bigblueishness

NAXJA Forum User

- Location

- Winterville, NC

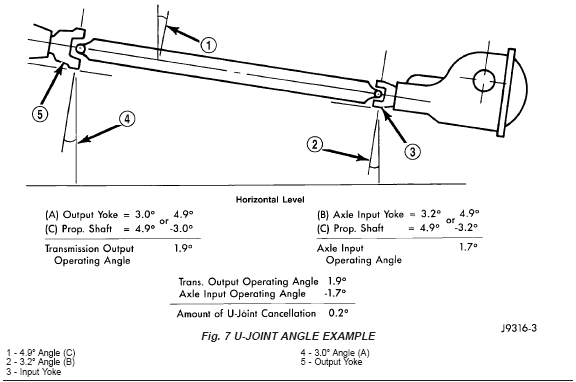

so i finished putting on my 3.5 inch lift, put my stock tires back on after done, drove it, viberates in the back at 20-42 mph, so I buy shims/wedges 6 degree put them on and nothing changes  ,

,

so would a t case drop fix that and how big of one, or is that just a band-aid for the viberation or do I buy a SYE and a new drive shaft

then got new wheels and tires, new to me, BFG A/T 31/10.50/15 all tires worn differently, now I have a wobble in the front goin 50-62, what can I do to fix that

by the way

stock track bar, steering

front sway bar is not connected

thanks for reading

alex

so would a t case drop fix that and how big of one, or is that just a band-aid for the viberation or do I buy a SYE and a new drive shaft

then got new wheels and tires, new to me, BFG A/T 31/10.50/15 all tires worn differently, now I have a wobble in the front goin 50-62, what can I do to fix that

by the way

stock track bar, steering

front sway bar is not connected

thanks for reading

alex