Blind Driver

NAXJA Forum User

- Location

- West Chester Pa

Ok so I've been thinking of building a ladder for my roof rack for a while now. I didn't think I would need one but I tore the tendons in my shoulder and trying to pull myself up was too difficult. I didn't want one that was permanent because I didn't want to have the blocked rear window and I couldn't find a good war to mount it on the sides. I got the idea from a ladder I saw in Venice. My idea was to have it clip onto the rack and have it rest on the bumper. I used 3/4 inch square to match the rack and the angles are 1 inch. I will finish tomorrow but figured I would take you a taste of what I've done so far.

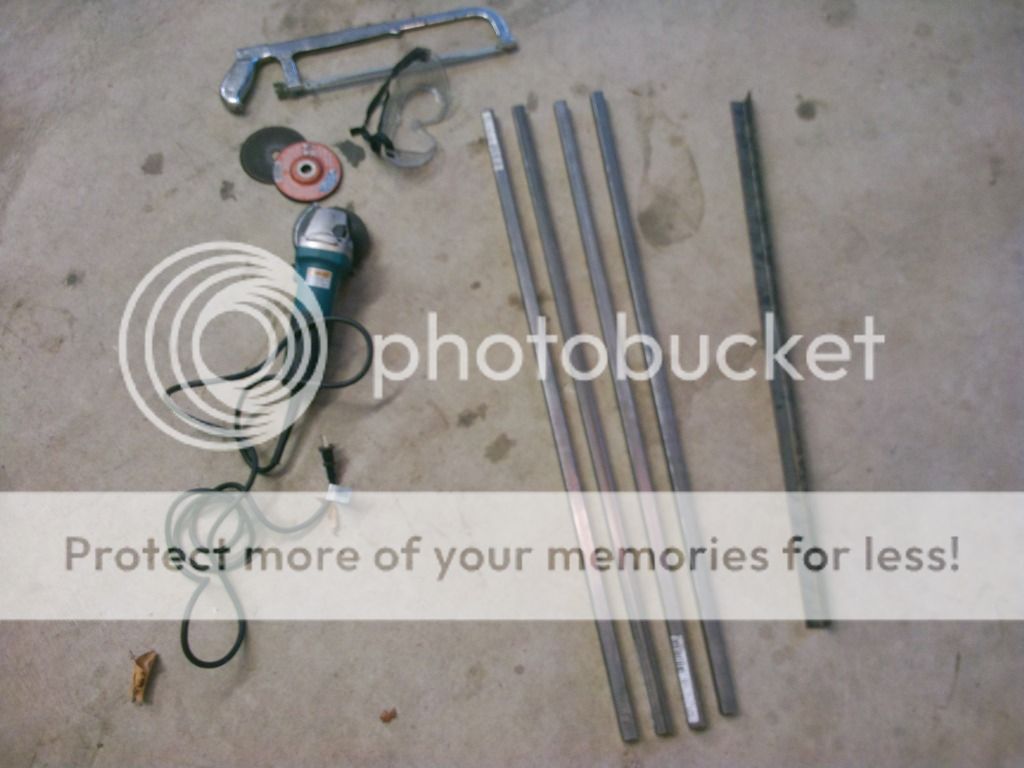

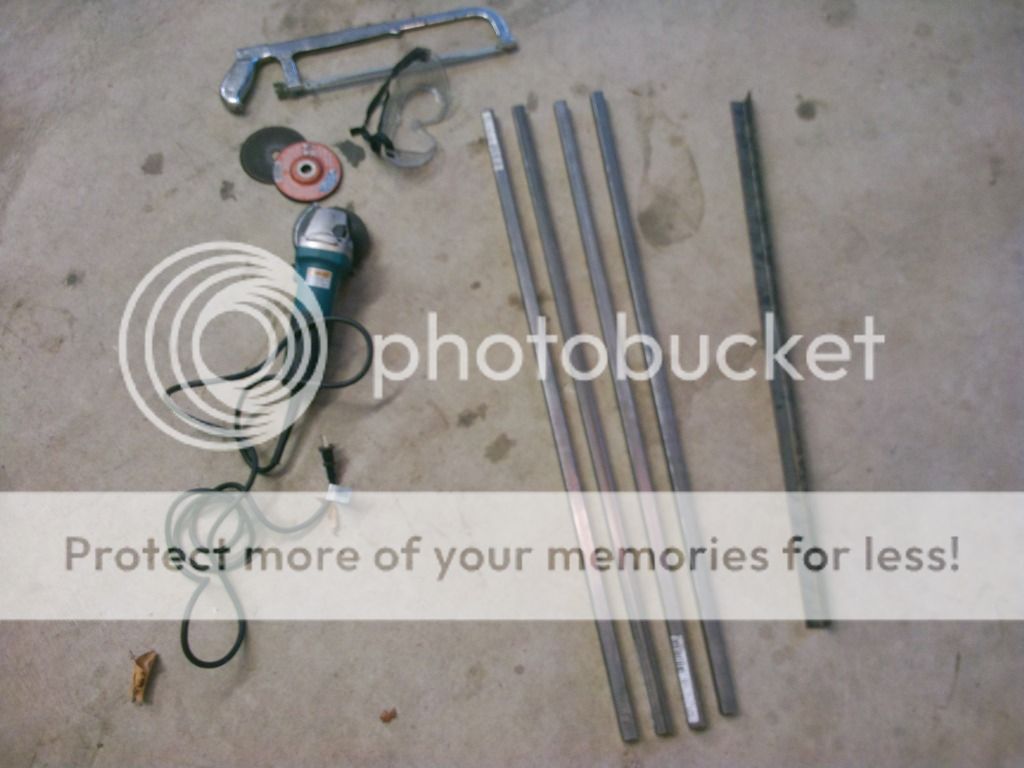

Picture of everything I used. Tools and materials.

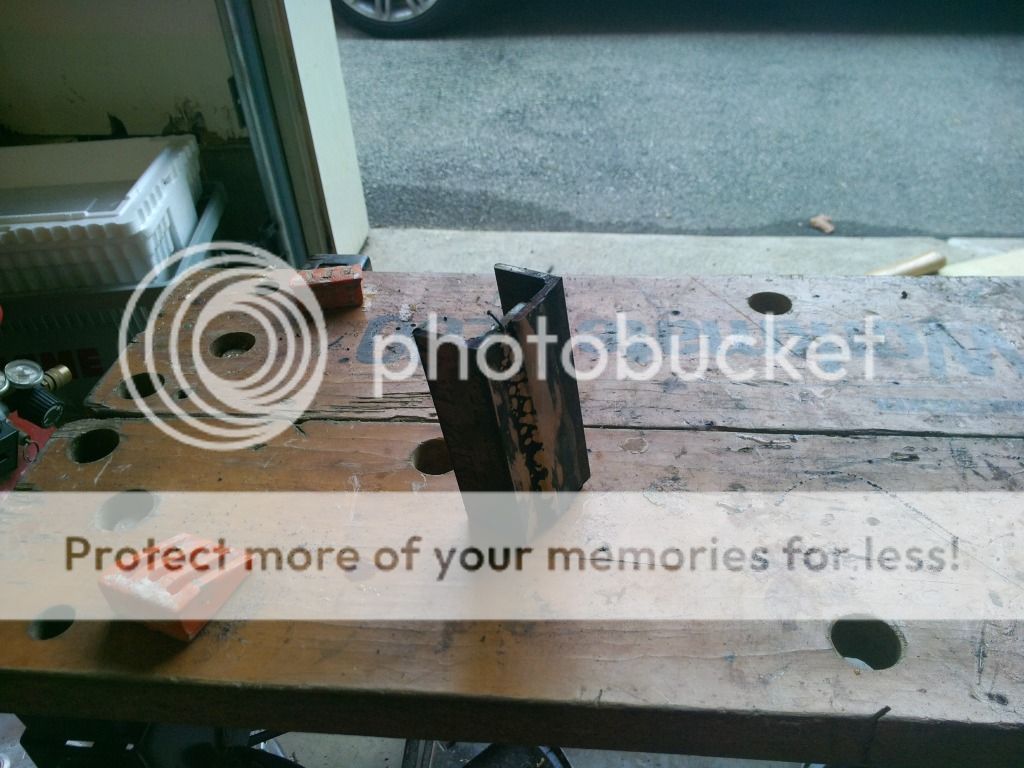

Just mocked up to get angles and measurement

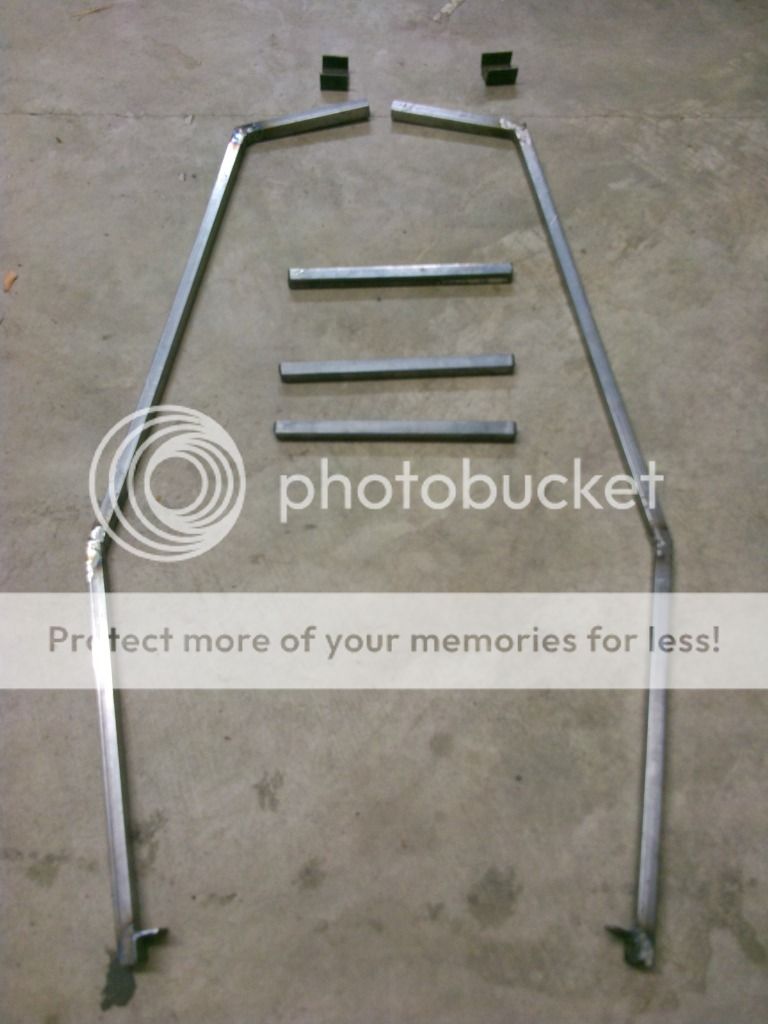

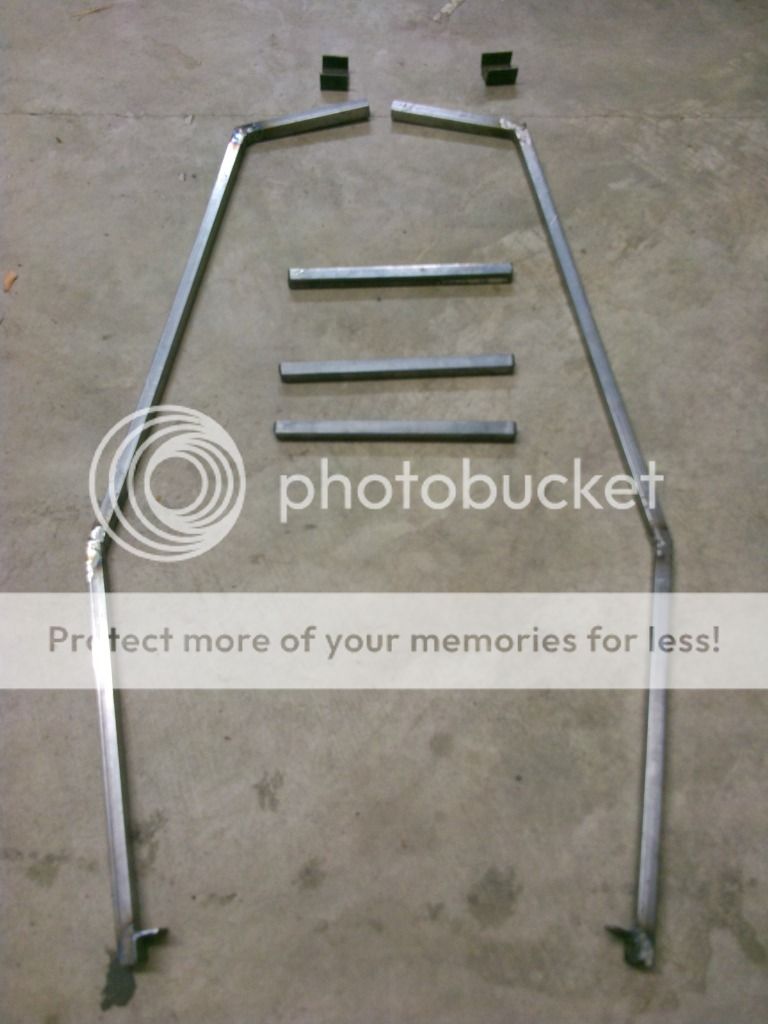

Pieces cut and laid out.

