DannyRoark89

NAXJA Forum User

- Location

- Vancouver WA

howdy folks this is my first post on  however i visit it most everyday, i am just getting fed up with the forum i post on normally so figured i would switch it up. im not a noob so through me your best shot on this

however i visit it most everyday, i am just getting fed up with the forum i post on normally so figured i would switch it up. im not a noob so through me your best shot on this

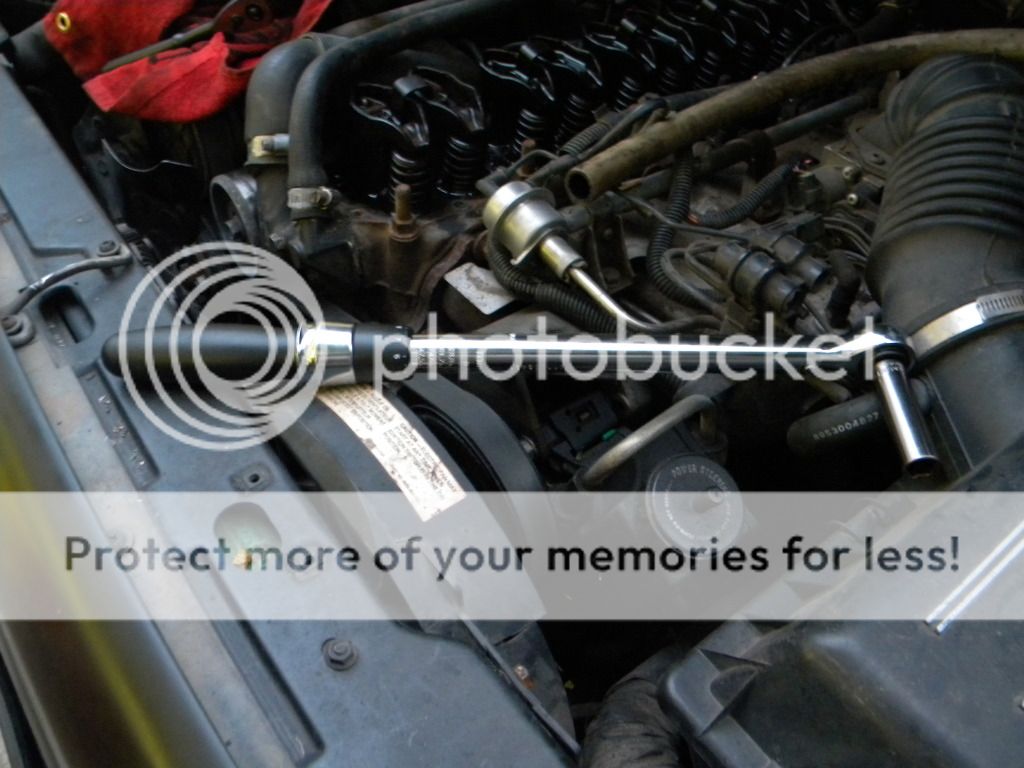

so here the scoop on the jeep. its an 89 with 189K miles and is actially closer to 195k ish i would assume based on when i was told the gauge cluster quit working. but its all good i got my own dash in their right now but the price was so good because the owner self diagnosed a broken rod to be the source of an awfully loud and chattery noise. and said he would take a fair price for it, and i was prepared to battle but he offered a price so good i just said sold heres the money. although the chatter is loud and annoying it wasnt a broken a rod i knew. his loss my gain, not my problem if he doesnt know what a broken rod sounds like.

got it home determined to get rid of the horrible noise. the noise is

loud compared to other ticking issues from the lifters or cracked or loose flex plates and bent rods that i have dealt with. if compared to anything it sounds like valves on a 4 stroke dirtbike engine that need major adjusting. thats what i thought anyway so i pulled the valve cover off and figured since it was out some high temp paint would make it a little brighter under the hood.

