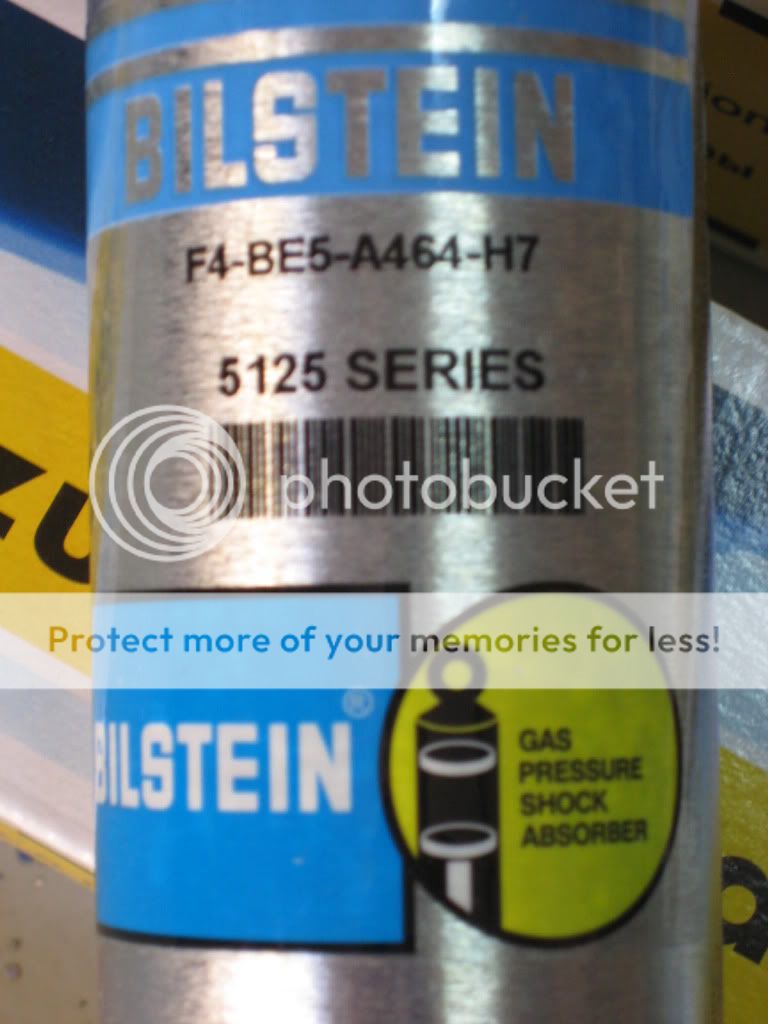

I finally got fed up with my Jeep riding like a cement truck so I purchased the Iron Rock Critical Path Long Arm Ultimate Ride kit. No one has done an install on here so I thought I would be the first. I did read Pbachs write-up on Off-road.com. It was very helpful and he convinced me to purchase this kit. $949.99 for long arms, crossmember and Bilstein 5100 series shocks. The shocks were back ordered and are being shipped now so I will update the thread when they arrive.

http://www.ironrockoffroad.com/Merc...en=PROD&Store_Code=IROR&Product_Code=IR-X_URK

Before I purchased I called Iron Rock and asked a ton of questions, all of which they kindly answered. I was concerned about my JCR Stage II rocksliders interfering with a long arm set-up. Since I welded the sliders on, the long arm kit would have to work on my vehicle. Iron Rock assured me that it would fit and even took a close-up photo with measurements so I could be sure. The crossmember it turns out acts like a factory crossmember with one extra bolt hole per side.

