GoBlue

NAXJA Forum User

- Location

- Southern MN

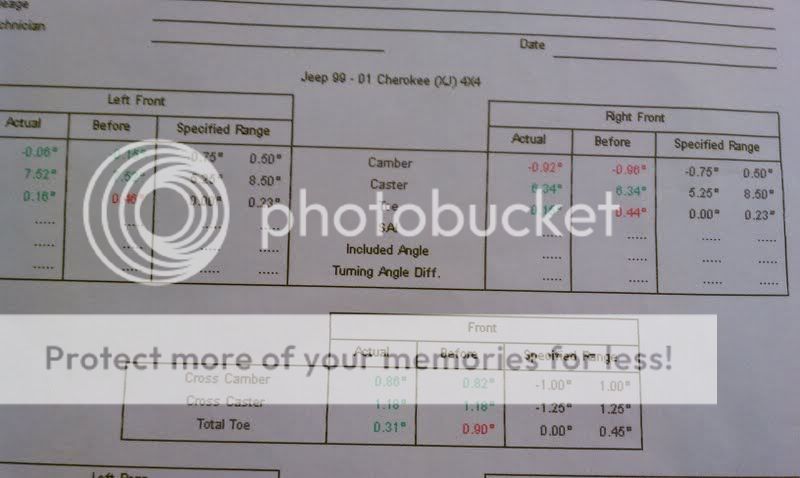

I just had my Jeep aligned and everything was in spec except the right side. The camber was .92 degrees (range is .75 -.50). My ball joints are brand new spicer brand. The tech said I should get an offset BJ (about 1 degree) and that should fix it. How does that happen on a solid axle?

More importantly, is the .25~ or so that its off enough to wear on my tires? Ill be putting the 31" General AT2's on there. Is the techs advice correct, and where do I get the BJ?

Info:

2000 XJ, 3.5" RE lift, Upper and Lower RE control arms, RE trackbar, Etc.

Thanks!

More importantly, is the .25~ or so that its off enough to wear on my tires? Ill be putting the 31" General AT2's on there. Is the techs advice correct, and where do I get the BJ?

Info:

2000 XJ, 3.5" RE lift, Upper and Lower RE control arms, RE trackbar, Etc.

Thanks!