Monster Mopar

NAXJA Forum User

- Location

- Moses Lake, WA

I just got finished setting up a used gear set in my rear axle. Since this is my first gear install I wanted to get a second opinion on my contact pattern.

Since it's a used gear set I'm supposed to go of the contact pattern on the coast side, right? If so I think it looks good but the drive side has me second guessing, I'm having a hard time disregarding it.

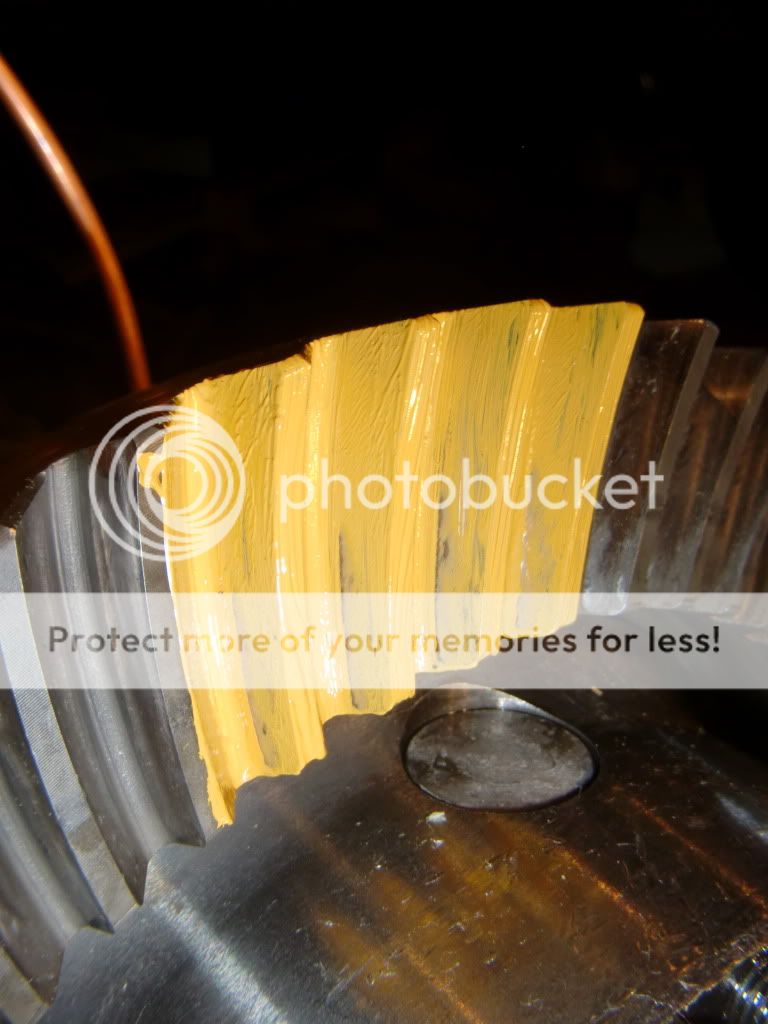

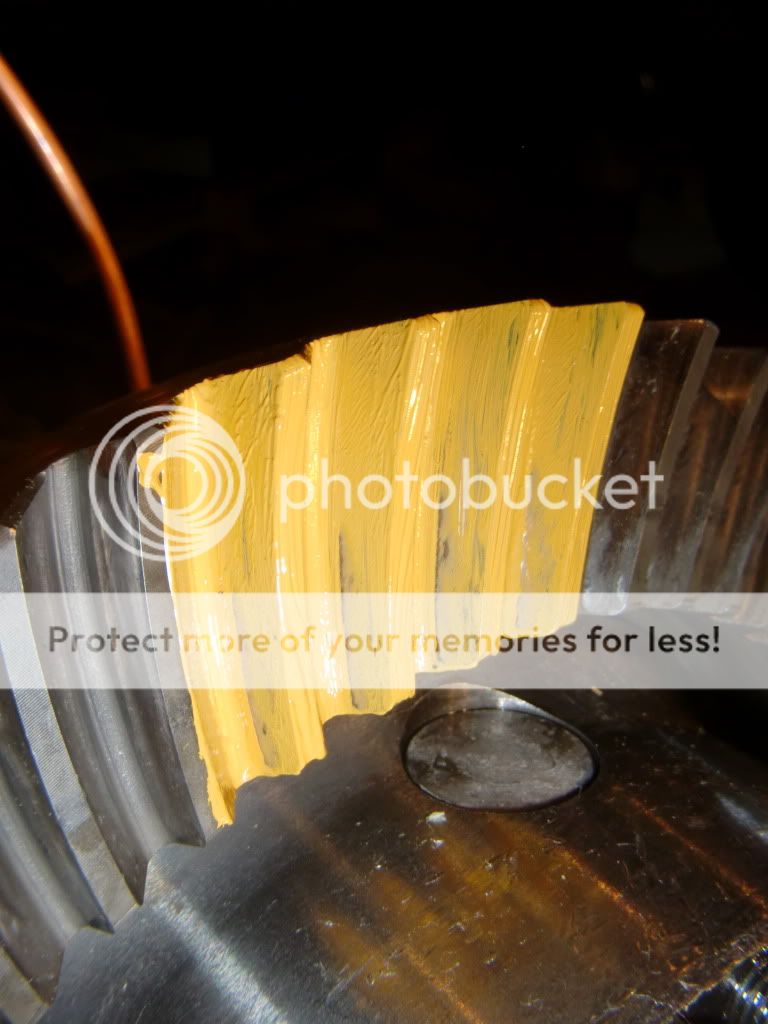

Here is the coast side:

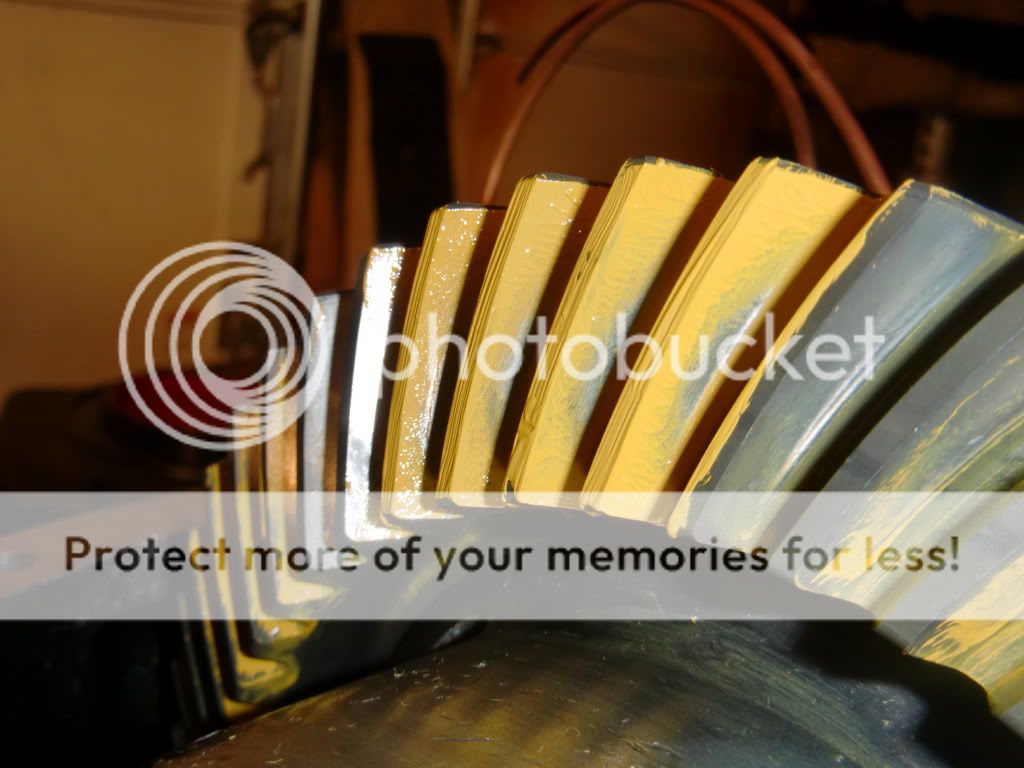

And the drive side:

Since it's a used gear set I'm supposed to go of the contact pattern on the coast side, right? If so I think it looks good but the drive side has me second guessing, I'm having a hard time disregarding it.

Here is the coast side:

And the drive side: