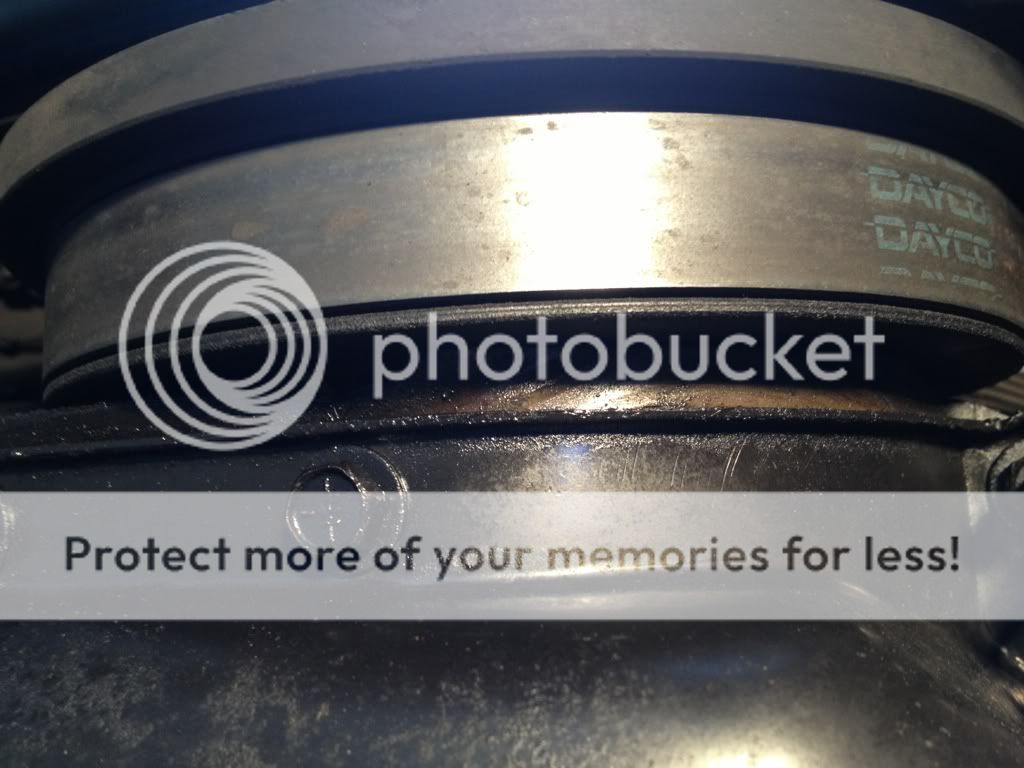

Thought I'd update the build a little. Obviously, this is gonna take more than a few weeks! Since I last posted, I reversed my previous decision to not do the front main seal. when I had the oil pan off to do the rear main, I wiggled the timing chain around and couldn't believe how loose it was. So, I pulled all the accessories off and replaced the front main and timing set.

So, after several trips to the parts store and the tool store, I was able to start putting the engine back together again. Embarassingly, I had to put the water pump on three times. The first time, I had forgotten to put the coolant tube into the new pump before bolting on to the engine- my fault, re-do. Next time, I had the coolant tube installed and bolted the pump up, and then noticed that the pulley flange was incorrect- the parts store gave me the wrong pump, re-do. That'll put some hair on your chest.

Then, as I was going to bolt the valve cover back on with a new gasket, I realized that I had thrown the washers away. I thought that I was getting new washers with the new gasket, but all I got was the rubber washers, I needed to re-use the steel parts. This spawned a trip to the junkyard. A lot of trouble for some measly washers, especially after the nearby Pick-N-Pull didn't have any of the washers and I had to go all the way across town. However, while I was there, gathering what I found to be rare washers, I saw a clean WJ that had just arrived. I had been wondering what I would ultimately do about my steering, and had just about written off the WJ swap as being too time consuming. But when I saw all the parts there, right in front of me, in perfect condition, I couldn't pass 'em up.

I'm no stranger to junkyard improvisation, but for the life of me I couldn't get the knuckles off on the first day. Let this be a warning to you if you bring your Fisher Price tool set to pull an axle in a junkyard, the inner set is what I brought the first day, the outer set is what I brought after those failed:

Anyway, I can't wait to get going on the axles, but I gotta do some grunt work first. I want to have the exhaust fab'd up and complete before I bolt the new TNT belly pan up there for good, so that's where I'm headed next. I spent a good bit of time cleaning up the stock trans mount to use for mocking up the exhaust (that engine oil leak was pretty bad). I also had time last weekend to have that bogus factory downpipe re-made. I cut the down pipe off of my exhaustt where it changed diameters to a larger pipe and brought it down to "Darrell's Economy Muffler". I was lucky enough to see Darrell himself, and with 28 years of pipe bending experience to his name, Darrell was able to pretty closely match the tight bends of the factory piece using a piece of 2 1/4". Check out the restriction in the last photo. I've confirmed, as another reader here suggested, that the dent in the downpipe is a factory feature and all Cherokees have this nonsense:

Unfortunately, I'm gonna have to dial back my committment to this project for a couple months. I'm taking the PE exam in April and need to start studying. I'll try to keep making time for it now and then and post up the progress. I'll hit it hard again after the test to get it rolling. Let's just hope I don't forget where everything goes in the mean time!