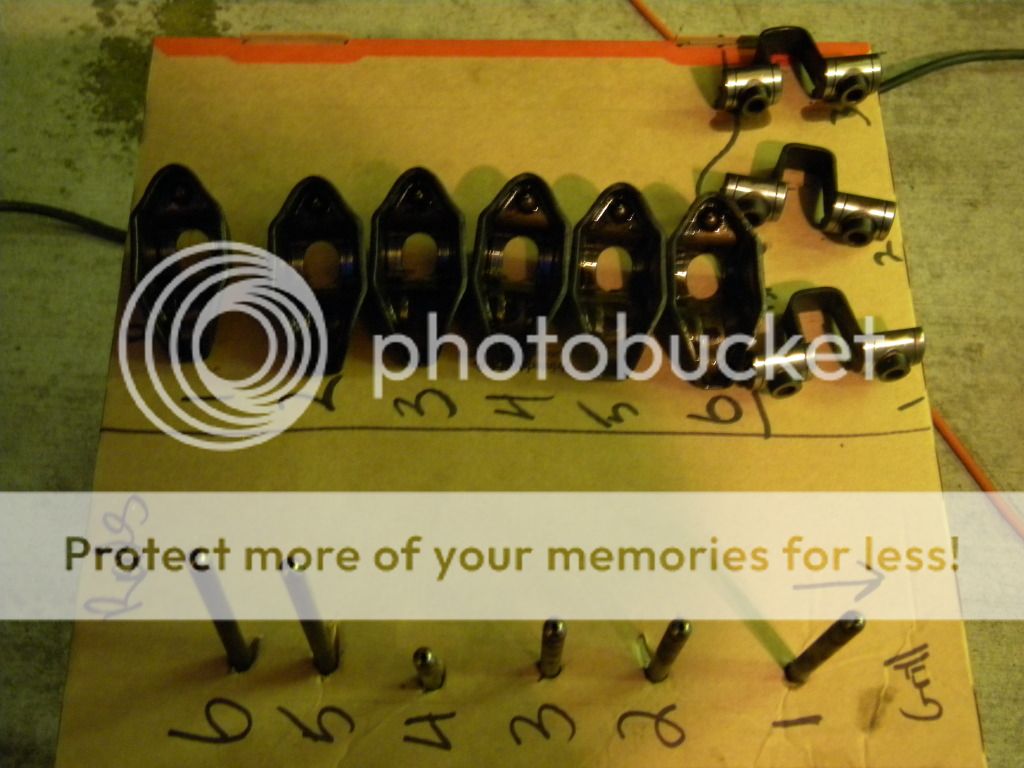

i started checking the rocker arms for play and movement or damage or anything that seemed out of the norm. i started in the back of the engine and worked towards the grill simply checking for play. when i reached the the rocker arm that is closest to the front grill i did have a slight amount of movement in the rocker arm. moving it by hand did create a mild ticking noise so common sense says if the engine is running at 3000 RPM then I imagine the ticking the would be proportionally louder right?

here is a video of the movement in the rocker arm (the Image is a link to the video on photobucket, ill put a direct link too incase im wrong)

http://s730.photobucket.com/albums/...s valve cover/?action=view¤t=forum1.mp4

i unbolted the bridge and re tourqued them to make sure that wasnt the issue and it wasnt. and although i believe my tourque wrench is fine as far as calibration i double checked with a beam style tourqe wrench. so now came the looking and pondering and looking over specs trying to decide the next step and also try and determine what caused this to happen.

When i was looking at it i thought it looked like the second rocker arm was sitting a little lower than the other ( but i also know that sometimes your brain tricks you when you look at something long enough)

