Talyn

NAXJA Forum User

- Location

- Radford, Communistwealth of Virginia

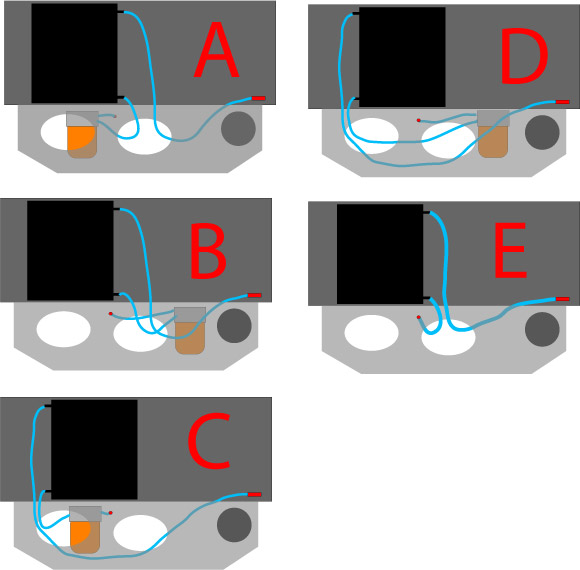

I'm moving my cooler from the driver side in front of the e-fan to the passenger side in front of the mech fan, similar to the stock location. I will also be pointing the hose barb fittings down. I'm doing this because a) better cooling at low speeds, b) with the cooler on the driver the hose has to make too many sharp bends and an excess length of hose is needed. I will also be cutting and flaring the hard line that runs under the oil pan (supply line) so it will point toward the front, like the return line already does. That will give the hose a straighter path to the cooler. The quick disconnect and soft line on the return line will also be replaced using threaded fittings. The quick disconnect at the lower radiator fitting will remain just because I don't know what else to do with it. BTW, I hate quick disconnects.

I'm going to be using Parker 836-6 Pusk-lok 3/8" hose. That way I can use either Russell's Twist-lok AN fittings of Parker's Push-lokT fittings.

I haven't decided on going with AN, NPT, or other. Suggestions? Any reason to go with one type of fitting over the other?

Also, I am considering putting a transmission remote filter under the radiator behind the front panel. Any thoughts on the filter?

-Chris

I'm going to be using Parker 836-6 Pusk-lok 3/8" hose. That way I can use either Russell's Twist-lok AN fittings of Parker's Push-lokT fittings.

I haven't decided on going with AN, NPT, or other. Suggestions? Any reason to go with one type of fitting over the other?

Also, I am considering putting a transmission remote filter under the radiator behind the front panel. Any thoughts on the filter?

-Chris