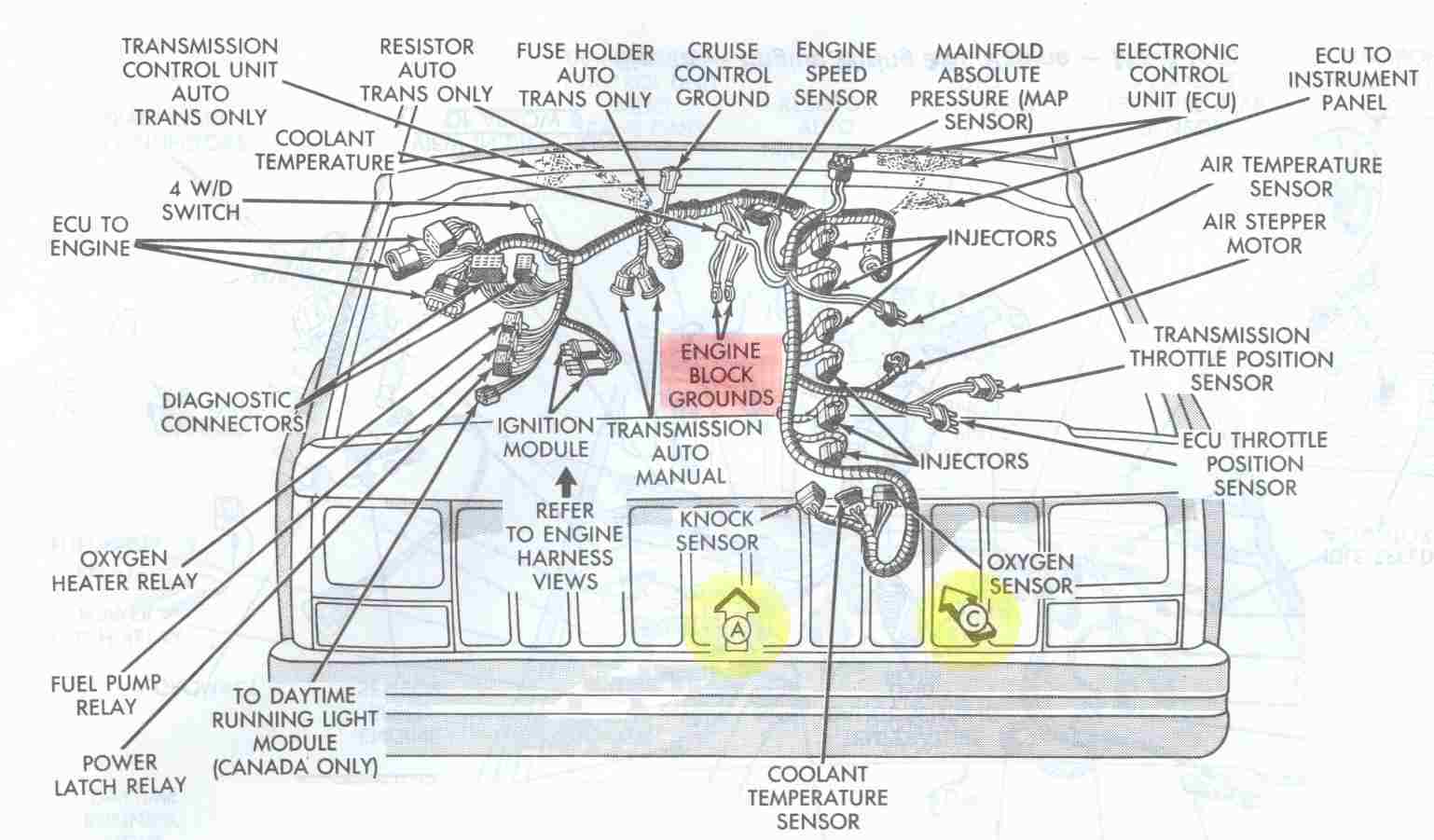

AUTOMATIC TRANSMISSION: RENIX automatic transmission equipped XJs have a TPS with two connectors. There is a flat three-wire connector, same as the manual transmission vehicles have, and it is tested the same as the manual transmission equipped vehicles—FOR ENGINE MANAGEMENT RELATED ISSUES.

However, the automatic TPS also has a square four-wire connector clearly embossed with the letters A,B,C, and D. It only uses three wires and provides information to the Transmission Control Module. Key ON, measure voltage between "A" positive and "D" ground. Note the voltage. This is your REFERENCE voltage. Back-probe the connector at wires "B" and "D". Measure the voltage. This is your OUTPUT voltage. Your OUTPUT voltage needs to be eighty-three percent of your REFERENCE voltage. For example 4.8 volts X .83=3.98 volts. Adjust the TPS until you have achieved this percentage. If you can't, replace the TPS and start over. So, if you have an automatic equipped XJ your TPS has two sides--one side feeds the ECU, and the other side feeds the TCU.

FOR AUTOMATIC TRANSMISSION RELATED ISSUES. Check the four-wire connector side of the TPS.

If you have ENGINE issues check the three-wire connector side of the TPS. For those with a MANUAL TRANSMISSION--the TPS for the manual transmission XJs is stupid expensive. You can substitute the automatic transmission TPS which is reasonably priced.

Revised 05-28-2012