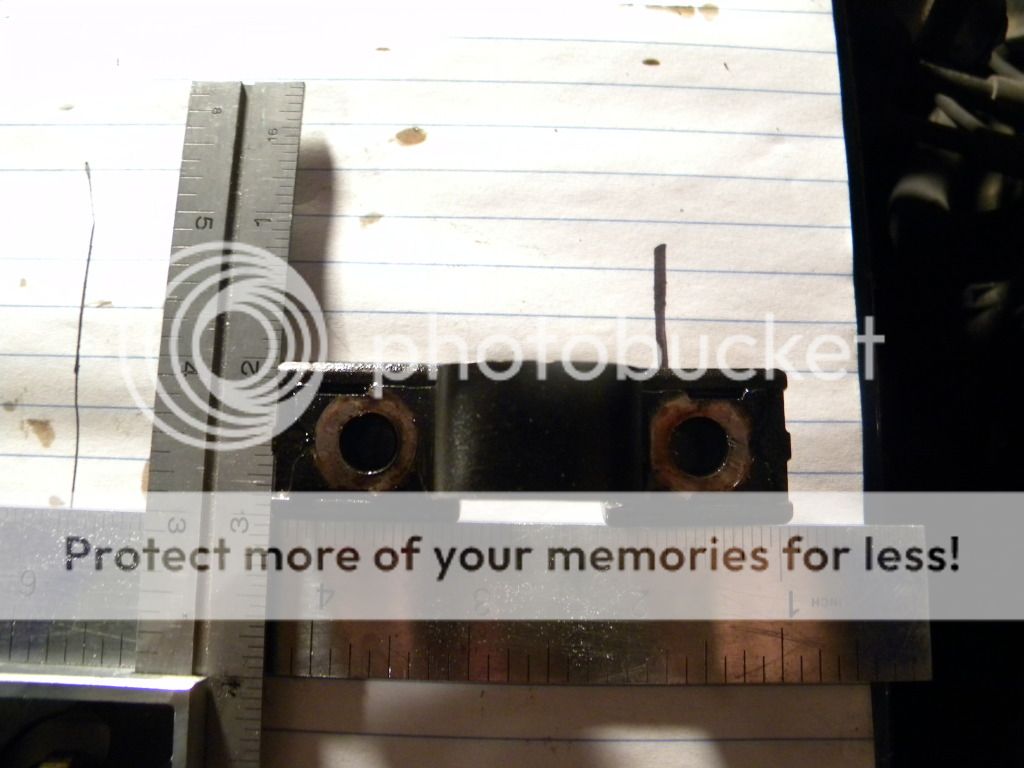

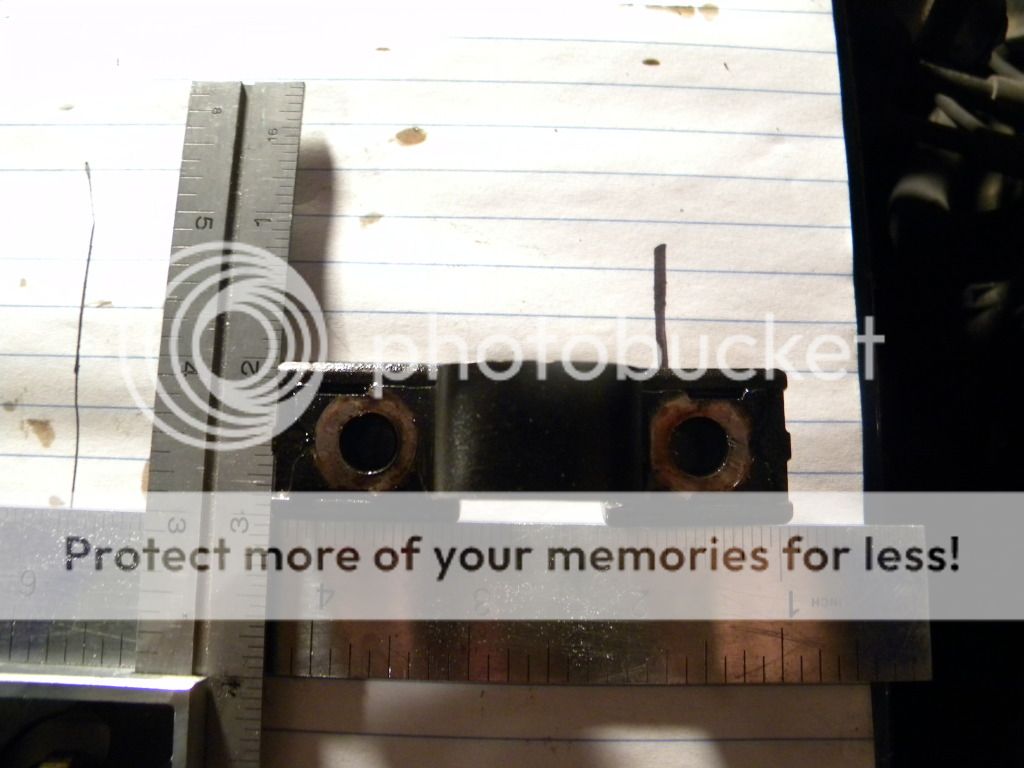

I pulled the bridge off the rocker arms to see if there was anything noticeably wrong with the rocker arm to allow the movement i felt. and as soon as i had the bridge in my hand it was apparent to me that it wasn't flat. heres a couple pictures of the twist that it has