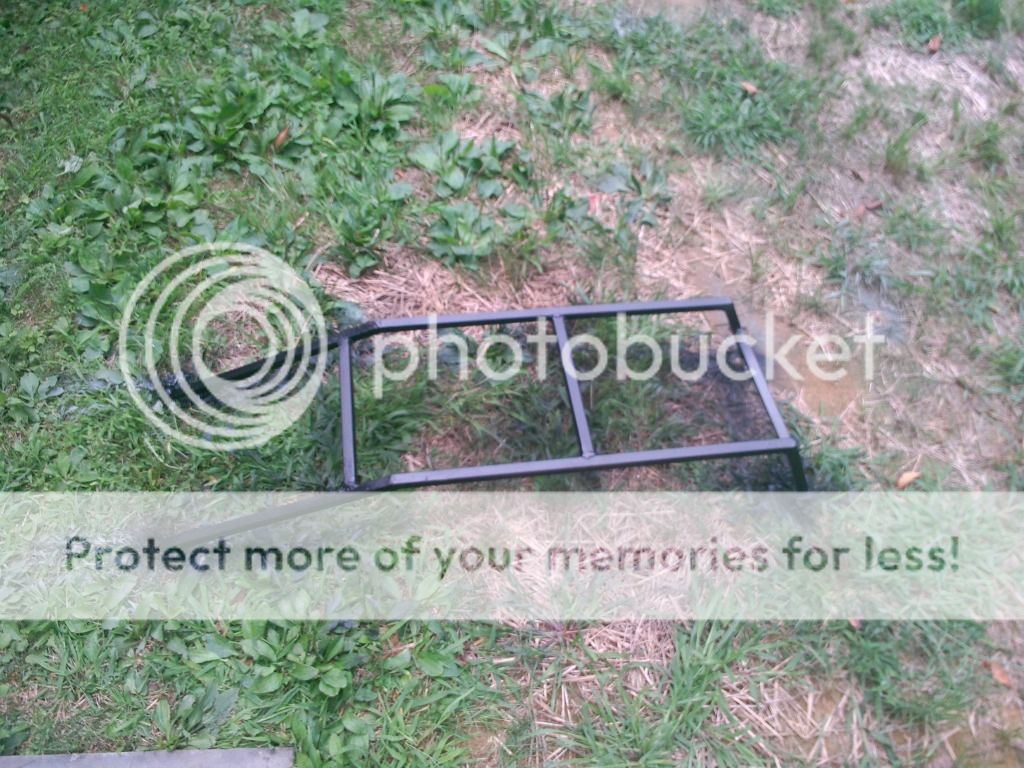

Welded together and sitting on the jeep.

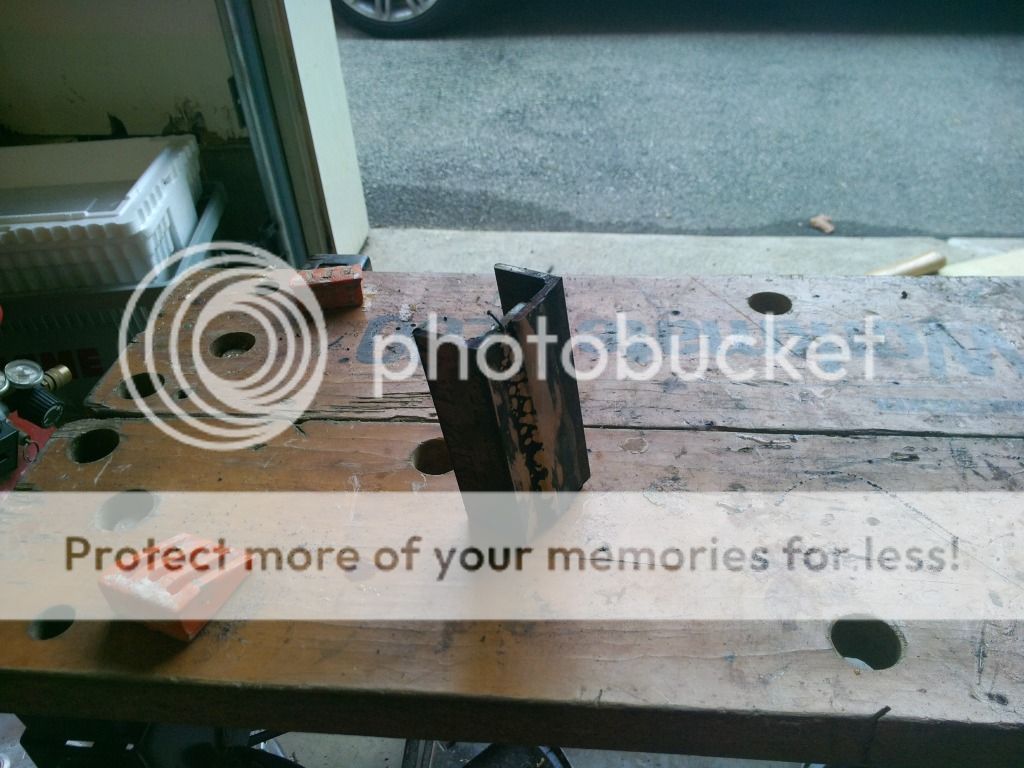

U bracket to attach ladder to roof.

Parts laid out. Tomorrow I'll well on the rungs and the clamps as well and grind everything smooth and paint it.

__________________

Picture of everything I used. Tools and materials.

Just mocked up to get angles and measurement

Pieces cut and laid out.

Welded together and sitting on the jeep.

U bracket to attach ladder to roof.

Parts laid out. Tomorrow I'll well on the rungs and the clamps as well and grind everything smooth and paint it.

__________________