TheSandman

NAXJA Forum User

- Location

- Richmond, VA

So I'm starting to collect my parts for my front HP D44 build and just wanted to make sure I have everything straight.

My plan is to build a HP D44 on a somewhat budget, only going aftermarket when needed. I plan on running normal (no high steer) steering. I plan on using ford hubs and rotors to keep the 5x5.5 bolt pattern. Can I just use all ford outside of the inner C's? Meaning spindles, brakes, etc? I know most guys recommend chevy small bearing spindles, chevy caliper brackets and calipers, what's the benefit over the ford setup?

Also, stock outers are 19 spline, I've read that warn makes a 30 hub kit, where can I get ford 30 spline outers? Is it worth it to use them with stock wagoneer inner shafts? I plan on running longfield joints.

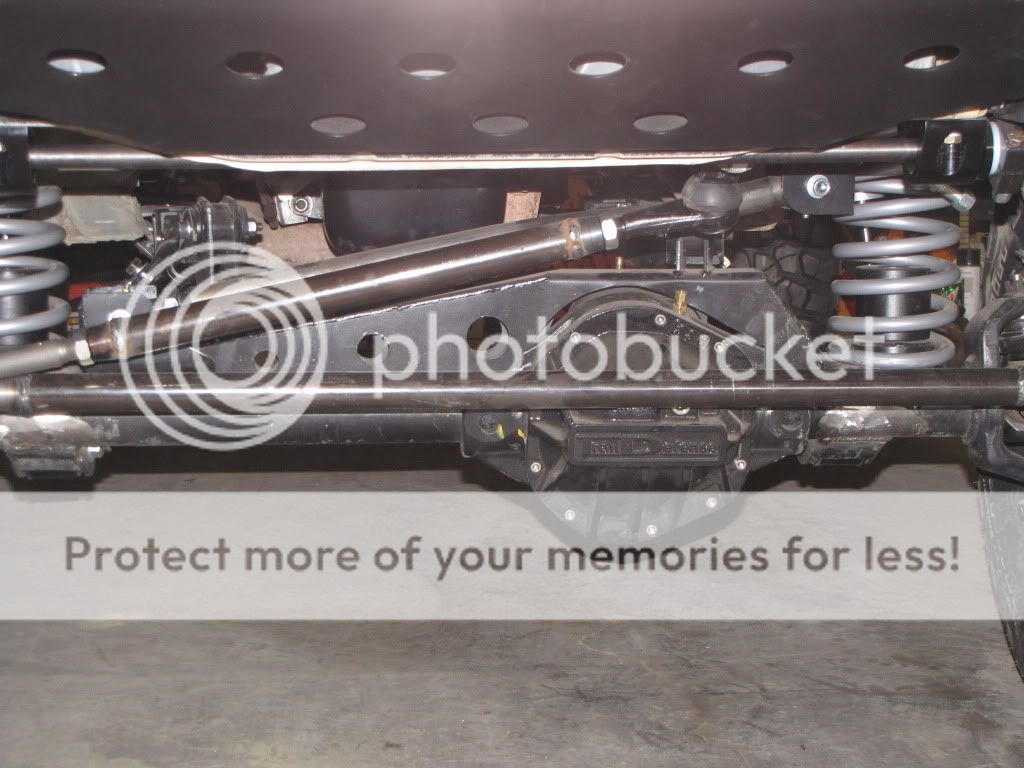

Next is bracketry, I know RE and clayton sells a full bracket kit. I was planning on running T&T's truss, but after reading some, looks like most people are having trouble with installing the truss and the axle being off center and the track bar mount will cause bumpsteer because of the short track bar. First off, isn't the coil bucket mounted on the truss? I understand you have to move the buckets out to center the axle?

I have 35's right now, will probably step up to 36 Irok's when they wear out, or even 37's at the absolute most. I'm a moderate wheeler, never heavy on the gas. I'm planning on running 4.88's and either a selectable locker, detroit, or even a lock right. The rear I have is a XJ D44 with a true trac.

Any comments or critiques are appreciated.

My plan is to build a HP D44 on a somewhat budget, only going aftermarket when needed. I plan on running normal (no high steer) steering. I plan on using ford hubs and rotors to keep the 5x5.5 bolt pattern. Can I just use all ford outside of the inner C's? Meaning spindles, brakes, etc? I know most guys recommend chevy small bearing spindles, chevy caliper brackets and calipers, what's the benefit over the ford setup?

Also, stock outers are 19 spline, I've read that warn makes a 30 hub kit, where can I get ford 30 spline outers? Is it worth it to use them with stock wagoneer inner shafts? I plan on running longfield joints.

Next is bracketry, I know RE and clayton sells a full bracket kit. I was planning on running T&T's truss, but after reading some, looks like most people are having trouble with installing the truss and the axle being off center and the track bar mount will cause bumpsteer because of the short track bar. First off, isn't the coil bucket mounted on the truss? I understand you have to move the buckets out to center the axle?

I have 35's right now, will probably step up to 36 Irok's when they wear out, or even 37's at the absolute most. I'm a moderate wheeler, never heavy on the gas. I'm planning on running 4.88's and either a selectable locker, detroit, or even a lock right. The rear I have is a XJ D44 with a true trac.

Any comments or critiques are appreciated.