harmgrissom

NAXJA Forum User

- Location

- Maricopa, Arizona

since I got smacked around a bit with another question elsewhere I did do a search first and didn't find anything so :moon:

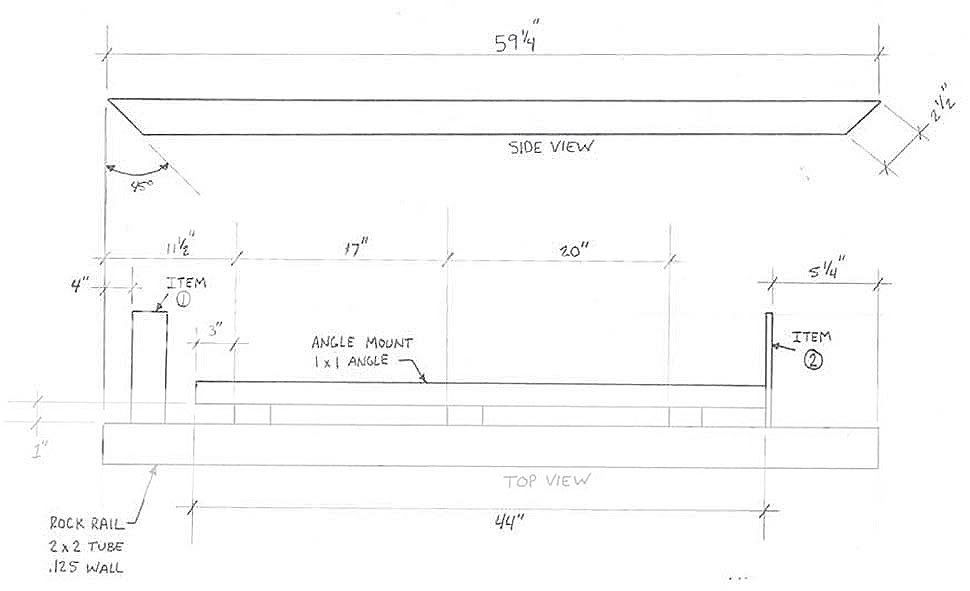

That said does anyone have any experience building rock rails or sliders themselves? I don't want to just buy them, I want to build them, both for cost reasons as well as experience.

How and where did you mount them underneath? Weld or Bolt? What kind of metal - size, shape, did you use?

Any info and advice that can be offered would be awesome.

FWIW - I'm not looking to go rock crawling and with the clearance and type of off-roading I do I don't expect to have a problem with actually needing them, more than anything I want/need to use them as an anchor for my hi-lift.

Thanks guys!

That said does anyone have any experience building rock rails or sliders themselves? I don't want to just buy them, I want to build them, both for cost reasons as well as experience.

How and where did you mount them underneath? Weld or Bolt? What kind of metal - size, shape, did you use?

Any info and advice that can be offered would be awesome.

FWIW - I'm not looking to go rock crawling and with the clearance and type of off-roading I do I don't expect to have a problem with actually needing them, more than anything I want/need to use them as an anchor for my hi-lift.

Thanks guys!