My old set up. Procomp lca and factory uca. 4.5" lift

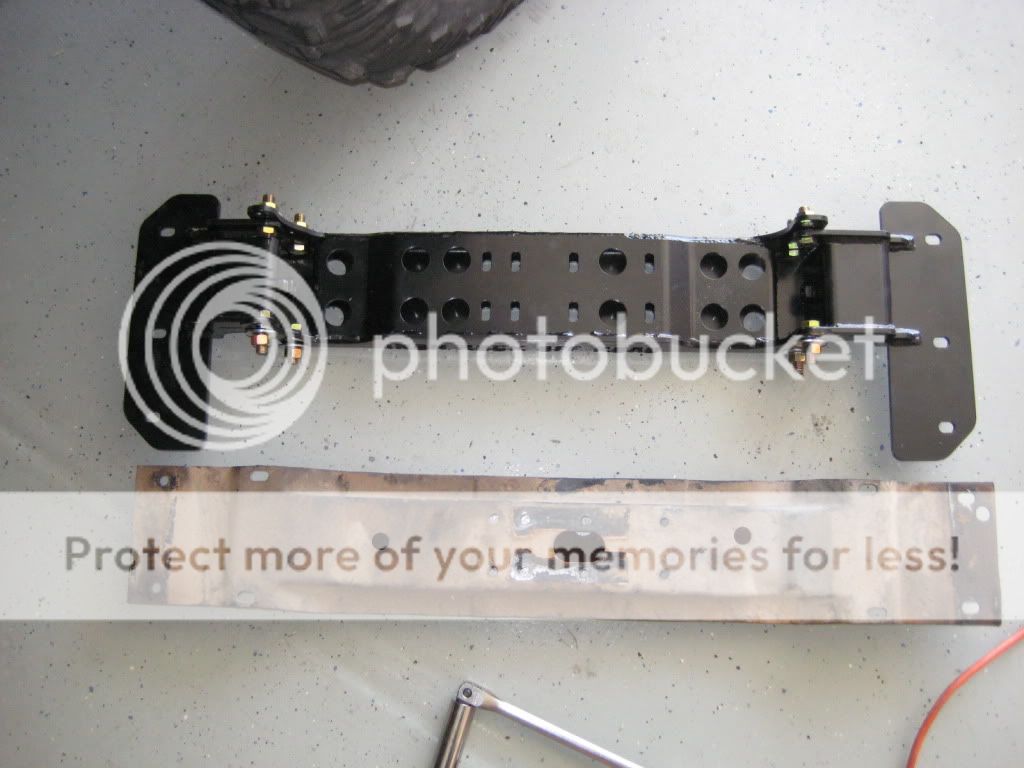

Iron Rock kit. Not much to it, just the way I like it.

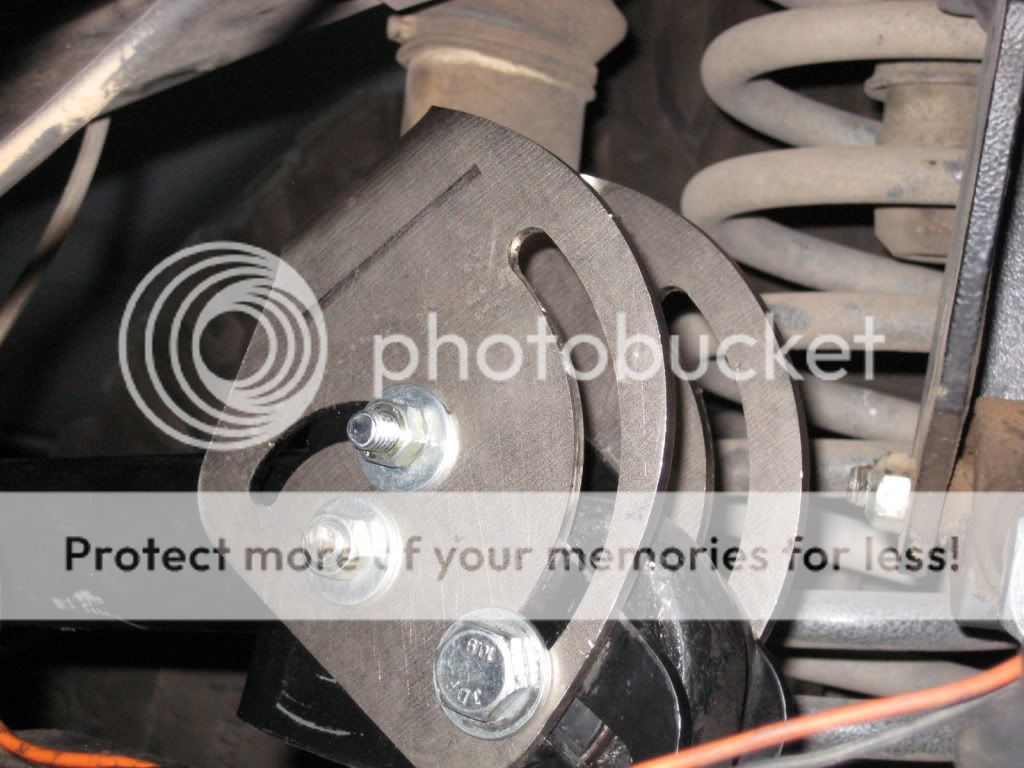

THis is the caster adjustment thingy. The instructions say to have the cambolts in the middle positions but mine are at either extreme. Maybe because I have the lowest lift for this kit. It is meant for 4.5" to 8". I'm guessing I did it wrong but it works for now. I have yet to take it for an alignment.

