PoSxJ

NAXJA Forum User

- Location

- Portland, Or

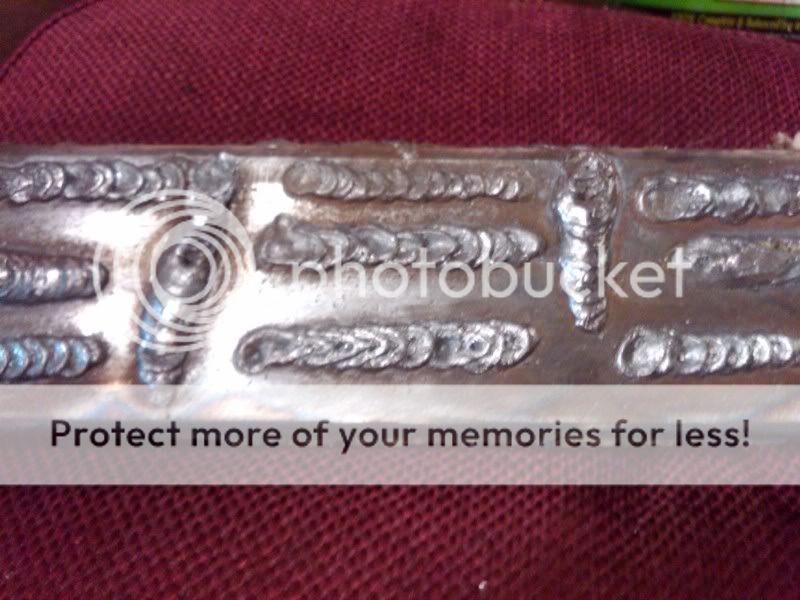

Bought a welder today. A Hobart 180 with a 80 cu ft tank. Going to the steel yard tomorrow to pick up some scraps to practice on. I need to fab my RK long arm brackets to work with my JCR sliders, since JCR sent me ones for a TNT LA kit. Then after that comes a rear bumper, and who knows from there. Ah, can't wait.

Here's the thread I started about the long arm brackets and sliders.

http://www.naxja.org/forum/showthread.php?t=1028855

Here's the thread I started about the long arm brackets and sliders.

http://www.naxja.org/forum/showthread.php?t=1028855