here is a video too showing how far out of plumb it is

http://s730.photobucket.com/albums/...s valve cover/?action=view¤t=forum2.mp4

I pulled the rest of the bridges off one by one to see if any of the others were like this and they all were flat and square like the one below

my question is what would have caused something like this to happen? would replacing the bridge likely make the chatter go away? should i consider changing all the rockers and bridges (in which case i would do the lifters and rods and the 258 head)

my step dad mentioned that its possible part of the cam chipped off. I dont think thats the case the chatter is in the top end of the engine however it certainly wouldnt be the first time im wrong and hes right so im not enirely sure what to think.... i dont want to do a full rebuild yet, i am still a 6-8 weeks away from having the rest of the money and parts for a stroker

i havnt checked yet to see if the bolts for the bridge or fulcrum are straight or if the threads have been damaged on the bolts or the cast so that is one thing ill be looking at too

any and all info or thoughts are appreciated

thanks

however i visit it most everyday, i am just getting fed up with the forum i post on normally so figured i would switch it up. im not a noob so through me your best shot on this

however i visit it most everyday, i am just getting fed up with the forum i post on normally so figured i would switch it up. im not a noob so through me your best shot on thisso here the scoop on the jeep. its an 89 with 189K miles and is actially closer to 195k ish i would assume based on when i was told the gauge cluster quit working. but its all good i got my own dash in their right now but the price was so good because the owner self diagnosed a broken rod to be the source of an awfully loud and chattery noise. and said he would take a fair price for it, and i was prepared to battle but he offered a price so good i just said sold heres the money. although the chatter is loud and annoying it wasnt a broken a rod i knew. his loss my gain, not my problem if he doesnt know what a broken rod sounds like.

got it home determined to get rid of the horrible noise. the noise is

loud compared to other ticking issues from the lifters or cracked or loose flex plates and bent rods that i have dealt with. if compared to anything it sounds like valves on a 4 stroke dirtbike engine that need major adjusting. thats what i thought anyway so i pulled the valve cover off and figured since it was out some high temp paint would make it a little brighter under the hood.

i started checking the rocker arms for play and movement or damage or anything that seemed out of the norm. i started in the back of the engine and worked towards the grill simply checking for play. when i reached the the rocker arm that is closest to the front grill i did have a slight amount of movement in the rocker arm. moving it by hand did create a mild ticking noise so common sense says if the engine is running at 3000 RPM then I imagine the ticking the would be proportionally louder right?

here is a video of the movement in the rocker arm (the Image is a link to the video on photobucket, ill put a direct link too incase im wrong)

http://s730.photobucket.com/albums/...s valve cover/?action=view¤t=forum1.mp4

i unbolted the bridge and re tourqued them to make sure that wasnt the issue and it wasnt. and although i believe my tourque wrench is fine as far as calibration i double checked with a beam style tourqe wrench. so now came the looking and pondering and looking over specs trying to decide the next step and also try and determine what caused this to happen.

When i was looking at it i thought it looked like the second rocker arm was sitting a little lower than the other ( but i also know that sometimes your brain tricks you when you look at something long enough)

I pulled the bridge off the rocker arms to see if there was anything noticeably wrong with the rocker arm to allow the movement i felt. and as soon as i had the bridge in my hand it was apparent to me that it wasn't flat. heres a couple pictures of the twist that it has

here is a video too showing how far out of plumb it is

http://s730.photobucket.com/albums/...s valve cover/?action=view¤t=forum2.mp4

I pulled the rest of the bridges off one by one to see if any of the others were like this and they all were flat and square like the one below

my question is what would have caused something like this to happen? would replacing the bridge likely make the chatter go away? should i consider changing all the rockers and bridges (in which case i would do the lifters and rods and the 258 head)

my step dad mentioned that its possible part of the cam chipped off. I dont think thats the case the chatter is in the top end of the engine however it certainly wouldnt be the first time im wrong and hes right so im not enirely sure what to think.... i dont want to do a full rebuild yet, i am still a 6-8 weeks away from having the rest of the money and parts for a stroker

i havnt checked yet to see if the bolts for the bridge or fulcrum are straight or if the threads have been damaged on the bolts or the cast so that is one thing ill be looking at too

any and all info or thoughts are appreciated

thanks