Long arms next to my 4.5" lift and 33" tires.

7/16-14 tap and 23/64" bit that is required but not included. This is for the extra hole needed for the subframe. It turns out that there is hole or bung right were this hole needs to be on my truck so I did not need to drill it, so I just tapped it.

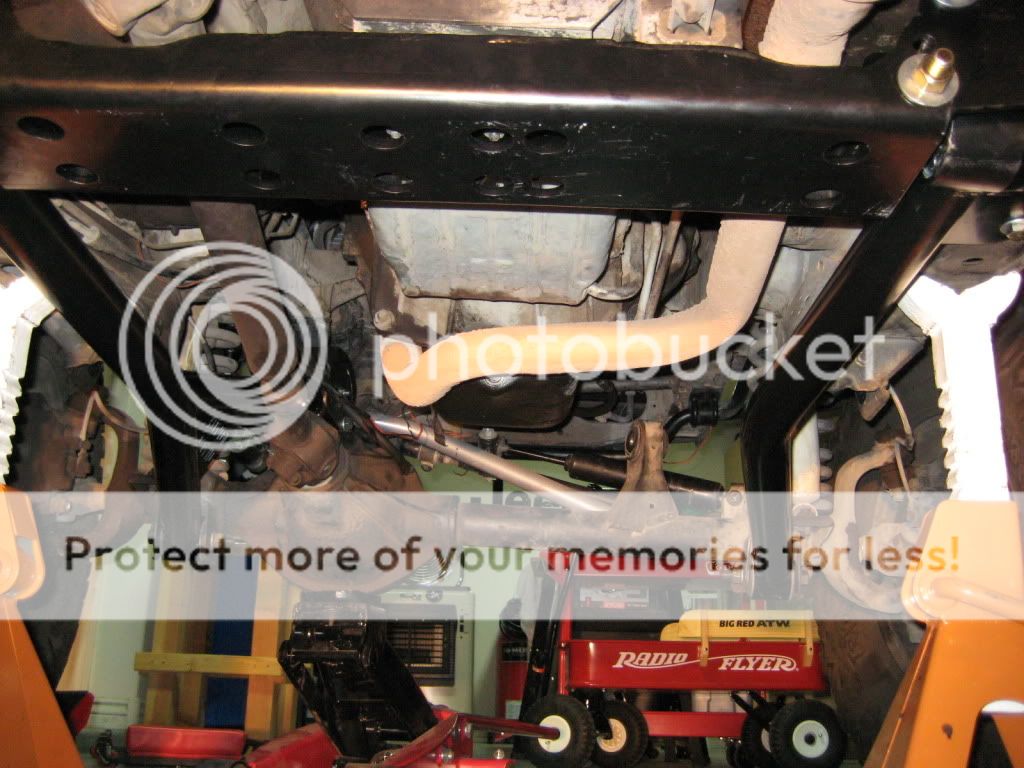

Subframe loosely assembled. Four 1/2" bolts hold it together.

http://www.ironrockoffroad.com/Merc...en=PROD&Store_Code=IROR&Product_Code=IR-X_URK

Before I purchased I called Iron Rock and asked a ton of questions, all of which they kindly answered. I was concerned about my JCR Stage II rocksliders interfering with a long arm set-up. Since I welded the sliders on, the long arm kit would have to work on my vehicle. Iron Rock assured me that it would fit and even took a close-up photo with measurements so I could be sure. The crossmember it turns out acts like a factory crossmember with one extra bolt hole per side.

My old set up. Procomp lca and factory uca. 4.5" lift

Iron Rock kit. Not much to it, just the way I like it.

THis is the caster adjustment thingy. The instructions say to have the cambolts in the middle positions but mine are at either extreme. Maybe because I have the lowest lift for this kit. It is meant for 4.5" to 8". I'm guessing I did it wrong but it works for now. I have yet to take it for an alignment.

Long arms next to my 4.5" lift and 33" tires.

7/16-14 tap and 23/64" bit that is required but not included. This is for the extra hole needed for the subframe. It turns out that there is hole or bung right were this hole needs to be on my truck so I did not need to drill it, so I just tapped it.

Subframe loosely assembled. Four 1/2" bolts hold it together.